Matt Hale

In every situation where a heat exchanger is required, the combination of waste products and service fluids, application, temperature and other variables will be different. Understanding these properties, and how and why they affect heat exchanger performance, will enable project engineers to feed back the most relevant information to the manufacturer and ensure the correct exchanger is supplied.

Why Undertake Product Assessment?

Understanding the physical properties of a material will help to determine the best type of heat exchanger for the project. For example, high fouling products such as sludge may require a scraped-surface unit. It will also ensure that the heat exchange process does not alter the characteristics of the material, which may be an environmental consideration.

The Key Aspects of Product Analysis

The key aspects of product analysis are studying viscosity and flow behaviors, the study of which is known as rheology. This forms the basis of most of the tests required regarding the materials handled by heat exchangers, particularly in terms of consistency. Some of the key measurements that should be taken include:

- Viscosity

- Density

- Shear behavior

- Thermal behavior (e.g. specific heat, latent heat and thermal conductivity)

To ensure the correct heat exchanger is specified, it is recommended that the following measurements of different parameters are taken to model the product’s behavior and calculate key parameters:

- Apparent viscosity (the viscosity at a quoted shear rate)

- Heat transfer coefficient (the rate of heat transfer per unit area and unit temperature difference)

- Flow type at different conditions (i.e. whether the product displays smooth laminar flow or turbulent flow)

- Yield stress (the stress which must be applied to initiate flow of the material)

The way in which a product shears is also important and can determine the best type of equipment to prevent (or encourage) shearing during processing. The basic type of material will also be a key consideration—for example, sludges will be very different to water with clearly differentiated suspended solids.

How Are these Parameters Assessed?

Like most heat exchange engineers, HRS uses specialist laboratories often attached to universities to perform a range of tests, the exact nature of which depends on the product being tested and the potential forces and stresses that it will be subjected to during normal processing.

One of the key items of equipment is a rheometer; a specialist laboratory device which measures the way in which a liquid, suspension or slurry flows in response to applied forces. In order to adequately profile the viscosity and shear rate of different materials, particularly where there may be subtle changes, it is important to use a suitably sensitive rheometer which can detect very small changes and differences in zero-shear viscosity (the point at which viscosity stops increasing with reducing shear rate).

Another measurement, which relates to the potential effects of processing, is how (or if) the viscosity and structure of the material recovers after processing; a property known as thixotropy. Specific methods for assessing this, such as the ‘viscometric 3-step thixotropy test’ have been developed.

How is the Information Used?

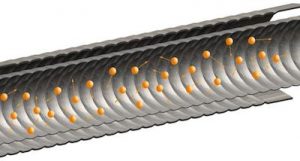

Once key parameters such as the viscosity and Non-Newtonian shear thinning factors are known, they can be used to select the best type of heat exchanger—for example, corrugated tubes will deliver heat transfer benefits in products which have a Reynolds number above 2,000 and which display transition or turbulent flow characteristics.

The measurements also allow designers to use heat exchanger software to calculate additional information, which is required for the design, but which cannot be directly measured in the laboratory. Some of the values which are calculated when designing a heat exchanger include:

- Heat transfer coefficient

- Flow type

- Nusselt number (Nu): The ratio of convective heat transfer to heat transfer by conduction in the fluid. Higher Nusselt numbers represent effective heat transfer.

- Prandtl number (Pr): The ratio of momentum diffusivity to the thermal diffusivity, representing the ratio of heat transfer to fluid motion.

- Reynolds number (Re): The ratio between the fluid’s dynamic forces and viscous drag forces. Value indicates the flow regime, i.e. whether the flow can be described as laminar, transitional, or turbulent.

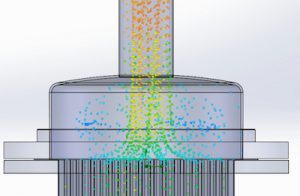

The various properties of the material are also entered into design and modeling software which uses computational fluid dynamics (CFD) to predict and study the flow of the product through the heat exchanger, and the thermal changes which occur. In order to do this accurately, the design temperature, pressure and maximum allowable pressure drop must be defined for the product and service fluids.

In short, the more information the manufacturer has on the physical properties of the materials involved, the more accurate the design of the heat exchanger will be. Our engineers and designers can adjust the design of the heat exchanger until the optimal combination of efficiency, productivity and cost is achieved, before making any recommendation to the client.