More than 23 million tons of organic waste is generated in California every year, according to CalRecycle. When that waste goes to landfills, it creates greenhouse gas emissions as it decays. California laws require cities to reduce emissions from waste. The State has adopted the nation’s strictest standards for reducing organic waste (green waste and food waste) and the greenhouse gas emissions it creates: up to 75% within the next 5-10 years.

That is a daunting task for cities with limited resources. Many are turning to their waste haulers for a solution to meet the State’s timeline. Anticipating the current environment, Athens Services launched an ambitious plan a decade ago to develop and implement the most advanced organic waste processing technology available in the state. A lot has happened in those 10 years.

The Regulatory Environment for Green Waste Changed

From regulating green waste to organic waste to food waste, California laws over the past decade included the following:

AB 1826– Requires local governments to establish organic waste recycling programs. Also, it requires businesses and multifamily residences of at least five units that generate four cubic yards or more of solid waste per week to arrange for organic waste recycling services.

SB 1383– Goal: A statewide 75% reduction in organic waste from 2014 levels, and a recovery of 20% of currently disposed of edible food, both by 2025. Jurisdictions, haulers, and generators are required to implement programs to comply with the law by January 1, 2022.

AB 1594– Under the law that took effect on January 1, 2020, jurisdictions can no longer count green material used as alternative daily cover (ADC) at landfills toward diversion. They are required to develop plans to divert green material from landfills.

Athens Services’ Solution

“Athens recognized that managing organics would become a key component in achieving high diversion rates for cities to comply with the coming regulations,” according to Area Vice President Anthony Bertrand, who oversaw Athens’ plans. “Our vision was to build and provide a fully integrated organics program from curb to compost.”

The first step was to expand Athens’ American Organics composting facility in Victorville, CA, in 2009. By 2014, it was clear that the existing facility would require a greater capacity to meet increasing demand in the future.

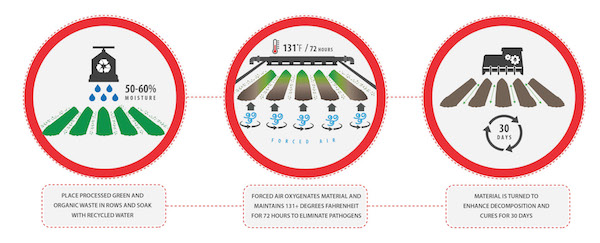

After an 18-month, nationwide search, Bertrand found the system the company was looking for: Covered Aerated Static Pile (CASP) composting. The CASP is an advanced system of composting that:

- dramatically speeds up the composting process,

- creates high-quality compost,

- and diverts at least 85% of organic waste from landfills.

The CASP system converts organic material rapidly without physical manipulation during primary composting. The blended mixture is placed on perforated piping, providing air circulation for controlled aeration. Also, it works well for processing wet materials and large volumes.

Thanks to the CASP system, American Organics can convert organic material into compost in about one-third the time of traditional methods. Currently, American Organics can process 460 tons a day; that capacity is expected to grow to 700 tons per day by the end of the year.

In its first few weeks of operation, the CASP system is achieving a diversion rate of 85%. American Organics anticipates the facility will reach an even higher diversion rate in the future. “It’s working far better than we expected,” Bertrand said. “It consumes less power, and the processing line is faster. It was designed to process 45 tons of green and organic waste per hour; it is already exceeding that.”

What does this mean to Southern California’s waste processing challenges? American Organics can process more green and organic waste in a shorter time while producing higher quality, contaminant-free organic compost.

Also, it removes tons of greenhouse gases annually. Recognizing the environmental benefits of the facility, CalRecyle provided funding for the project. The facility is estimated to reduce thousands of metric tons of greenhouse gases annually by diverting organic waste from landfills.

American Organics is unique among composting facilities in California. It is the first and only facility in California to process organic waste using fully automated conveyor belts and auger screens. And, it is the first to have a scalable, large-scale CASP system.

A More Sustainable Environment, The Athens Way

American Organics’ compost benefits Southern California by diverting organic waste, reducing greenhouse gases, and extending the life of landfills. And, its high-grade, agricultural compost benefits industrial growers and backyard gardeners alike.

In addition, Athens donates thousands of pounds of compost annually to the cities it serves for use at community parks, landscaping, and athletic fields, and residential use. By diverting green waste from landfills and converting it to compost, Athens gives back to the community while also helping cities achieve CalRecycle mandated diversion rates.

By the Numbers

- Amount diverted from landfill: 85%

- Tons processed per hour (per design): 45

- Tons actually processed per hour: 50

- Tons processed per month before CASP: 460

- Tons processed per month after CASP: 700

- Total composting time before CASP: 6 months

- Total composting time after CASP: 2 months