Misplacing permits, forgetting to renew them, and neglecting permit tasks are all problems of the past when you switch to a digital permit manager.

By Caroline Sharpless

Worker, vehicle, and facility permits can be tough to keep organized, especially when you are operating in multiple locations, across state borders, and have a revolving door of employees, contractors, and vehicles.

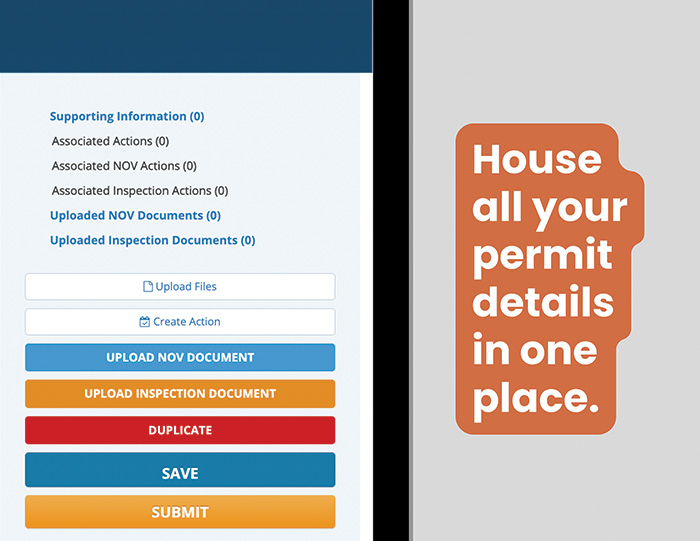

Administrators waste a lot of time flagging expired permits, tracking down new ones, or making sure permit tasks are being completed. Hours of busy work can be prevented by housing all your permits in one digital location. With an online permit manager, safety managers can organize and view all their permits from any computer, tablet, or mobile device.

Be Prepared for Inspections

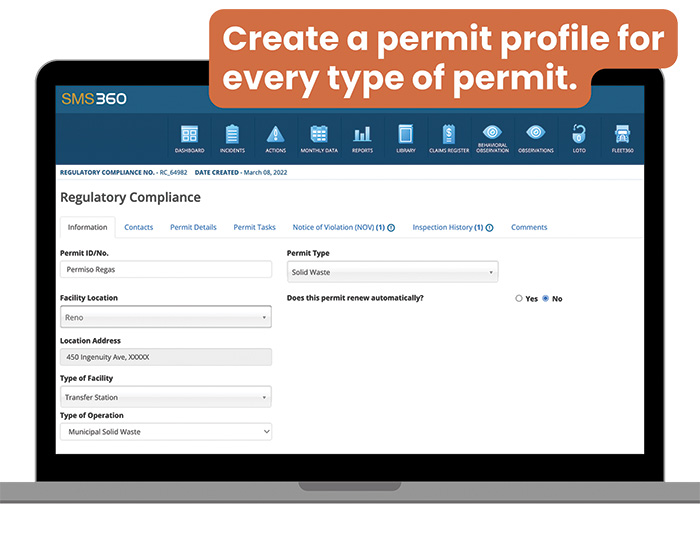

Digital regulatory compliance systems allow you to search for permits across multiple locations. Administrators can assign employees access to the system, and they can then log in and view the permits. They can filter the permits by name, age, location, type, and more. They can also export permit documents if needed.

In 2022, the EPA collected more than $300 million in penalties fines and restitution. With the new year, OSHA’s maximum penalties are increasing. Serious and other-than-serious violations will increase from $13,653 per violation to $14,502 per violation. The maximum penalty for willful or repeated violations will increase from $136,532 per violation to $145,027 per violation. If an inspector asks to see a permit, you want to make sure your employees can access them efficiently.

A digital permit library not only gives you quick access to all your permits if an auditor or inspector requests to see a permit, but users also do not need to scramble to find the correct permit. Some systems even store the old versions with each permit so a user can provide proof of the permit’s history. Within each permit, you can also view the inspection history and Notice of Violations. This is a good way to identify patterns if there are any repeat issues with a specific permit.

Never Get Fined for Expired Permits Again

It is worth investing in a regulatory compliance system instead of trying to do it on your own through Google Drive or Dropbox. The best digital compliance systems will automatically notify safety managers when a permit is nearing expiration. Administers can pre-set how far in advance they would like to be notified so they can have plenty of time to request new permits.

Some allow you to run reports to help you find patterns within your permits, permit history, or Notice of Violations. For example, you might find that a specific permit type is receiving far more Notice of Violations than others. Or maybe a specific permit task is never completed on time. This helps administrators identify operational inefficiencies, whether it is a location-based, employee-specific, or process-based problem.

Stay on Top of Notices of Violations

When you receive a Notice of Violation, the first thing you need to do is correct the action and show the regulatory body that you have righted the wrong. It is important to properly document this process so there is no confusion. Within 10 days of receiving the violation, a copy of the original Notice should be sent to the regulatory body with an additional explanation showing that the corrective action was implemented. This process is made easier when all of this correspondence is housed online. This way, other employees can login and access the violation rather than faxing it, e-mailing it around, or mailing it. If there are any disputes or issues, you have the proof documented in the system.

In the future, if another issue comes up with the same permit, it is easy to go back in and see how the past violation was handled and which actions were taken, as well as the people involved.

If violations are not resolved swiftly, businesses can be hit with serious fines. In states like California, companies can receive up to $1,000,000 in fines per day per violation.

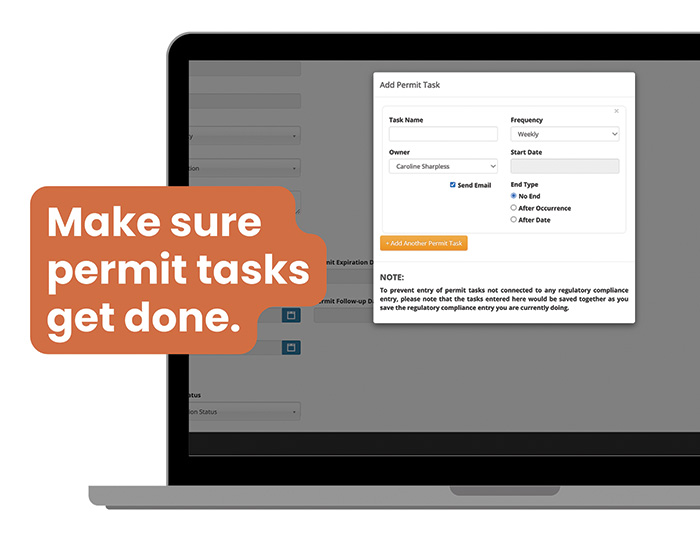

Make Sure Permit Tasks Are Completed

Some permits have daily upkeep tasks, while others require weekly or monthly actions. The best regulatory compliance programs will allow safety managers to track permit task activity. Regardless of the task or length or time, administrators can assign them to users and set requirements. They can decide how frequently users need to receive auto-e-mail notifications and whether the users need to sign off completed tasks.

This is a far better way of ensuring tasks are remembered and completed than clip-board charts, which often get lost, ruined, or forgotten. In the event of an inspection, the proof of permit task completion is also right there inside the Permit profile. | WA

Caroline Sharpless is Director of Marketing for SMS360, an EHS software platform that digitizes regulatory compliance and safety management. The team behind SMS360 has decades of experience in the waste industry and safety sphere. Companies across the globe use SMS360 to identify costly risk, operational inefficiencies, and compliance pitfalls. She can be reached at (203) 838-8877 or e-mail [email protected].

References

• www.epa.gov/compliance/how-we-monitor-compliance

• www.osha.gov/news/newsreleases/trade/01132022-0