As you are making your operational plans for 2022, it is important to implement fire prevention and reduction best practices and to invest in technologies and solutions that are going to keep your employees safe and your operations running more efficiently.

By Ryan Fogelman, J.D., MBA

Every industry faces fire risks, but in the waste and recycling industry, fires occur almost daily. These fires can spark from hazards such as pressurized tanks, chemicals, hot work activities, fertilizers, cigarette butts, and an emerging culprit, lithium-ion (Li-ion) batteries. If fire incidents are not detected and managed early, they can trigger a domino effect, presenting further risks to your employees and facilities.

These risks, if not addressed properly, are a real threat to any operation, as they can result in direct and indirect costs, including downtime of operations, potential injuries to employees, and difficulty finding reasonable insurance options.

In this article, I will provide an overview of the scope of the issue, the consequences, and the solutions available to address the problem the industry is facing on a global scale.

Scope of the Problem

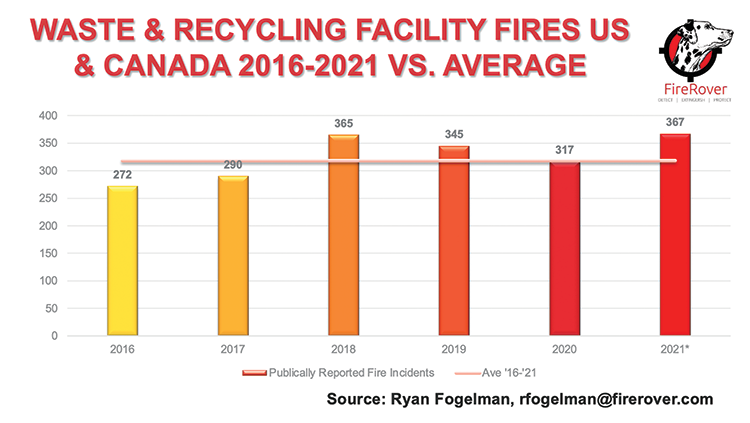

I have been tracking and consolidating the reported waste and recycling facility fire data in the U.S. and Canada since 2016. The numbers that seemed to never end in 2018 had come down, but in 2021, we hit a level that outpaced our worst year. In my opinion, the increase in fires is due to a number of factors, the continued proliferation of lithium-ion batteries on society, and the labor issues that are having a negative effect on sorting operations in our waste and recycling infrastructure (see Figure 1). This is concerning for several reasons. Dealing with a tight labor market typically runs in cycles and will hopefully fix itself over time, but there is nothing stopping the ever-compounding increase of lithium-ion batteries hitting the marketplace and eventually entering our waste and recycling streams. This is a problem that is not going away.

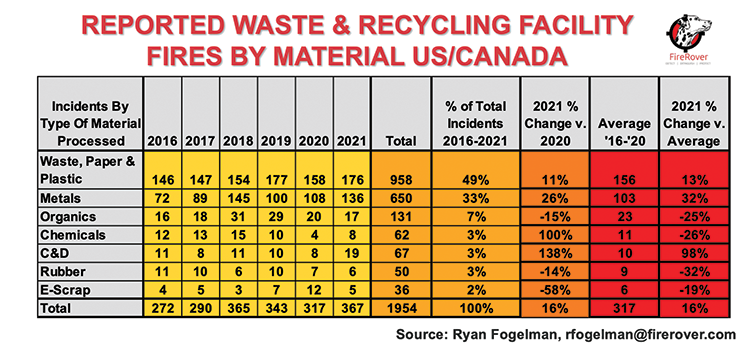

These fire incidents occurred across various types of waste and recycling facilities—municipal solid waste, paper and plastic recycling fires, and scrap metal fires increased and continued on their upward trend; construction and demolition (C&D) fires were up 138 percent year-over-year, and organics, hazmat, rubber, and e-scrap fires were down or in line with prior years (see Figure 2).

All of these incidents happened due to different reasons, but one common and growing culprit is lithium-ion batteries, which present many dangers and challenges for waste and recycling workers and facilities, especially if they are not disposed of or recycled properly.

This is a worldwide problem, and, unfortunately, without public education, the sharing of operational best practices and the investment in new technologies, the waste and recycling industry will continue to face many consequences and challenges.

Understanding the Consequences

Preparing your operation for fire prevention and operational best practices is just the first step in successfully dealing with fire risks. The second step is the onsite and/or fire professional response. The third step is proper investments in solutions and technology that will reduce the risk and severity of fire incidents.

One of the biggest consequences is the cost for these fire incidents, which I personally feel is unfairly borne by operators across the globe. Producers, on the other hand, are not currently burdened with this cost, as they manufacture and distribute batteries and then leave operators, fire professionals, and society to deal with the problems these batteries may cause. The manufacturers make small and insignificant investments in public education, but most of their capital is spent paying for lobbyists and associations that push their agenda.

A recent article published in The Wall Street Journal predicts that rechargeable lithium-ion batteries will transform the way the world uses power and disrupts industries, as demand continues to grow and prices continue to trend down. This prediction is in line with a recent report published by U.K.-based Eunomia Consulting, which predicts the problem of lithium-ion battery fires is only going to get worse, as more and more batteries come to market each year.

Of the 670 fires recorded by ESA waste management members across the U.K. in 2019 to 2020, 38 percent were either recorded as caused by Li-ion batteries or “suspected” to have been, according to the report. This is higher than the percentages recorded in the previous three years by the body (21 percent in 2016 to 2017, 25 percent in 2017 to 2018, and 22 percent in 2018 to 2019).

These fires not only pose risks to employees and facilities, but also come with a high price tag. According to Eunomia, the real cost of lithium-ion battery fires in the U.K. is about £158 million. Using my reasonable assumption for unreported fire incidents and taking into account the current exchange rate, the cost to the U.S. and Canadian waste and recycling operators due to lithium-ion battery fires is unfairly more than $1.2 billion. Since Eunomia’s study only associates lithium-ion batteries with about 50 percent of fires, which is in line with previous U.S. surveys, the real cost borne by our waste and recycling operators is realistically and conservatively about $2.5 billion annually.

These high costs, along with the industry ranking sixth among deadliest occupations, raise a red flag to insurance companies, which have been leaving the industry at a fast pace over the past few years. The fact is that insurance companies often leave an industry when they feel that the risks are not able to be controlled or there is no end in sight. But, to the waste and recycling industry’s advantage, technological solutions, such as early detection, have been reeling insurance companies back to the industry by helping operators have less fire risk than any point in history, including the time before the lithium-ion battery wave even began.

These real-life incidents are given solutions to provide operators with a leg up when it comes to negotiating coverage options with insurance providers; while insurance companies want to ultimately protect our industry’s occupancy, in reality they prefer to work with operators that are proactively addressing problems and investing in proven solutions.

percent on wind/solar power.

Photo courtesy of Fire Rover.

According to Stuart Kinsella, property underwriter at Rokstone Underwriting, who happens to provide insurance options to the waste and recycling occupancies across the U.K., U.S. and Australia, “For too long, the insurance providers within the waste and recycling arena have been writing business with inadequate pricing and inadequate risk management, particularly risk management that isn’t proportionate to the risk presented.

“At Rokstone Underwriting, we have developed and refined a process that is market leading, which looks at each risk in a multifaceted way—from understanding material types, process types, storage arrangements, and which risk management tools are most capable of dealing with the varying risks. We believe that recycling risks are not homogenous, and each requires an in-depth understanding. Through gaining this, we have built a robust program to cater to all ends of the hazard spectrum in the industry—from metal recyclers to alternative fuel production and everything in between.”

Proven Solutions and Technologies

To prevent and eliminate fire incidents, you need to invest in solutions that actually work for your facility type. This means that traditional fire suppression methods such as water sprinkler systems and smoke alarms may not be the best option to stop a fire at a facility where there is a lot of activity, such as a MRF, transfer station, or waste-to-energy facility.

Comprehensive firefighting solutions combat incipient fires and explosions within seconds from ignition. These systems are specifically designed for the waste and recycling industry and have eliminated more than 1,000 fires in waste and recycling facilities across the U.S. and Canada. There are many advantages to these systems and no two systems are the same. When researching these systems, one must focus not only on what the system offers in the brochure versus the actual reality of the solution. For example, there are a ton of AI systems on the market that promise huge results with no intervention but in real life they need to be “dumbed down” in the active environments we see in our waste and recycling operations. Knowing the different between the heat of a forklift versus a fire is one thing, but when fighting these fires, the human element can adjust their response for employee or professional response in real time. This response is especially important when protecting collateral assets or stopping the chain of fire events in lithium-ion battery processing operations.

Prepare to Be Prepared

As you are making your operational plans for 2022, it is important to implement fire prevention and reduction best practices and to invest in technologies and solutions that are going to keep your employees safe and your operations running more efficiently.

Without these preparations, an unfortunate incident could present unexpected costs, operational downtime and danger to your biggest asset—your employees. I encourage you to take action now and to be prepared. After all, good operators have fewer fires than bad operators, but new and innovative solutions are needed when good operators are still having fires. | WA

Ryan Fogelman, J.D., MBA, is VP of Strategic Partnerships for Fire Rover. Ryan is focused on bringing innovative safety solutions to market, speaking regularly on the topic of scope of the fire problem facing the Waste and Recycling Industry, detection solutions and onsite proactive suppression solutions. For more information, or if you would like a PDF copy of the “5th Annual Reported Waste & Recycling Facilities Fires in the US/Canada,” e-mail Ryan at [email protected] or message him on LinkedIn at linkedin.com/in/ryanjayfogelman. You can also purchase a hard copy on Amazon; all proceeds are donated to train firefighters on the risks of lithium-ion battery fires.