While smart technologies are already in use today, they will continue to get better and more affordable every day.

As smart technologies are becoming more a part of our everyday lives, their application in the collection and transportation of waste has become more of a reality. Waste Advantage Magazine reached out to those participants in the WASTECON 2017 Smart Technologies Keynote session to get their view on defining what those technologies are, understanding how professionals in the industry can take advantage of them and what the future holds.

What is currently understood in the waste and recycling industry as a smart technology? Which one in particular do you think is the most used and effective?

Don Ross: Smart technology is a broad term that loosely defines a number of software, hardware and other tools currently used or being developed throughout all aspects of the solid waste industry. Smart technologies are really about connectivity and exist today in collection, transfer, processing and disposal operations. They may include vehicle data collection systems and Controller Area Networking (CAN Bus), route optimization tools, new material sorting equipment and landfill compaction optimization, to name just a few. Route optimization is probably the most widely known technology, which got smarter as connectivity became more widespread. Better location-based data, reliable networks, and faster microprocessors have made routing solutions much faster and smarter. Route tools and new smart container capacity sensors are the basis for what will, over time, become a meshed data collection and customer service system, providing real-time, bi-directional, field data available for operations, fleet maintenance and customer service groups.

Don Diego Padilla: As discussed during our session at WASTECON 2017, “Smart Technology” has many meanings throughout the industry ranging from driverless cars to recycling and sorting robotics, to Internet of Things (IoT). In my opinion IoT is the most impactful as it connects most of these technologies and is the underlying technology that drives them. Put simply, IoT is about connecting and controlling the different objects in our world with the help of the Internet. With proliferating IT analytics, cloud computing, smart devices and apps, IoT is rapidly connecting businesses, processes and people on a scale that was previously inconceivable. IoT-driven Smart Truck technology—which connects your mobile assets (namely trucks) to your back-office billing, routing, reporting and mapping systems in real-time—has the greatest potential to measurably improve operations.

Jason Gates: It really comes down to the ability to automatically collect data and process it into actionable information. We’ve already seen the implementation of smart technologies like robotic sorting of recyclables resulting in higher quality materials and lower operating costs and telematics for trucks, like GPS and diagnostics, making for better driver productivity, improved safety and proactive maintenance scheduling. However, there’s still room to grow. A major area where smart technology has lacked, until now, has been in collecting and analyzing data on fullness and contents at the container level.

Antonis Mavropoulos: I think that for the time being the term “smart” in the waste and recycling industry has a rather limited and misleading use, in most cases related to several improvements achieved using digital advances. As a typical example, the use of a simple mobile app to inform and guide citizens on recycling is named “smart” recycling or the use of bins with sensors drives the evolution of “smart” collection. However, the real “smart” evolution of waste management is straightforward related with the gradual development of big data sets for the users of the system and the materials involved. These big data sets will allow to spot new patterns, to generate new business models, to develop new fit-for-purpose solutions and to revolutionize the waste management services in an unpredictable way. I believe that, until now, we can speak about three advances that are very promising: A) The emergence of hybrid waste collection systems (involving people, sensors, mobile apps, vehicles and storage equipment), B) The rise of robots based not only on sensors, but also on image recognition and analysis and C) The still underestimated but huge potential applications of driverless waste collection.

Marc Rogoff: In my opinion, the following three types of technologies/software are being used extensively in the solid waste and recycling industry:

- Customer Accounting Software—Accounting software is currently used by public and private operators to help in logistics, dispatch, manage customer communications and contracts, as well as billing and payments. When these accounting software tools are integrated with some of the smart technologies discussed, the organization can use the “Big Data” generated by these software programs to create efficient workflows and set efficient pricing for waste management services.

- Routing Optimization—Since its introduction in the early 1990s, innovative route optimization technology has been used throughout the U.S. by both private and municipal operations to streamline solid waste collection and monitor fleet performance. Saving on significant operating expenses like equipment costs, labor and fuel drives the need for waste collection operations to increase efficiency by reducing the number of routes, labor hours and mileage through route optimization technology. The three benefits of solid waste routing include improving efficiency, potentially reducing the number of vehicles out on the road and also future replacements, and improving morale through balancing routes across a solid waste collection system. Three challenges include data and information availability, buy-in by staff to help implement the results, and decisions on the software to be used and whether it is a purchase or cloud based. Waste routing software is typically complex to implement and has a high rate of failed implementations by municipalities. Typical complaints we have heard include: the software is too complicated to be adopted into daily operations, it is too expensive to purchase outright or procure through a monthly service fee, or the system maintenance requirements are too extensive.

- Smart Electronics—Collection vehicles are not easy to maneuver and this is in part responsible for the 6,000 or more accidents that are involved with every year. To solve this driver safety issue, companies like Waste Pro are installing high tech camera systems in all of their vehicles. Municipal solid waste departments and private waste management companies are increasingly buying radio frequency identification (RFID) tags and embedding them in solid waste and recycling bins. An RFID tag is like a barcode that can transmit its identifying numbers as a radio signal. This means that it is not necessary to see an RFID tag or even be close to it to scan it, as opposed to a barcode, which must be scanned with a handheld reader. Instead, small readers placed on waste and recycling trucks can automatically detect and read RFID tags. The readers are small radios with antennas that constantly emit a signal. When an RFID tag comes within range, the reader’s signal supplies the tag with the tiny bit of power required to activate it. The active tag transmits its data and the reader records it. The data on an RFID tag is a series of numbers that identify the object to which it is attached. A tag may also store the name and address of a trashcan’s owner as well as other information. The reader passes the information on the RFID tag to a computer database where software applications can put the data to use. Further, with the RFID system, a waste collection manager can view on the server when a truck is falling behind, based on the number of carts that have been emptied (contrasted with the number of carts on that vehicle’s route), or based on the address at which the cart is expected to be, thereby indicating the truck’s current location. Including this RFID technology in the overall residential collection system would require an investment for both the RFID tags on refuse carts and readers, preferably included with replacement automated collection trucks. The advantages to the operator would be substantial:

- Asset management—ability to track the location of the agency’s carts

- Data tracking and enhanced real-time productivity measurements

- Route visualization and intelligence

- Ability to target needed education and outreach for individual homeowners or neighborhoods

Dr. Vivek Agrawal: Information technology in collection and transportation of waste includes GPS, GIS, RFID and at a very few places sensors in bins to indicate quantity of waste. Out of these only GPS has a global use and being used mostly for vehicle trekking. It has substantially reduced cost of operation.

When did you really see the industry make the shift to smart technologies?

DR: Although it may seem like a revolution, the shift to smart technologies has been as evolutionary as the mobile telephone—30 or more years in the making. Route optimization has been around for nearly 20 years, but the technology continues to get better as cellular networking and GPS systems improve. The same is true for most smart technologies because all use connectivity and advanced microprocessors, which continue to get smaller and faster.

DDP: Municipalities are driving the adoption of technology within the waste industry. In the past three to five years, the Smart City initiative has gained noticeable momentum wherein cities are looking to use technology to better manage all systems and to provide more efficient, sustainable and accountable services to their citizens. Included within a Smart City’s mandate is waste management and the fleets that collect and dispose of this waste. With strained budgets and growing populations, being smarter about all aspects of waste management is becoming a growing priority.

JG: Technology has been used for a long time in our industry, but it’s only within the last several years that costs curve and new capabilities have made smart technology affordable and useful to deploy at scale, rather than in niche applications.

AM: The shift is on its way; it’s an ongoing process that we will see growing and redefining the waste sector. I realized that the digital technologies would completely transform what we call waste sector from around 2012 when I was working hard to create business models for mobile apps related to waste management. Back then I believed that mobile apps were the key driver for the next steps. Obviously, I seriously underestimated the revolution of sensors, the rise of robots and the potential of driverless cars. In 2013, when I realized that, I started to shape my ideas on the future of waste management and the 4th industrial revolution (http://wastelessfuture.com).

MR: As in other industries, solid waste has in recent years embarked on a quest to include “smart technologies” in everyday processes and programs. The objective for most municipalities and private haulers is to provide their services, cheaper and quicker, to their customers. My gut reaction is that the trend towards smart technologies escalated during the 2007 recession.

VA: With increased accessibility to smart phones and user engagement with social media, the shift has begun. It was long desired to bring efficiency and transparency in the system, but it is still in the initial stage. To be very honest, emerging economies have yet to adopt smart technologies except using GPS for vehicle trekking.

How have these smart technologies affected waste collection internationally?

AM: Waste collection is already affected in many cities. There are already millions of sensors installed in bins or other storage systems, measuring temperature, moisture and volume, identifying different materials and providing real time images with pattern recognition. We can already speak about the Internet of Bins and we have the Internet of Trucks on its way.

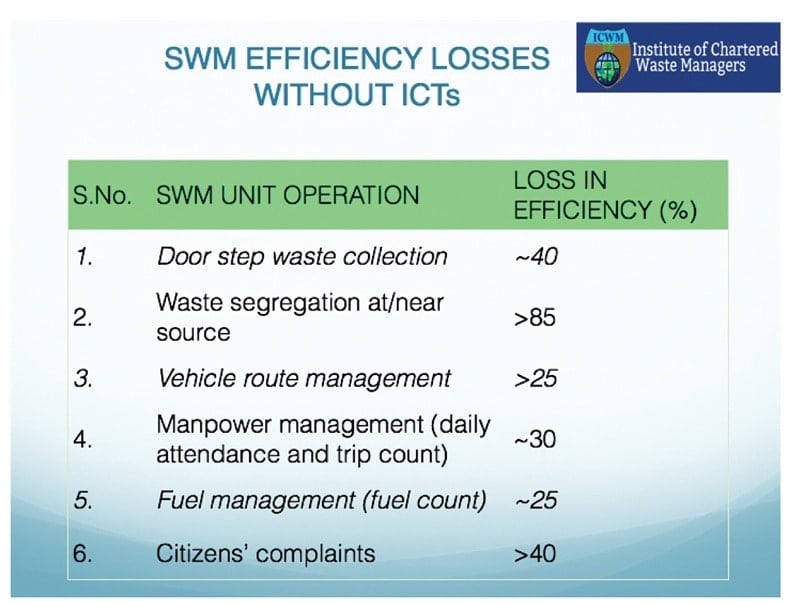

VA: The statistics in Figure 1 is for countries like India and alike. Use of ICT (GPS, Biometric and RFID to some extent) has addressed these losses positively.

DDP: The world is getting smaller. Technology is globally prevalent and enables advanced awareness and education. The sharing of best practices is often just a URL away. The more opportunity we have to engage and contribute internationally, the smarter we all get. As world urbanization and populations continue to grow, there will be an increased demand for intelligent, sustainable environments that reduce environmental impact and offer citizens a high-quality life. A 21st-century solution to waste management and collection is a key part of what makes up a “smart city”. Globally, waste management organizations are now progressively deploying industrial IoT systems to monitor trash, vehicles, drivers and customers to optimize many elements of the essential services offered.

DR: Different parts of the world are in different phases of solid waste industry development and, with that, the evolution of smart technologies. The benefit developing countries have is that they have immediate access to robust tools today, and can begin to enjoy the benefits of smart technologies right away.

JG: Smart technologies not only use information to create efficiencies, but also allow for data-driven regulations, more informed generators and accurate measurement of sustainability goals. Accurately applying the right data enables cities around the world to tackle Zero Waste initiatives. For example, the South Bayside Waste Management authority (SBWMA) in California, also known as RethinkWaste, is using fullness, content visibility, location, and service verification data to study current performance in their areas of operation and, in turn, make data-driven decisions on how to comply with state mandates, meet diversion goals, and improve operational efficiencies.

What are some of the current challenges and opportunities of smart technologies?

DDP: More efficient and sustainable waste collection is now considered a fundamental service for Smart Cities. Smart technologies can be applied to optimize waste collection with RFID tracking, sensors and cameras and more. Smart fleet systems now incorporate a model for connected data sharing between the back-office, trucks and drivers to enable route optimization, full management of container assets, safety and more efficient, sustainable operations. The challenge is that the adoption of smart technologies requires change management to operationalize the new processes required to make the organizational changes for sustainable improvement. Change management is a science and requires specialized personnel and processes to be effective. Therefore, having a technology provider that offers professional services to help the end user through the change management is invaluable and critical to the success of the technology deployment.

DR: One of the biggest challenges with smart technologies today is the lack of standards. Many different people are working on their own solutions, and many are working at opposite ends of the technology spectrum. Like any other technology, with widespread adoption, standards bubble to the surface. Think VCR vs. Betamax. We are closely watching those technologies that our customers request for installation on their vehicles. At some point in the future, OEMs will adopt the more popular technologies and standards will be created. We used to buy aftermarket accessories for our cars because the OEM alternative either wasn’t there, or wasn’t high quality. That changes as the best technologies become part of an OEM application. One of the biggest opportunities for smart technologies is the current strong economy and access to capital investment. Development can occur quickly with financial support.

AM: Cost is still a challenge, but as we see, it gradually becomes a secondary barrier due to the advances in efficiency. The development of big data sets from many different sources, with uniform data acquisition and management, is a real headache in many municipalities. We desperately need software solutions that will allow us to integrate data from multiple sources, with different formats, in one single information system. Another challenge is that the smart technologies require a supportive ecosystem to use them and so, even when the technologies are available and the costs are affordable and the public sector is not ready to adapt its operations to the new models. I am also afraid that many waste management companies are more traditional than required to invest in innovative technologies and transform their business models—in case they will not do it, most of them will not survive. Today’s profits are related with the tons managed—tomorrow’s gains will be related with the information managed.

JG: Cost is no longer a challenge for smart technologies—they are available and affordable right now, and this opens up opportunities to capitalize on reducing operational costs, maximizing resources and, ultimately, increasing the bottom line. The real challenge comes with the willingness to modify businesses processes to accommodate for the technology. It’s not always simple, and we give a ton of credit to the haulers, generators and regulators who have embraced the challenge to lead the industry in the right direction. The good news is we help ease the transition by guiding our clients through implementation, from install through tool training, and we’re seeing great success. We learn from our customers each time and continue to fine-tune the playbook for everyone else.

VA: Major challenges of smart technologies are non-availability of trained manpower, customization considering character of waste, topography, demography, cost of hardware and software. Also, it is too technical at some places. However, opportunities are enormous, as transparency, efficiency, optimization and reducing the number of grassroots functionaries demands smarter ways to handle waste with less human involvement.

How are they improving operations and customer services?

DPP: This is potentially a very long list! The top five improvements in no particular order are:

- Improved service verification

- Improved route efficiency

- Improvement in accurate and timely billing

- Improved maintenance and fuel savings

- Improved safety

DR: The financial payback has been proven with route optimization; collection routes are eliminated and productivity increases as routes are consolidated. Eliminating one collection route and the costs associated with it typically result in savings of more than $100,000 per year. As optimization gets smarter and becomes part of the entire data collection eco-system, however, real-time field data will empower customer service agents, dispatchers and fleet personnel to improve the business with the customer in mind. Missed pickups and costly rework can be eliminated, same-day or on-demand service will be done efficiently, and vehicles will communicate directly with fleet service departments pre-empting costly road calls and breakdowns.

AM: What we see is the almost endless optimization potential that arrives when you combine the data from all these different sources. Increasing customers’ satisfaction, improving efficiency and cutting cost is already spotted in many cases. This potential will stimulate the evolution of more on demand and customized services with less cost and better quality than today.

JG: Smart technologies reduce operational costs by identifying inefficiencies and streamlining operations. For example, image-based container sensors let front load haulers apply dynamic routing that could save 40 percent on operating costs. Similarly, roll-off haulers can be more in control of their routes by dispatching based on container fullness, serving customers as needed and reducing their cost of collection per ton. Haulers can also improve customer experience by sharing images with generators to verify service or resolve any dispute.

VA: User access to smart devices and increased involvement with social media have contributed towards improved operations and customer services. IoT will enhance it further. It has reduced response time to a great extent. Even in my personal experience, I have noticed sizeable reduction in fuel cost, duration of operations, maintenance cost, pilferage in worker attendance, and improved grievance handling besides client and user satisfaction.

How can waste haulers take advantage of these technologies?

DPP: Most fleet management technology providers have a scalable deployment process whereby the user can begin with a proof-of-concept deployment on a subset of the fleet or even the technology itself. You can start with one line of business, work through the change management and, once you have success, roll it out to the rest of the fleet. Or, you can start with part of the technology, such as a safety initiative with a DVR deployment, and then add to that routing, RFID integration, etc. over time. This is where a technology provider with a scalable entry-level smart truck solution is a big plus.

AM: Haulers and fleet managers need to know, with the highest accuracy, when (waste should be hauled), where (from which starting point to which destination), what (type of waste stream) and how much should be hauled. Now, not only can they have this information on real time in their mobile app, but also using artificial intelligence, predictive analytics and fit-for-purpose algorithms they can have a very good simulation of “what’s next” for one day, one month and later for one year. There is only one problem: they have to invest seriously in information technologies and big data.

MR: Waste haulers can take advantage of these technologies both in the front and back ends of their business cycle. Many do not recognize that the technologies themselves generate enormous amounts of data. In my opinion, adoption of newly designed customer accounting software is needed to optimize and provide cost savings and improved service to their customers.

JG: With more data, waste haulers gain valuable insight into their own operational performance. This can help haulers efficiently use their resources to deliver the right level and types of services to their customers. Ultimately, this means haulers will have the ability to do more with less, better service customers and save money at the same time.

DR: Haulers and fleet managers already know how to improve their business. Smart technologies help them do it faster and more efficiently.

VA: Use these technologies efficiently to monitor operations, creating a platform to understand coverage of services and microplanning for an efficient system. Based on experiences, alerts can be set to provide wake up calls about diversion, deviation, delivery of services, understanding customer satisfaction and using resources optimally. Also, they can plan operations with limited available resources. It also provides the basis for real-time monitoring.

What are the real costs and planning that goes into implementing these types of technologies?

DR: Up to now, I have extolled the benefits of smart technologies, but one of the biggest challenges is implementation and ongoing support of these tools. New technologies not only require a champion to help move the startup process forward and make change happen, but there also needs to be a commitment to resources that will support the systems on a day-to-day basis. Many folks have implemented technology but failed to commit the people to the process, and as a result have not been able to leverage the benefits that technology can offer.

DPP: The real cost is change management. The smart truck systems have a great ROI, but only after you operationalize the use of them. Depending on the size of the deployment, you should plan for a six to 12-month roll-out once the technology is deployed. If you’re going to maximize the potential benefits, you need to create an internal campaign for each improvement enabled by the technology, along with a critical path of implementation. It’s important to train each stakeholder in the organization as to what it means to them personally and what you expect of them—what their roles and responsibilities are and how their contribution will impact the overall results of the initiative. You need to be realistic in your expectations and, most of all, you need to be committed realizing that sustainable improvement is a marathon, not a sprint.

AM: There is a need to carefully plan the required interventions and gradually scale them up. It is necessary to see the impact at the whole system and not just at one of the phases of the waste lifecycle. My tip is the following: measure the expected impact not only in the technical aspects of the waste management system, but also at the social ones, including the changes required in the labor and the changes that the users will see.

MR: I am often called upon by local government providers to undertake collection feasibility and cost of service studies. These studies analyze the advantages and disadvantages of implementing smart technologies. The rate models I develop help provide the real costs of implementing these technologies both in the short and long term. Oftentimes, clients look at smart technologies as a means to defer rate increases and improve customer service.

JG: Process change can be difficult. Integrating technology into new workflows and getting the team onboard can be a challenge, and that’s why having an implementation plan is a major key to success. As a technology provider, part of the integration responsibility falls on us and our approach has been to not only provide a playbook for success and help support the integration team from step one, but to also make our tools as user-friendly as possible.

VA: At present, the initial cost is high, but upon doing a cost benefit analysis, it proves to be economical. It is desired to integrate a platform for all smart and information technologies instead of dealing with those in silo. Individual planning consumes more time instead of cumulative. It basically involves knowledge and intensive survey cost besides hardware and software. Operational and management cost is not too high. Steps are needed in the assessment, mapping of area (demographic, topographic, waste characterization, value chain and ecosystem of waste handling), services, diagnosis of deficiencies, desired performance levels, finding appropriate technology, integration of technologies, pre-testing and execution.

Where do you see the evolution of waste collection with regards to smart technologies?

DPP: Within the next 10 years, the majority of our fleets will be connected via IoT solutions. In fact, Cisco estimates that 500 billion devices will be connected to the Internet by 2030. Those that are not connected via IoT will simply no longer be competitive or operationally relevant. For example, poor driver safety stats have plagued our industry for years, which has made us the fifth most dangerous profession. IoT-driven smart fleet systems now come with multiple cameras for unprecedented insights into and all around a vehicle. Typically integrated with in-cab smart displays and mobile DVR devices—these cameras take pictures and capture real-time video footage for unprecedented remote monitoring. Fleet managers can now capture video of all internal and external activities from every angle, identify any driver-related safety issues for rapid remediation, capture evidence for accident and dispute resolution, and eliminate blind spot areas for a complete round-the-truck view. We’re going to see more and more of this connected monitoring so that fleet managers will benefit from an intuitive back-office view into what’s going on for each route, truck and driver, taking advantage of DVR functionalities. Additionally, information is knowledge, and collecting data with enhanced enterprise reporting tools will increasingly provide operations and performance statistics by tracking your company’s most important key productivity indicators. Managers will gain total visibility into all information at a macro company level right down to the individual driver level. This will enhance their ability to identify and solve problems faster, improve operational efficiency, better align their organization, spot service anomalies over time and much more. Smart, connected devices generate data that IoT applications will use to aggregate, analyze and deliver insight, which helps drive more informed decisions and actions. As an important next step in the smart evolution, we will see truck manufacturers increasingly offer complete and fully integrated smart trucks with onboard computing and back-office software systems pre-installed. These new, integrated smart trucks will make a compelling offering for waste management organizations by making it easier, more user-friendly and technologically seamless to operate a smart fleet. We believe this is now the next logical leap forward for waste management organizations.

AM: When people, bins, vehicles, mobile apps and algorithms are unified in a “smart” collection network, then optimization is just the starting point. Very soon, especially with the gradual use of driverless collection vehicles, we will have new business models that will radically re-invent waste collection and recycling. I believe that in the near future, in the world’s richest cities we will have separate waste collection for more and more different streams in an affordable way that will guarantee not only the diversion rates, but also the purity of the materials.

MR: All of these smart technologies offer communities and private haulers enormous opportunities in terms of helping them achieve the mantra of doing things quicker, cheaper and faster. It is a well-worn axiom that the future of technology is extremely hard to discern. For example, try to imagine explaining a tractor to a farm worker in pre-industrial America. The challenge in today’s world is to imagine that tractor being completely driverless. Yet, that time is almost at hand with most industries or with daily applications we are familiar. For example, what about driverless Ubers picking up passengers in Pittsburgh, giant combines mowing hay in North Dakota, 3-D printing or automated equipment turning off lights, air conditioning units, or security systems? Does that mean that human labor will “go the way of the horse”, as Nobel laureate economist Wasilly Leontief famously predicted? Perhaps. If one looks at industries that have been early adopters of automation and artificial intelligence (AI) or machine learning, it is clear that there has been a downsizing of labor. Technology is advancing exponentially and threatening to disrupt many industries including medical testing, finance, auto making, pizza delivery and even steelmaking, said Vivek Wadhwa, a futurist and the director of research at Duke University during a recent conference sponsored by the World Steel Association. Even in countries like India with high populations, the move towards automation and reduced labor per ton of steel has been a dominant trend as they attempt to stay completive in the world market. In no means do we have the answer for the solid waste industry because technology has always been a disrupter. Social costs will soon have to be addressed in the solid waste industry. With less employees and more productivity, the inconvenient truth is that the revenues for the social safety net as we know it (Social Security, Medicare, Unemployment Compensation Insurance, and Worker’s Compensation) may be significantly underfunded with less employed workers.

JG: While smart technologies are already in use today, they will continue to get better and more affordable every day. When you hear about the evolution of waste collection, it’s more often than not connected to reaching Zero Waste. Generators and regulators can make rapid progress towards Zero Waste by using smart technology to conduct content analysis on each and every container. Take the city of Los Angeles’ RecycLA program for example. To meet the goal of 90 percent diversion by 2025, Los Angeles is conducting 80,000 manual waste audits in six months (or roughly two audits per customer) to gather information on generator waste and recycling practices. While this approach made sense a few years ago, the technology to simplify this tedious process now exists and is affordable enough to implement. With image-based sensors in every container, the city could have true transparency into waste habits every day and be able to create data-driven solutions and provide targeted education to haulers that would speed up progress towards Zero Waste tremendously.

VA: Leading to Zero Waste Solutions through minimum resources with maximum output.

DR: All the different tools: the routing software, the in-cab device, the smart container sensors, the cameras, the vehicle’s engine and body sensors, and the customer facing portal that provides visibility to service, will become ubiquitous as a single system that eventually will be part of a vehicle or body manufacturer’s OEM equipment offering. These same systems are also the underpinnings of what will be required for autonomous driven vehicles. I’m excited for what the future holds!

Thank You to to Our Participants

Marc J. Rogoff, Ph.D., is Southeast Manager of Sustainable Materials Management for SCS Engineers. Marc has more than 45 years of solid waste and recycling industry experience from both a public and private perspective. He currently serves on the Executive Committee of the Solid Waste Association of North America. He can be reached at (813) 810-5547 or [email protected].

Marc J. Rogoff, Ph.D., is Southeast Manager of Sustainable Materials Management for SCS Engineers. Marc has more than 45 years of solid waste and recycling industry experience from both a public and private perspective. He currently serves on the Executive Committee of the Solid Waste Association of North America. He can be reached at (813) 810-5547 or [email protected].

“If you don’t measure it, you can’t manage it” is the age-old adage and words to live by according to Don Ross, who dedicates his work to advancing the science of waste collection to increase efficiencies, improve safety, and enhance recycling and waste diversion through the use of new technologies. Don leads the brand management efforts for McLaughlin Family Companies, including New Way Trucks, the fastest growing solid waste equipment manufacturer in North America. Prior to joining the McLaughlin team, Don served as a solid waste industry consultant specializing in collection and transfer operations. Don has more than 30 years of solid waste experience managing solid waste collection and transfer operations for both public and private sector organizations. Don believes that new technology can improve solid waste operations for the men and women in the industry as well as the customers they serve, and is committed to that endeavor. He can be reached at (712) 652-3396, via e-mail at [email protected] or visit www.mcfamco.com or www.newwaytrucks.com.

“If you don’t measure it, you can’t manage it” is the age-old adage and words to live by according to Don Ross, who dedicates his work to advancing the science of waste collection to increase efficiencies, improve safety, and enhance recycling and waste diversion through the use of new technologies. Don leads the brand management efforts for McLaughlin Family Companies, including New Way Trucks, the fastest growing solid waste equipment manufacturer in North America. Prior to joining the McLaughlin team, Don served as a solid waste industry consultant specializing in collection and transfer operations. Don has more than 30 years of solid waste experience managing solid waste collection and transfer operations for both public and private sector organizations. Don believes that new technology can improve solid waste operations for the men and women in the industry as well as the customers they serve, and is committed to that endeavor. He can be reached at (712) 652-3396, via e-mail at [email protected] or visit www.mcfamco.com or www.newwaytrucks.com.

Don Diego Padilla II is Vice President of FleetMind. A waste industry fleet management veteran, he is spearheads business and customer development activities. Previously, Don Diego was a Regional Sales Director for Allied Waste, now a part of Republic Services—a leading provider of solid waste collection, transfer, recycling and disposal services in the US. He is a frequent contributor to FleetSMARTS, an industry newsletter targeted at fleet organization executives. His white paper on fleet safety garnered a Network Products Guide Award in the “Best White Paper” category. Don Diego has been published in numerous industry magazines and is a frequent speaker at industry forums and regional municipal waste management events. He can be reached at (888) 639-1666, ext. 351 or via e-mail at [email protected].

Don Diego Padilla II is Vice President of FleetMind. A waste industry fleet management veteran, he is spearheads business and customer development activities. Previously, Don Diego was a Regional Sales Director for Allied Waste, now a part of Republic Services—a leading provider of solid waste collection, transfer, recycling and disposal services in the US. He is a frequent contributor to FleetSMARTS, an industry newsletter targeted at fleet organization executives. His white paper on fleet safety garnered a Network Products Guide Award in the “Best White Paper” category. Don Diego has been published in numerous industry magazines and is a frequent speaker at industry forums and regional municipal waste management events. He can be reached at (888) 639-1666, ext. 351 or via e-mail at [email protected].

Jason Gates is CEO and Co-Founder of Compology, a provider of waste industry software tools powered by container-mounted sensors that provide image-based fullness and content monitoring, GPS location tracking, and motion-based service verification to help make waste data accessible and actionable for haulers, generators, regulators and processors. Gates is a Waste360 40 under 40 winner and holds a B.S. in Civil and Environmental Engineering from the University of Maryland.

Jason Gates is CEO and Co-Founder of Compology, a provider of waste industry software tools powered by container-mounted sensors that provide image-based fullness and content monitoring, GPS location tracking, and motion-based service verification to help make waste data accessible and actionable for haulers, generators, regulators and processors. Gates is a Waste360 40 under 40 winner and holds a B.S. in Civil and Environmental Engineering from the University of Maryland.

Antonis Mavropoulos is the founder and CEO of D-Waste and the President of the International Solid Waste Association. He has been involved in solid waste management projects for 20 years, in 20 countries and he has completed more than 150 projects. He strongly believes that a Wasteless Future is realistic, by combining technical and social innovation. His recent research work deals with the Fourth Industrial Revolution and its impacts to waste management and recycling. Before that, his work has focused on Globalization, Megacities and Solid Waste Management as well as with on the use of mobile apps for a better waste management. He is also the inventor of Waste Atlas, a global interactive map that is developed in cooperation with GIZ SWEEPNET, ISWA, WTERT, SWAPI and Leeds University. Antonis has published and participated in the writing of several books and scientific publications, while his articles have been translated in Portuguese, Rumanian, Hindu and Spanish. For more about him, visit his blog at http://wastelessfuture.com.

Antonis Mavropoulos is the founder and CEO of D-Waste and the President of the International Solid Waste Association. He has been involved in solid waste management projects for 20 years, in 20 countries and he has completed more than 150 projects. He strongly believes that a Wasteless Future is realistic, by combining technical and social innovation. His recent research work deals with the Fourth Industrial Revolution and its impacts to waste management and recycling. Before that, his work has focused on Globalization, Megacities and Solid Waste Management as well as with on the use of mobile apps for a better waste management. He is also the inventor of Waste Atlas, a global interactive map that is developed in cooperation with GIZ SWEEPNET, ISWA, WTERT, SWAPI and Leeds University. Antonis has published and participated in the writing of several books and scientific publications, while his articles have been translated in Portuguese, Rumanian, Hindu and Spanish. For more about him, visit his blog at http://wastelessfuture.com.

Dr. Vivek Agrawal specializes in Solid Waste Management, Communication and Urban Health. His major contributions in the field of solid waste management includes: concept of microplanning in waste management, ICT in MSWM, Initiated Surplus Food Collection System and community-based waste collection systems involving microentrepreneurs. He is currently an Advisor, at Kanak Resources Management Ltd. Previously, he was a Managing Director at KRML, a company that specialized in the collection and transportation of municipal solid waste projects in Nagpur, Vadodara, Jodhpur and Gwalior. He has also been the Managing Director of Greentech Infra Pvt Ltd, a company working on facilities management, green building development, infrastructure and waste management projects in Rajasthan, Maharashtra and Madhya Pradesh. Dr. Agrawal has been recognized by the UN Habitat Scroll of Honour Award 2004 on behalf of CDC, led CDC to get selected for Best Practices in Urban sector by UN Habitat in 2007 and 2010, reached the semi-finals of Schwab Social Entrepreneur of the Year Award, reached the finals of Sankalp Awards in 2010, was featured in the Forbes blog in 2013 and gave a global Interview on the D-Waste Web site in 2013. He can be reached at [email protected].

Dr. Vivek Agrawal specializes in Solid Waste Management, Communication and Urban Health. His major contributions in the field of solid waste management includes: concept of microplanning in waste management, ICT in MSWM, Initiated Surplus Food Collection System and community-based waste collection systems involving microentrepreneurs. He is currently an Advisor, at Kanak Resources Management Ltd. Previously, he was a Managing Director at KRML, a company that specialized in the collection and transportation of municipal solid waste projects in Nagpur, Vadodara, Jodhpur and Gwalior. He has also been the Managing Director of Greentech Infra Pvt Ltd, a company working on facilities management, green building development, infrastructure and waste management projects in Rajasthan, Maharashtra and Madhya Pradesh. Dr. Agrawal has been recognized by the UN Habitat Scroll of Honour Award 2004 on behalf of CDC, led CDC to get selected for Best Practices in Urban sector by UN Habitat in 2007 and 2010, reached the semi-finals of Schwab Social Entrepreneur of the Year Award, reached the finals of Sankalp Awards in 2010, was featured in the Forbes blog in 2013 and gave a global Interview on the D-Waste Web site in 2013. He can be reached at [email protected].