Transfer trailers are an efficient tool to move waste material and recyclables to distant disposal sites and recycling facilities. Over the road transportation of waste and recyclables requires special care for safe operations.

By Will Flower

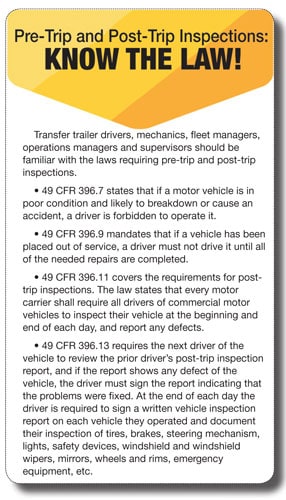

Transfer trailers are routinely used to ship 20-ton loads of MSW to distant disposal sites. Like other commercial vehicles, tractor-trailers are subject to a number of DOT regulations including the Federal Motor Vehicle Carrier Safety Act, which requires commercial drivers to inspect vehicles at the beginning and end of each day in an effort to make sure trucks are safe to operate. A thorough inspection of the vehicle is fairly simple and takes 10 to 15 minutes to complete. Importantly, drivers should be properly trained and instructed on the pre-trip and post-trip inspection process including the requirements for paperwork to document the condition of vehicle.

Different companies may have different processes for conducting pre-trip and post-trip inspections. However, in all cases, the driver must be familiar with the mechanical components and operation of the vehicle. A checklist is a useful tool to aid the driver in conducting an inspection without forgetting anything. Skipping any items during the inspection process will only increase the chances of an accident or breakdown. Done correctly, pre-trip and post trip inspections will comply with the law and give the driver confidence that the truck is safe for the work ahead.

Safety at the Transfer Station

Drivers of tractor-trailers need to take precautions at transfer stations, as their vehicles are longer and make wide turns that can make it tricky to get on and off a scale. Once positioned for loading, the driver should stay with his or her trailer while it is being loaded. If the driver needs to exit the cab of the truck, he or she should first look around to get the lay of the land and recognize any potentially hazardous situations. A quick scan of the tip floor or loading area may mean the difference between a safe day and an unexpected incident. Drivers should always use proper Personal Protective Equipment (PPE) including a high visibility safety vest, hardhat, gloves and eye protection.

The driver should be alert at all times especially for other vehicles that may be entering or exiting the transfer station. Drivers must also be careful when walking around their vehicles as tip floors and loading areas can be cluttered with waste, slippery and uneven.

Once the trailer is loaded to the proper weight, the load will need to be covered. During the tarping process, the driver will need to take precautions, as falls are dangerous to workers who work on elevated platforms and on top of trucks and trailers. Some transfer stations and landfills have tarping stations that allows drivers to safely tarp and un-tarp loads. Most tarping stations provide a level surface for workers to stand with adequate guardrails to keep employees safe while a tarp is being placed on or removed from a trailer. It is important to keep tarping stations clear of ice and snow during the winter months. Additionally, tarping stations should have adequate lights to allow drivers to have good visibility.

If the transfer station does not have a tarping station, the driver may need to climb on the trailer to cover the load. In these cases, the driver must have proper training and use fall protection to minimize the risk of a fall. Many slips and trips that result in falls can be traced back to three root causes:

1. Improper footwear: Good quality work-type safety shoes with slip-resistant soles and heels will help keep employees safe. Good footwear is especially important in transfer stations, landfills and recycling centers where the walking surface may be slippery.

2. Inattention: The best defense against tripping and slipping is to be alert. Drivers need to watch where they are walking and stay alert to their surroundings.

3. Not practicing “three points” of contact: Drivers should be reminded of the “three points” of contact rule—always have two feet and at least one hand or both hands and at least one foot in contact with a vehicle or structure.

Safety Over the Road

The load that is being carried, along with road and weather conditions, can dramatically alter the handling, stability, steering, braking and acceleration of a tractor-trailer. Drivers can eliminate rollover accidents if they take these precautions:

• Pay attention to surface conditions. Soft surfaces and un-level surfaces may potentially cause a rollover.

• Be alert for road shoulder conditions. Soft shoulders or no shoulders may cause a truck to tip and possibly roll or flip.

• Check tires and maintain correct tire pressure.

• Be aware of the truck’s center of gravity and realize that it changes depending on the load in the trailer.

• Make sure the load is stable and secure.

• Slow down before entering curves and on highway exit and entrance ramps. Remember, posted speed limits are for cars. Tractor-trailer drivers should take extra precautions and slowly execute turns.

When making a turn:

- Look ahead and plan the turn.

- Pick a proper entry point for the turn.

- Slow down before the turn and brake smoothly in a straight line when approaching the corner.

- Steer smoothly out of the turn.

- Step on the throttle to gently accelerate out of the corner.

Many rollover accidents occur because the driver of the transfer trailer is traveling too fast and fails to properly negotiate a curve or turn resulting in the truck leaving the roadway. During safety training, remind drivers to slow down around curves, and that the posted speed limits for curves are meant for automobiles, not tractor-trailers with 20-ton loads.

Safety When Unloading

Safety When Unloading

Another risk of an accident occurs when the trailer is being unloaded especially with trailers that unload by raising one end of the trailer and waiting for the material to slide out the back end. Unloading a transfer trailer will raise the center of gravity resulting in less stability. Stuck loads or frozen loads that will not slide out of the trailer or container can increase the risk of rollover.

At the landfill, the driver must position the trailer on level ground as even a slight slope can increase the chance of a rollover. The driver must make certain that the tailgate is unlocked before the unloading process begins. The stability of the surface is another important consideration. A mushy or soft surface may result in the truck tipping especially as the weight of the load is transferred to the rear wheels during the unloading process. High winds can be a problem especially at a landfill when tip trailers are raised in the air during the unloading process.

If a truck or trailer does roll, the driver and everyone around the vehicle is in danger. For this reason, drivers should maintain a safe space between vehicles. Equipment operators including compactor and dozer operators need to be especially careful when working around trucks and trailers that are unloading.

Other Safety Concerns

A number of other safety concerns can be reviewed with drivers of transfer trailers. Getting sufficient rest is critical as driver fatigue is a contributing factor in many accidents involving over-the-road vehicles. Drivers should always obey size and weight limits and posted speed limits. Avoiding distractions especially texting is another critical safety rule. As the saying goes, “it can wait.” Finally, drivers should never jump from the truck or trailer. While these may seem like obvious precautions, the reality is that countless injuries occur each year because basic safety rules are not followed. Taking precautions and exercising good judgement will help keep tractor-trailers safely rolling down the highway. | WA

Next month’s Safety Brief will focus on using social media to promote safety.

Will Flower is the Vice President of Corporate and Public Affairs at Winters Bros. Waste Systems. Will has 36 years of experience in the area of solid waste management and environmental protection. He has held operational and executive leadership positions at the Director’s Office of the Illinois Environmental Protection Agency, Waste Management, Inc., Republic Services. Inc. and Green Stream Recycling.

Share your safety tip. Submit your suggestions to Will Flower at [email protected].