Learn how to select the right roll-off container for your business.

By Meagan Daugherty

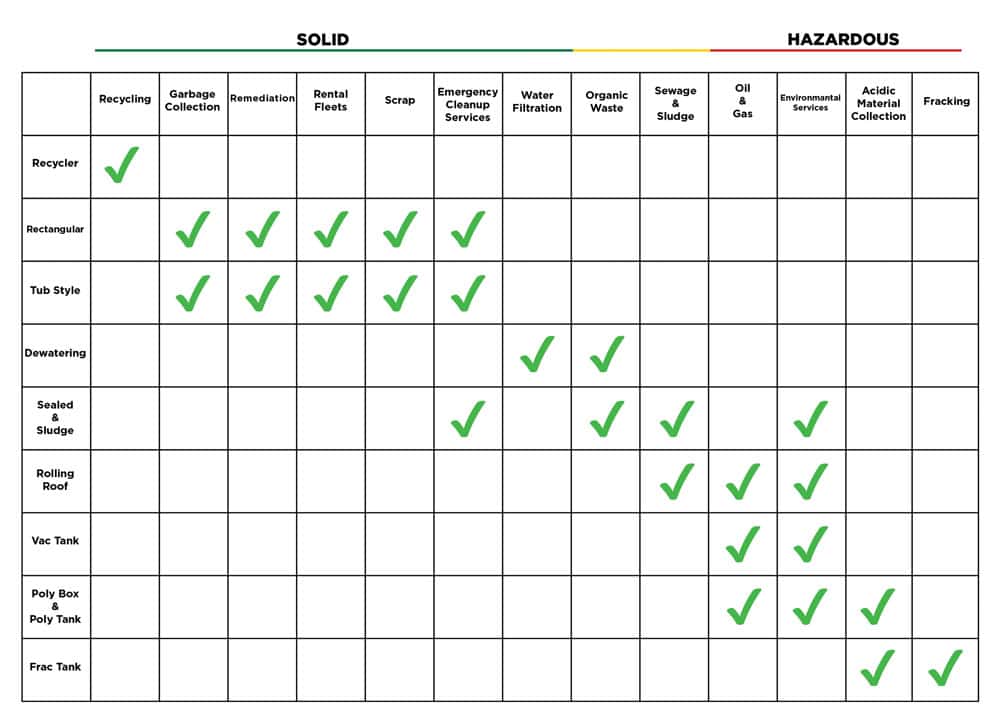

Hauling waste is a business. From what equipment to buy to which accounting software to use, we want it to be as efficient and profitable as possible. So, in a world of giant garbage cans, how important is the style and design of the container being used to haul the waste? Critical. Using the right container for the right application makes the job easier and safer and can extend the overall life of the container. How is this possible? It is simple. If you use the container for its intended purpose, along with routine maintenance, it will not wear prematurely because of improper use. For instance, hauling overly dense or caustic materials in a light duty, unlined container will drastically shorten the container’s useful life. Let’s talk about the 10 types of roll-off containers and how they can be best used in the field.

Hauling Solid Waste

Solid waste does not necessarily mean solid material, but rather anything that can be discarded without causing harm to human health and the environment. The following containers are typically used to haul non-toxic waste, such as garbage, debris, scrap, ocean/lake water and recyclable materials.

Rectangular Roll-Off Container

Rectangular containers can be found in different sizes and grades to best fit the hauler’s needs. The three grades of a rectangular container are light, medium and heavy-duty, and are available in a variety of hook-up styles. A tarp can be added to this style of container to keep materials in the container and water and other contaminants out. Rectangular style containers are versatile and can be used in a variety of different industries. It is important to use the proper grade of container for the correct job in order to avoid damage and/or injury. Misuse is a large cause to container damage. An example of this would be using a light duty container for a heavy-duty scrap yard. A light duty container is ideal for garbage collection, light-weight construction and demolition debris, and other light duty jobs, such as recyclable materials. A medium-duty container is popular in the construction and demolition industries. This middle grade container is also used in the roll-off rental fleets for both residential and commercial jobs. Heavy-duty scrap yards and collections will need to use a heavy-duty roll-off to maintain the longevity of the container.

Tub Style Container

The tub style container is similar to the rectangular style roll-offs when it comes to the manufacturing specifications. The major differences that are noticed in tubs are their tapered sides for ease of dumping and smooth sides for advertising decals. A tub is used in a variety of industries ranging from recycling to heavy duty scrap, following the same light, medium and heavy-duty guidelines as the rectangular to avoid damage and/or injury.

Images courtesy of Deist Industries.

Sealed and Sludge Container

Found in both rectangular or tub style design, the sealed and sludge style containers are built with the same specifications. A standard sealed container is compared to the specifications as a standard roll-off, while the sludge container is more for heavy-duty and dense applications. The main difference is seen with the added feature of a sealed tailgate. A sealed tailgate is manufactured with a track and seal coupled with slider style hinges to secure the seal tight to the container. This gives security to its users, ensuring that almost all materials will stay in the container while being stored or transported. Because of this, sealed and sludge containers are gaining popularity. They can be seen in similar industries as the rectangular and tub style containers, but for more secure hauling.

Dewatering Container

Used to separate solids and liquids, the dewatering container creates a one step process that then drains the liquids from the container. This allows for a decrease in the container payload and saves users money at landfills. Dewatering containers are manufactured with either a removable or permanent perforated steel basket that allows the separation process to occur. They also feature a sealed tailgate and apertures for drainage. While most users will use this roll-off to drain out the liquids from sludge, grease trap waste, septic waste and similar applications, dewatering containers have also been used to separate the unnecessary solids from drinking water, ocean water and other filtration and cleanout processes.

Recycler

Although the recycler is not as common in the waste hauling industry, the increase of environmental laws may increase its use. Recyclers are often built to custom specifications. Different options available are peak, hip/gambrel, or flat roof, hinged or sliding lids, interior dividers and more. With these options, a recycler can be used for a wide range of materials, such as clothing, batteries, plastics, cardboard and glass.

Image courtesy of Yossi’s Carting & Rubbish Removal, LLC.

Hauling Hazardous Waste

Hazardous waste is solid and liquid materials that can be harmful to the human health and the environment. Characteristics that define a hazardous material is flammability, corrosivity, reactivity and toxicity. The following containers are typically used to haul waste (both hazardous and not) that must be completely contained and inaccessible during storage and transport.

Sealed and Sludge Container

Although used strongly within the solid waste hauling industries, both the sealed and sludge roll-off containers can also be used for some hazardous waste applications. With the help of an added tarp system, both the sealed and sludge containers can transport septic waste, sludge and other similar applications to and from jobsites with less chance of leakage, spillage and fly outs.

Rolling Roof

A rolling roof container, sometimes known as a clamshell container, has a sealed tailgate and sealed lid(s) to transport and store hazardous waste materials. Rolling roofs can be manufactured with a single or double rolling lid. The roof is used to keep the hazardous chemicals and liquids from escaping the containers, as well as keeping foreign objects/materials such as rain and unwanted debris, from contaminating the contents. This can be used in the environmental, oil and gas and emergency services, as well as soil testing, water testing and wetland restoration.

Vacuum Tank

A vacuum tank is a completely sealed and enclosed container used to transport hazardous and non-hazardous liquids and sludge materials to and from a jobsite. They can also be used for storing materials. Vacuum Tanks are manufactured to secure and contain materials that can be harmful if exposed. They are most likely found being used in the oil and gas industry for pipeline, well and environmental services.

Poly Box and Poly Tank

Poly boxes and poly tanks are specialty containers made with heavy duty plastic polymer that is resistant to corrosion, providing longevity to its use. The sealed tailgate ensures that all material will stay in the container. This roll-off is ideal for storing liquids that are too acidic to be stored in a steel container. With rounded corners, they provide easier cleanout between uses. This container is used for specialty applications such as storing and transporting acidic materials. They can also be used in the oil, gas and environmental industries.

Image courtesy of Entegra Energy Solutions.

Frac Tank

A Frac Tank is a completely enclosed roll-off container that is used for onsite storage and/or safe transportation of hazardous chemicals and liquids. Within the name, it is easy to see that Frac Tanks are commonly used in the fracking industry, however, they can also be used for liquid and/or solid waste storage and containment.

Invest in the Right Style

We know that you have a large amount of business decisions that need your attention. Now that you know the 10 types of waste hauling containers and how they are used in the field, one of them can be made a little simpler. You can now invest in the right style and design of your hauling equipment. If you continue to use and properly maintain the containers, you will be able to run your business as efficiently and profitably as you can. | WA

Meagan Daugherty is the Communications Specialist for Deist Industries, Inc (Hadley, PA). She can be reached at (724) 253-5055 or e-mail at [email protected].

You may also like:

Efficiency that Goes to Waste: Choosing the Right Size of Roll-On Container for Refuse Hauling

Containers/Carts: Choosing the Right Bins for Your Recycling Program