As a self-sustaining facility, the Material Recovery and Energy Plant in Salem County, NJ will be the first one in this country and of this size. It will prove a first-in-class Waste-to-Energy “Plus” facility that promises “zero-to-landfill” capability, environmentally responsible odor and emission-control, and economic and social development for the surrounding community.

For the past seven years, METT USA, led by CEO Mark Gay, has been working in support of Castlepines Global Equity Group to establish a Materials Recovery and Energy Plant (MERP) in North America. MREP will prove a first-in-class Waste-to-Energy (WTE) “Plus” facility that promises “zero-to-landfill” capability; environmentally responsible odor and emission-control (well beneath EPA standards); economic and social development for the surrounding community; and >200 MW of reliable 24/7 green-energy off-take for 50 years. China, Dubai, Mexico City and Ethiopia have undertaken similar projects and the plan is to have MREP USA surpass each of those initiatives.

For the past seven years, METT USA, led by CEO Mark Gay, has been working in support of Castlepines Global Equity Group to establish a Materials Recovery and Energy Plant (MERP) in North America. MREP will prove a first-in-class Waste-to-Energy (WTE) “Plus” facility that promises “zero-to-landfill” capability; environmentally responsible odor and emission-control (well beneath EPA standards); economic and social development for the surrounding community; and >200 MW of reliable 24/7 green-energy off-take for 50 years. China, Dubai, Mexico City and Ethiopia have undertaken similar projects and the plan is to have MREP USA surpass each of those initiatives.

Scouting a Location

METT was developed by a group of experts from the United Kingdom, New Zealand, and Australia while they were working together on a project in the Middle East in 2005. In 2010, “METT Group” was being funded by the World Bank to build 50 smaller scale WTE facilities in Northwestern Egypt. METT reached out to Mark, who at the time was in the aviation consulting business. His job was to design and produce large payload airships to help deliver the waste from densely populated urban areas. After the “Arab Spring” when the Egyptian government changed hands, the business opportunity fell through; however, the idea was brought to the States in 2014.

Officials of METT had many high-level discussions with government and industry officials in both the U.S. and Mexico when looking for a location to build this type of facility where they would have access to the resources they needed, such as sizable tracts of land, substantial volumes of gray water, transportation and reliable supply of waste streams. Mark explained that they looked at a few other locations before finally determining that the old DuPont plant, now partially operated by The Chemours Corporation in Salem County, NJ, would solve the “Rubik’s Cube” difficulty of MREP. “We began by looking at Mexico. The waste stream was there, which would result in a high power off take rate, but we could not guarantee that the waste would be protected from pilferage of the recyclables and used tires before reaching the plant. We would be more likely get a lot of sludge that would not have generated the thermal value that we needed in the process. We also looked at southern Kentucky, but, unfortunately, the manpower to operate the plant was not available and the waste was going to have to come from out of state. We found that New Jersey was ideal because the proposed site had access to multiple four-lane highways, existing rail and barge access along the Delaware River. One hundred thousand tons of waste is presently transported daily within the Baltimore/Philadelphia/New York urban hub, so we would need to capture only 16 percent for processing at the Salem County location. It was also favorable because of New Jersey’s preference to go completely non-fossil by 2050—it all comes together there for us.”

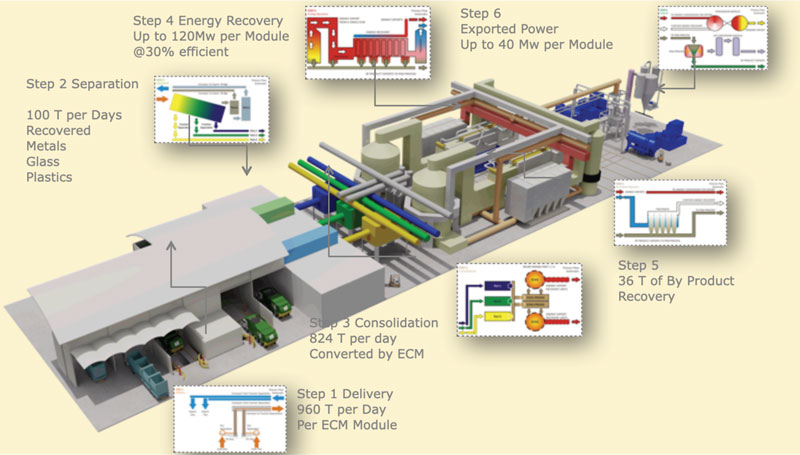

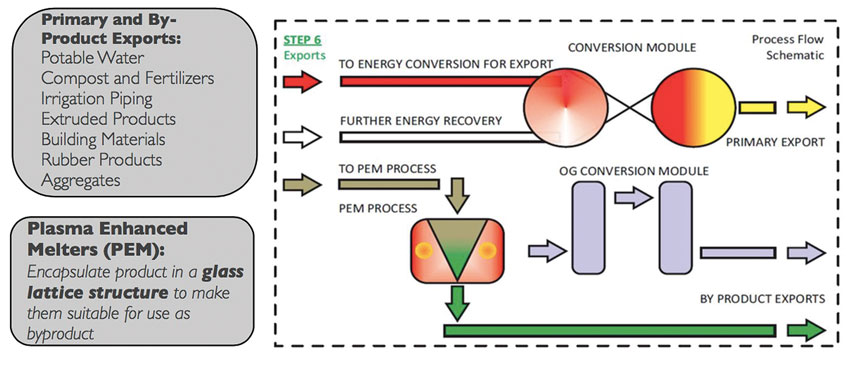

Finding the right location was a seven-year challenge because METT would need 2 million gallons of water per day—not necessarily potable water, but gray water. The good news is that the facility would be able to return 85 percent of that to agricultural quality and, if there is a market for it, make the water fully potable. That could prove to be a factor in Salem County because they are dealing with the problem of rising salination levels in their aquifers—which can be addressed over time. Another initial set of requirements is the need to be able to get a long-term waste stream contract for at least 1 1/2 million tons of waste per year; then, develop a long-term power off take agreement of at least 10 years with rates that support the build out. Once the plant is up and commercially operational, other “products”—active carbon,

fertilizers, etc.—will generate up to 55 percent of the revenue.

METT is in detailed negotiations to lease approximately 230 acres and to purchase an additional 760 acres from The Chemours Corporation along the Delaware. The site is currently serviced by Conrail and has a standing 400-car rail yard. That Salem County location will simplify the challenges of waste stream delivery to the MREP facility and help to ensure that an equitable power-purchase agreement for MREP’s green energy can be achieved. Chemours and DuPont spent the last two years demolishing many of the buildings and taking them down to foundation level, so METT will essentially be building on lands that have previously been cleared. Says Mark, “The electricity revenue source is critically important to MREP’s financial model in the early years as we establish our recoverable metals/recyclable products market, and as the U.S. energy markets evolve to value MREP’s 4 to 6 million annual carbon-offset credits fairly. Longer term, we project that MREP’s ‘ancillary products’—potable water, active carbon, mercury, and polyurethane, repurposed plastics and reclaimed metals, fertilizer and other commodities—will generate more than 55 percent of annual revenues.”

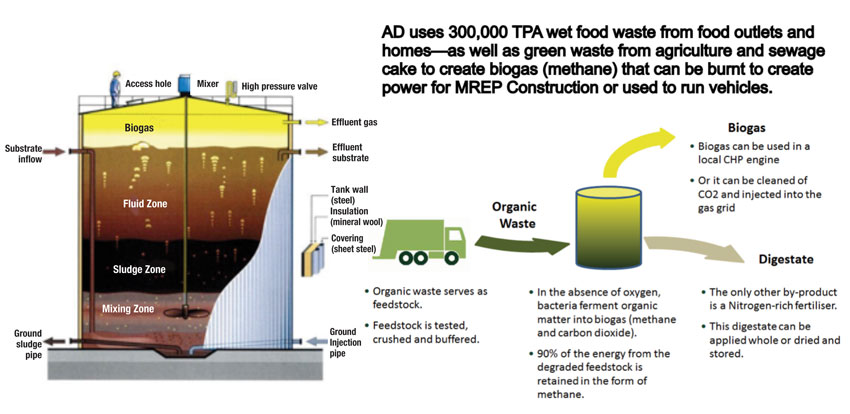

Reliable and continuous waste stream sourcing is a critical linchpin for plant design and a cornerstone for financial accreditation. METT’s analysis and preliminary design suggest a four-year ramp from 800 tons/day of food/biomass waste (to support Anaerobic Digestion) to as much as 11,000 tons/day of predominantly mixed/household waste (for a minimum 15 years with 25 years preferred) when full MREP build-out has occurred. This is one of the many challenges that METT will be handling during this process. “We are aware that comprises a substantial volume of waste and recognize fully the difficulties of coordinating contractual obligations four to five years in advance,” says Mark.

Waste Transportation

MREP Salem will have highway, barge and rail access. Central Penn Rail Service has assumed the role of developing and managing the waste streams for this facility. In addition, Central Penn will play a significant role in designing the transportation processes for all modes within the MREP as well as providing drayage services, railcar switching and other in-plant transportation services when the plant begins operation. “Our interim plan is to work with both CSX and Norfolk Southern for delivery of waste containers to capture the waste at transfer stations or in trucks where it would be transported a distance to a rail re-load. Our serving rail carrier is Conrail which is jointly owned by CSX and NS. Therefore, we have equal access to both the major eastern Class 1 rail carriers, which gives us greater flexibility in sourcing waste streams. The waste containers and rail cars would most likely be privately owned/leased by Central Penn and/or waste shippers,” explains Eric Bickleman, Owner of Central Penn Rail Service. “We have had conversations with people in Philadelphia, PA and their surrounding counties to bring waste by truck because they have short-term hauler contracts for their waste and it would be a short haul.” For pickup and delivery of waste from the Philadelphia and south Jersey regions, METT is proposing to use electric powered trucks charged by the electricity produced at the MREP facility. Essentially, short range waste hauling vehicles would be powered by the very waste they are hauling. “In addition to powering our own vehicles with that, there is a revenue source with the highways right here and we could provide a commercial charging station, which would lead to additional revenue for the plant and being much more green.” Mark also believes that MREP’s green energy for rapidly expanding warehouse facilities in Salem County and also for EV charging—both for transportation needs and as a commercial revenue stream serving the warehouse distribution network—will make MREP a successful proposition.

Commitment to 200 MW limit for electricity export makes >60% of MREP’s waste stream available for functional processing of secondary products.

For a longer waste haul, transportation rail will be the preferred mode due to its many inherent benefits, including lower costs along with reduced emissions and truck traffic on regional highways. “We are currently strategizing plans with New York City. We would definitely love to get material from there, but the city has long-term waste contracts. We are the new kid on the block here in the waste business, so we are reaching out to established waste haulers. In addition, New York has a well-established waste-by-rail infrastructure, and we see the Salem MREP as a logical destination as available landfill space decreases. Other large east coast cities do not have established rail served infrastructure. In this case we are proposing a logistics process based on the use of standard intermodal waste containers moved by truck from existing municipal transfer stations to a rail transload site where they would continue on double stacked rail cars to MREP. We have had preliminary discussions with both CSX and Norfolk Southern on this process and they are receptive to this line of business,” says Bickleman.

Permitting and Politics

As with any “first-off” project, many lessons have been learned about local politics and the difficulty of changing business and regulatory culture. Mark has begun working with NAES Corporation and ESRA Consulting to begin the permitting process for the facility. Because there are a lot of pieces to this project, Charles Hassler, who has been working on economic development within Salem County, stepped in to get Mark connected with the right contacts and people who needed to be involved in the process. “The county is always looking for more economic development and this project is a great investment with great job opportunities, including above-market manufacturing, engineering, executive, fuel technicians, etc. When I first met Mark, he pitched the idea to me and I thought it was a great one, so I do what can to help facilitate meetings with the mayor as well as local and state legislators. They want to do it all the right way. When the time comes, we will have public meetings to show everyone the facility’s overall plan and I will be there to support them every step of the way.”

Charlie introduced Mark to Doctor Michael Gorman, who is the President of the local Salem Community College and he loves the program. In fact, the college as well as the local vocational school and high school are interested in developing programs that will fit into training a workforce for this facility. Mark says, “We have a way for people to get into a good job and this is an ideal opportunity. When the time comes, we will go out to the public and talk with everyone. From the start, we engaged with local public officials, primarily at the Salem County level and then later with the local council of Pennsville to the local Congressional office. Then, we moved to state government and the New Jersey Business Development authorities at Trenton. We haven’t had the town hall meetings just yet, but we look forward to those because we think it is a great way to get some feedback, given the history of the property.”

The project enjoys strong political support from all levels of the state and Salem County government. Charlie also introduced Mark to the New Jersey Economic Development Authority, and they are allowing METT to compete for a large redevelopment loan for the brownfield property that the facility is being built on. Mark points out that they will also need an Air and Water Quality Permit. “We have been working with New Jersey Department of Environmental Protection, Compliance and Enforcement, and those discussions will take place shortly. They have asked us to walk them through the technologies that we intend to use. We did pre-flight all of this two years ago with the former head of the department. We are confident that we will get the environmental permitting head nod early on.”

A Promising Future

While METT has a conditional letter of funding from Castlepines on reasonable terms, they are a public pension fund, and they want their investment guaranteed. Mark comments that they are currently completing an application to the New Jersey Economic Development Program for up to $5 million dollars in development funds. Simultaneously, Eric is working to secure letters of intent from waste stream providers. “No one is going to deal with a contract until the plant is fully operating and attested. But what investors are telling us is to show them letters of intent from investment grade municipalities and/or private haulers. METT USA has already drafted and reached initial agreement with Chemours on a 25-year lease and purchase of the site, and drafted site agreements for water offtake, security, and all the other pre-requisites at the site. We need to take next steps with the political dialogue and the power offtake agreement and engage with the Regional Greenhouse Gas Initiative (RGGI) program because we will have a lot of carbon offset credits for which we are eligible. If we can’t find someone there locally for an energy offtake or a large municipal buyer, we will compete in NJ’s annual auction for wholesale clean energy,” says Mark. With a plan to begin building in Spring 2023, it is going to take four years to get to full commercial operations; then, in 2028 the plant will be generating at full capacity. METT’s intent is to build two anaerobic digestors with 10 Megawatts offtake capability apiece, so that they have some gas initially to get a foothold. Then, they will use the gas from the second anaerobic digestor to power the first plant, so that they are totally self-sufficient. They are also planning on implementing solar panels on the rooftops.

As a self-sustaining facility, MREP Salem will be the first one in this country and of this size. It will be great for other businesses, and Mark is confident that MREP has a promising future in North America. “Salem County has been a real blessing throughout this whole process. We plan to have MREP Salem operate to high standards and achieve long-term performance.” | WA

For more information on METT USA, the MREP construction and operation, contact Mark Gay at [email protected].

For more information on Central Penn Rail Service, the waste stream development and logistics, contact Eric Bickleman at [email protected].