The fate of recyclable materials rests in the hands of a broad set of stakeholders who must all do something new and different to support a transition to a circular economy. Strong, coordinated action is needed in areas ranging from package design, capital investments, scaled adoption of best management practices, policy interventions, and consumer engagement.

By Professor Edward Kosior

The unanimous agreement by U.N. member states to develop a legally binding treaty to end plastic pollution is a significant step forward. The U.N. Environment Assembly (UNEA 5.2) has recognized the need to give governments the flexibility to identify binding and voluntary measures given there is no single approach to solving this global challenge.

Certainly, to date our global, disparate initiatives are falling woefully short. We need to level out the playing field. Lower-income countries will struggle to meet global targets without significant support in the form of capital for waste management and material recovery. Yet, it is not just the lower-income countries that are struggling with their targets. Most countries around the world have a lot of work to do to redress the balance, starting with the U.S.

According to a report by Science Advances in 2016, the U.S. generated the largest amount of plastic waste of any country in the world, 42 million metric tons (42.0 Mt). Between 0.14 and 0.41 Mt of this waste was illegally dumped in the U.S., and 0.15 to 0.99 Mt was inadequately managed in countries that imported materials originally collected in the U.S. for recycling. The report goes on to show that the amount of plastic waste generated in the U.S. and estimated to enter the coastal environment in 2016, was up to five times larger than that estimated for 2010.

Waste’s Role in Climate Race

The direct impact of waste management sits at the heart of climate change. Global waste currently generates more than 1.3 billion tons of CO2e. More than half of possible CO2e savings from waste will come from increased recycling rates and increased recycled content of all material in the recycling stream.

In fact, it has been estimated that by significantly improving waste collection, sorting, and recycling we can reduce global GHG emissions by between 2.1 to 2.8 billion tons of CO2e per year compared with ‘business as usual’.

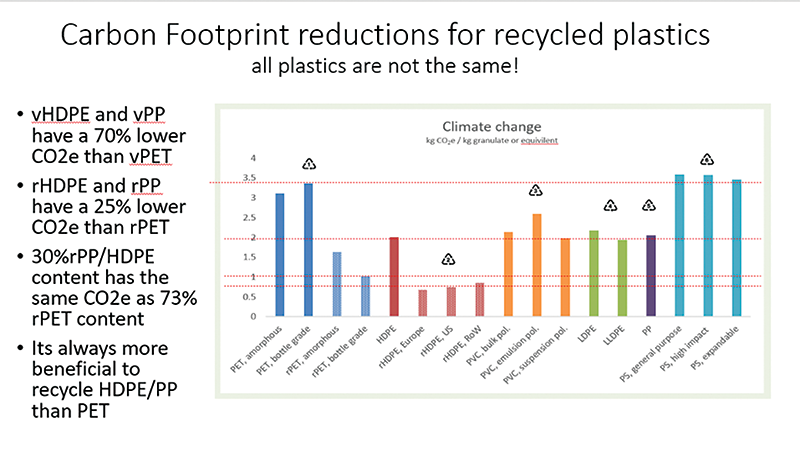

CO2e Vary from Plastic to Plastic

While the above is a clear reminder that everything we put into production should be designed to either be recycled or reused, we also need to take into account that not all recycled plastic actually has an equal carbon footprint. This little-known fact potentially has a huge impact on the way we should view recycling.

Take polypropylene (PP), for example. This is a versatile polymer used in many products we use daily—from delicatessen tubs and beverage caps to yogurt cups and trays for meat, fish, and fruits. In fact, PP accounts for around 20 percent of the world’s plastic.

Invisible Polypropylene

According to The Recycling Partnership’s 2020 State of Curbside Recycling, PP is not broken out as a separate polymer in the U.S. To date, it has largely been collected in curbside programs and sorted in MRFs. Many MRFs have specific polymer sorting capacity focused on PET and HDPE because these polymers are in higher demand in the market. They are also more readily recognized mainly as bottles and are presumably available in higher quantities than PP (pots, tubs, and trays) in the household stream.

Yet this same report suggests there may be as much as 17 pounds of PP available per year from a single-family household. This would place PP at higher generation rates than both natural and colored HDPE with total annual PP tonnage generated by U.S. single-family households estimated at 827,000 tons.

Despite this data, a lack of infrastructure to collect and recycle PP in the U.S. means this valuable material is on the verge of being

removed from use across the 50 states. The hard facts are that collection and recycling rates for all plastics in the U.S. are dropping—PET is down from 30 percent a few years ago to 27 percent. Ironically, recyclers are running short on materials.

In the case of PP, which is barely being recovered, it is a significant missed opportunity. Recovering PP could offer increased economic benefit and jobs, as well as reduce climate impacts, with the latter

being one of the most pressing reasons to re-address PP.

Analyzing Plastics’ Carbon Footprints

A recent lifecycle assessment by Plastics Europe that compares the carbon footprint of a range of different recycled plastics shows that recycled HDPE (such as milk bottles) and recycled PP (such as most of our pots, tubs, and trays that contain our food) have a 25 percent lower carbon footprint than recycled PET. What this tells us is that 30 percent recycled content PP or HDPE plastic has the same carbon footprint as 73 percent recycled content PET.

As such, this study clearly demonstrates that recycled PP or recycled HDPE is more environmentally beneficial than recycled PET and neither polymer should be ignored. This finding should play a fundamental role in re-shaping the way we manage different polymers, given that all of our future decisions relating to plastics and recycling should be driven by CO2 emissions.

Pros and Cons of PP

PP plays a valuable role in protecting and storing food. It is most often used for single-serve containers such as soup pots, ice cream tubs, and takeaway food containers. On top of being one of the FDA approved food contact materials, it is microwave safe and nonvolatile, which means it will not react with any type of food it stores whether it is acidic, basic, or liquid.

The downside of food-grade PP is that, until recently, we have been unable to produce food-grade recycled polypropylene (FGrPP), which has meant all PP food packaging is only made from virgin plastics.

These complexities are not unique to the U.S., but a large, global challenge that has, in part, been driven by industry’s focus on recycling PET drink bottles and single-use plastics such as bags and straws.

There has been little mention of the wide use of the pots, tubs, and trays that are placed in the recycling boxes, yet not generally recovered for specific recycling. PP is rarely used to make bottles and is missing from the recycling stream. Additionally, the complications of recycling PP for reuse in food-grade packaging have traditionally limited the economics of recycling.

Breaking Through the Challenges

The good news is that we now have cutting-edge technologies to specifically sort and decontaminate PP to food-grade quality. It has taken nine years of extensive research to reach this point, however, a 43-strong multi-participant project is well underway to create a world-first, post-consumer FGrPP, which should be on the market within 18 months.1

Using high-speed precision sorting of packaging with invisible fluorescent markers, followed by a second and essential step to clean and decontaminate the PP packaging to standards compliant with food safety authorities, brings us closer to closing the loop on FGrPP. As such we now have an unparalleled opportunity to re-dress the balance and boost recycling of a polymer that not only has a relatively reduced carbon footprint, but that also plays a vital role in reducing food waste—yet another key factor in our race against global warming.

Pivoting our View of ‘Waste’

Minimizing our waste will only occur once we actively start unlocking the value in the materials we still think belong in a ‘waste’ stream. Realistically, we cannot eliminate plastic from the

supply chain, and even if we did, that would not solve the world’s climate crisis. Quite the contrary.

According to a Waste Reduction Model (WARM), if all the 37.4 million tons of single-family recyclables were put back to productive use instead of lost to disposal, it would reduce U.S. GHG emissions by 96 million metric tons of carbon dioxide equivalent. It would also conserve an annual energy equivalent of 154 million barrels of oil and achieve the equivalent of taking more than 20 million cars off the U.S. highways, not to mention generate an estimated 370.000 full-time equivalent jobs.

Closing Every Loop

What we need to do is efficiently close the loop on each different polymer; we need to expand our success story with PET to all polymers and stop taking a ‘one solution for all’ approach that sees us sweeping millions of tons of plastic resources into our oceans, and at the same time, removing a polymer from food packaging, that could help to reduce food loss and waste globally. UNEA 5.2 proposes to address the entire lifecycle of plastics from production to disposal and is certainly heading in the right direction to achieve this.

Ultimately, the fate of recyclable materials rests in the hands of a broad set of stakeholders who must all do something new and different to support a transition to a circular economy. Strong, coordinated action is needed in areas ranging from package design, capital investments, scaled adoption of best management practices, policy interventions, and consumer engagement. | WA

Professor Edward Kosior is founder of Nextek and NEXTLOOPP. Professor Kosior’s expertise in the plastics recycling sector spans 48 years, split between 23 years as an academic and 25 years working in plastic packaging recycling. He has been instrumental in designing numerous modern recycling plants and has achieved a number of patented recycling breakthroughs. He also provides support to organizations such as the Earth Champions Foundation, Plastics Oceans, PEW Foundation Trust on the Project “Stopping Ocean Plastics”, and is the founder of NEXTLOOPP, the multi-client project aimed at closing the loop on food-grade PP. For more information, visit www.nextek.org or www.nextloopp.com.

References

• www.science.org/doi/10.1126/sciadv.abd0288

• https://recyclingpartnership.org/stateofcurbside/

Note

1. NEXTLOOPP by Nextek