How could your business benefit from strategically using locks on waste carts? Explore the categories of available locks and find strategies to identify the best lock for your needs. Then, expand your understanding of the potential for integrating lid locks into service offerings.

By Justin Blazer

What happens to our waste as it sits in a bin awaiting collection? For some, nothing happens. Their garbage cans go week-after-week properly containing all waste as expected. For others, their bin is not so reliable. Whether their cart is subject to pests, wind, overflowing waste or bad actors, a plain unlocked bin does not always meet the modern clean standard. These less than perfect bins create the need for a garbage can “locking” mechanism.

Photos courtesy of Blazer Brand.

Garbage can locking mechanisms vary in form with each having its own purpose and specialization. Lid locks enhance the inherent utility of waste containers. Finding a lock comes down to identifying customer’s needs and assessing existing operational agility. Once you pick a lock, there are multiple ways your business can use locks to add value.

Part 1: Why Locks?

There was a marked decrease in the presence of litter when high-quality trash cans began to proliferate as a result of improved consumer supply chains along with waste haulers and cities purchasing cans for customers/residents. Placing waste into a container with a shut lid keeps communities cleaner. Today, litter from bins is not out of control, but bins do account for up to 10 percent of litter depending upon where they are located. The litter from containers alone could cost Americans hundreds of millions annually to clean up, not to mention the unquantifiable effect of litter that is not cleaned up.1

What does this mean for waste customers? Well, communities value being litter free. Residents and business owners value not having to clean up trash after a disease-ridden rodent rips through their bin. Neighbors value the aesthetic benefits of a closed lid. Waste collectors know this; they supply customers with garbage cans that get bigger and bigger in hopes of containing the weekly load. They do their best to clean up messes by equipping trucks with brooms and shovels for workers. Even then, cleaning up messes can take a long time and verges on being beyond the scope of work for a standard collection service. Knowing your way around common trash problems and providing preventative solutions for customers will enhance any business’ service offerings and environmental standing.

Part 2: Choosing the Right Lock

Every lock is designed to keep lids shut, but their similarities end there. When choosing the right lock for your bins, it helps to understand the different categories of locks available today. Then, consider three pertinent questions. First, will this solve the problem? Second, will this work on our customers carts? Finally, can we step up to the plate and integrate this into our collection process?

Types of Locks

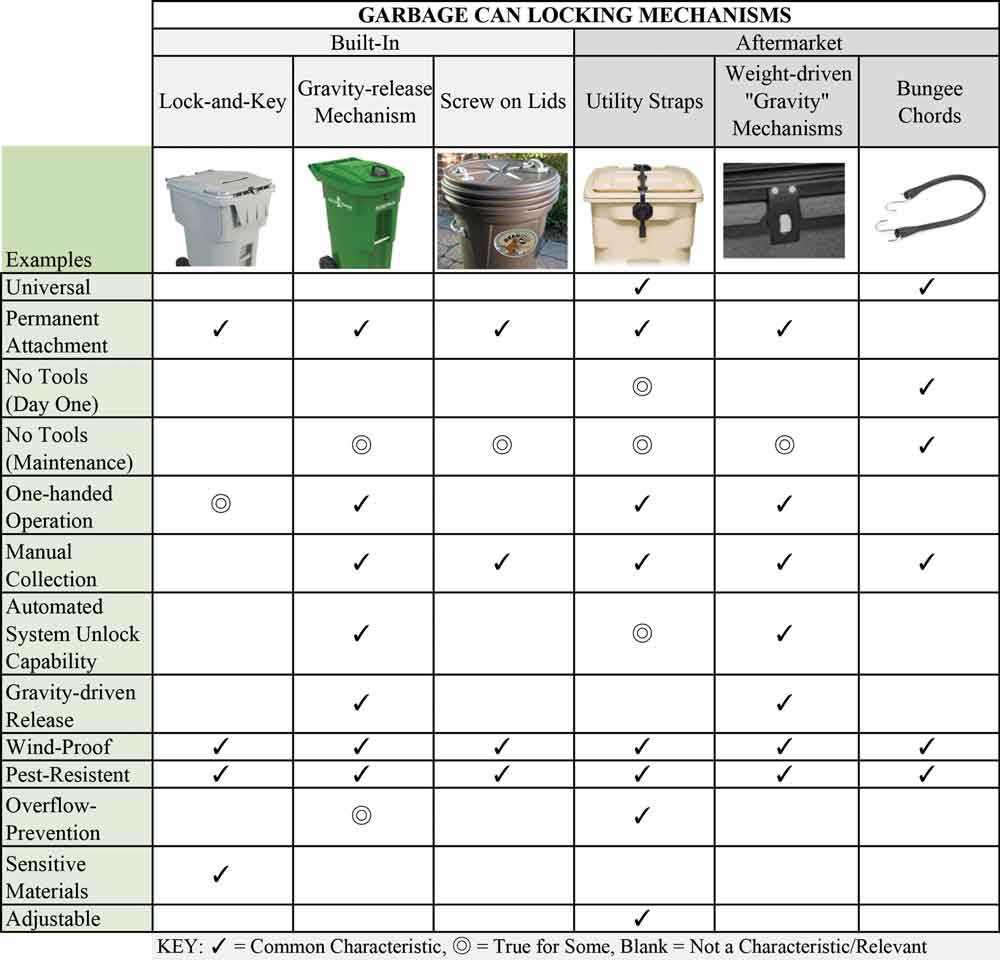

Use the chart below to get an idea of the various locks available for use today.

Images Sources (left to right): officesupplyhut.com, rehrigpacific.com, globalindustrial.com, blazerbrand.com, toter.com (2016), ULINE.com.

Will This Solve the Problem?

Effectiveness is a priority when choosing a lock. The problems your customers are facing should drive the decision-making process. Equip your customers with the right tools for the job. First, let’s point out one important distinction amongst locks—sensitive materials. Sensitive materials require a lock-and-key combination and preferably a metal-reinforced rim around the lid. Rarely will you find an aftermarket lock that can be added to a standard trash can and be reliable in service protecting sensitive materials. Also, note if your lock-and-key combo is gravity driven, then your materials will not be protected. To gain access, someone would just have to flip the bin upside down. Check out www.recycling.com/shred-bins for a summary of containers suited for sensitive materials.

Next, we have pests. What is the simplest way to prove the effectiveness of a potential lock against pests? Demo it. Provide high-value customers with a lock and then gather feedback. See if the lock you are looking into is effective at preventing pests in your area. Some locks are available direct-to-consumer and you can browse their ratings to get honest market-based feedback. For most pests, a customer-driven test should be sufficient. For bear problems, a variety of organizations certify equipment due the potential for human-bear conflict as a result of trash. Explore the Interagency Grizzly Bear Committee’s Certified Bear-Resistant Products by following the link in references.2

Another primary cause of litter in certain areas is wind. Wind problems are generally some of the easiest to address. Some locks list their wind strength rating, other locks will never be opened by a gust of wind. So, if your customers are dealing with wind problems, find them a lock that is easy to use, easy to install, long-lasting and effective. One special note for considering wind problems is how some locks are not effective when overflow is present.

Overflow is one of those problems most people are going to write off as human nature, an inevitable characteristic of trash. Overflowing cans are a problem; they create litter and they are an eyesore for communities. Not every lock will be capable of addressing overflow. Some complex mechanisms can get clogged by bags/trash as a bin reaches capacity. On the contrary, utility straps work best against overflow.

Will This Work on the Carts in Service?

As shown in the chart, locks come in two forms, built-in and aftermarket. Built-in locks are part of a can from day one and aftermarket locks can be added to existing cans. For built-in locks, this section is irrelevant. If you are looking to add locks as an aftermarket feature, then making sure the lock works on a large percentage of cans will allow you the freedom to make locks work for your business.

First, do you own your customer’s cans? If so, testing is simple. Buy the lock, then install it on the different models you supply to customers. The more universal, the better. Why? Because managing one model of a lock that is widely distributable to all of your existing customers is easier than having to go through the complicated process of making sure the right lock is delivered to the right customer with the right can. If you do not own your customer’s cans, you will need to find a universal solution to meet the needs of their diverse can lineup. Again, universal locks make operations simpler. It is just one and done.

Will This Work for Our Business?

When integrating locks into operations it is important to analyze the installation process and see if your customers can do it on their own. If they cannot, then find out if there are methods for making a large-scale installation project efficient. The same analysis should be applied to maintenance. Can the customer fix their lock, or do we need to send a worker?

Finally, the all-important question of collection integration. For manual collectors or multi-person crews, most locks add no time. Survey your employees to see what they think of popping open the locks. For automated collectors, locks are commonly taboo. Yet, challenge traditional thinking and consider the percentage of customers that will actually need/purchase a lid lock (hint: it is not everyone). Then, think about how management can train speed into the unlock process. For automated collectors with a driver seated on the left-side of the vehicle, speed is almost impossible without an auto-unlocking mechanism. If a driver is located on the right-side of the vehicle, speed may be possible. Some companies are even exploring mechanisms that attach to trucks and unlock latches, as opposed to the current and popular gravity-driven approach.

Part 3: Integrating Locks as Part of Your Business

The path to better bins via lid locks is laid out, now it is time to take action. Expand your thoughts on garbage can locks by exploring unique paths to using locks for business. Your business can experience financial rewards along with the added value of long-term customer retention as a result of the quality of service you are now able to provide:

• Make a lid lock complementary: Does customer service drive your business model? Can you afford to make your best customers even happier? Then offer them a lid lock free of charge.

• Free Reward to New Customers: “New Customers get a free lid lock designed to stop (insert local problem here) when they sign up for residential collection services.”

• Sell at Cost: Straightforward, purchase locks at wholesale prices and pass those savings onto your customers.

• Sell for a Profit: Garbage can lid locks can be a simple one-time addition to your services in exchange for a little extra cash.

• Sell for a Profit + Charge Installation Fee/Maintenance Fee: Grab onto some extra profit by charging your customers an installation fee on top of a discounted price for a cart lock. When their lock needs to be fixed, add on a maintenance fee.

• Keep as Assets and Rent them to Customers: There are some really durable locks on the market. Think about how long these could be a part of your business. Buy locks, keep them as assets (like your bins), and then rent them to customers.

The Future of Trash is Here

Hopefully, by now you see the potential for adding value to your organization through the selective use of lid locks on carts. The green, clean future of trash is here and preventing litter is a priority. Use locks as a way to get ahead of the competition by being the first to provide the right tools to meet your customers’ modern demands.

| WA

Justin Blazer is the Head of Product Development and Operations at Blazer Brand LLC (Pittsburgh, PA). He and his brother invented Blazer Brand’s first product, the Strong Strap, a garbage can utility strap (US Pat. No. 10,294,022). He leads Blazer Brand in developing innovative tools for clean, green and secure waste streams. Justin can be reached at (412) 252-2114 or e-mail [email protected]. For more information e-mail [email protected] or visit blazerbrand.com.

References

Mid Atlantic Solid Waste Consultants. (2009). 2008 National Visible Litter Survey and Litter Cost Study. [PDF File] Retrieved from: www.erplanning.com/uploads/KAB_2009_National_Litter_Study.pdf

Interagency Grizzly Bear Committee. (2019). Certified Bear-Resistant Products [PDF file]. Retrieved from: http://igbconline.org/wp-content/uploads/2019/12/191203_Certified_Products_List.pdf