Strategies/Planning

Carbon Offset Credit Hurdles for Municipal Solid Waste Projects

Municipalities interested in pursuing carbon offset credits in conjunction with the GCCS operation should thoroughly evaluate their current operation practices, along with staff capability to properly implement the Protocol requirements.

Cami Van Abel

Municipalities planning for solid waste carbon offset credit projects may think the biggest hurdles end with system construction. However, several factors, which may be expected or unexpected, can potentially throw obstacles up during the process of carbon offset credit verification. This hindrance can especially be problematic for projects with a planned revenue stream from carbon offset credits for construction capital paybacks and/or system upkeep and maintenance. This article describes hurdles that have occurred with recent municipal solid waste carbon offset credit projects, along with issues that typically come up during the project verification.

As of late, one of the biggest concerns with carbon offset credits are the voluntary market conditions and the role solid waste projects play in the market. Regulatory volatility, along with a saturation of landfill gas collection and control projects, have led to a decrease in the value of carbon offset credits from these types of projects. From an operational standpoint, site-specific conditions may not conform to sector-based performance standards and protocols. Being pro-active about checking current protocols and performance standards against project construction specifications (if applicable) or current site conditions will likely alleviate potential problems that could arise during project verification.

Another important aspect of municipal solid waste carbon offset projects is monitoring and data collection. Engineering consultants can provide vital technical guidance, but most likely municipality staff will perform the system monitoring and data collection. Strong oversight of the data collection procedures and monitoring results may be necessary in the beginning of the project to ensure the data is accurate and site specific.

Program Goals and Protocol Development

For the discussion of issues that may arise with the project verification, it is important to understand the goals of the carbon offset credit program your project will be registered and verified with. The Climate Action Reserve (Reserve), a highly regarded national carbon offsets program, is a common choice for potential carbon offset project developers. The Reserve’s core objective is to develop standardized approaches for industries to comply with in order to attain greenhouse gas (GHG) emission reductions. The principles the Reserve has developed in their approach to standardizing offset crediting include:

Determining the eligibility and additionality of projects using standard criteria

Quantifying the GHG emission reductions using standard baseline assumptions, emission factors and monitoring methodology

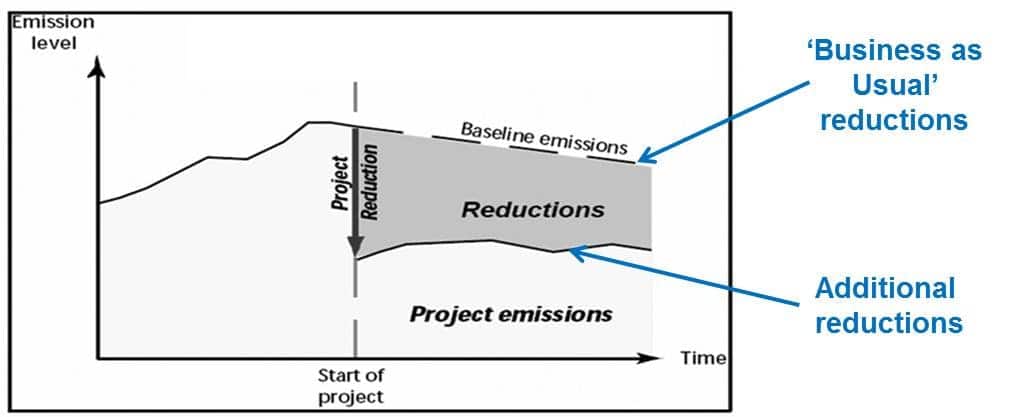

The concept of “additionality” is in an important one within the standardized protocol program of the Reserve. The reduction of GHG emissions associated with the project must be additional to what would normally occur. Therefore, not only are regulatory standards (i.e., whether the project is voluntary or required by a regulation) important, but also equally important are current common practice standards within the industry. Baseline emissions or “business as usual” emissions are developed and used to quantify the emission reductions achieved through the implementation of the project. This concept is depicted in Figure 1.

Therefore, in order for the project to be eligible to receive offset credit for GHG reductions through the Reserve, it must not be required by federal, State or local regulations, and it must meet a performance threshold that has been developed by the Reserve. The project standards are issued by the Reserve by sector-based protocols.

Landfill Project Protocol Compliance

Municipalities installing landfill gas collection and control systems (GCCS) with the intention of obtaining carbon offset credit revenue should review and be familiar with the Reserve Landfill Project Protocol (Protocol) prior to operation. Equipment standards, monitoring and calibration practices are described within the Protocol and may not readily conform to the capabilities and schedule of the staff responsible for the system operation and monitoring. It is important to keep in mind the goals and intent of the Reserve standardized protocol approach when developing the monitoring, record-keeping, calibration and maintenance manual for the site’s GCCS to ensure that the emission reductions are conservative, accurate, transparent and additional. A thorough review of the Protocol before the GCCS is installed will help municipalities obtain the most carbon offset credits they can if they comply with all aspects of the Protocol requirements. A discussion of the common issues that have resulted in a reduction in the amount of credits allotted to GCCS projects follows.

Record-keeping

To comply with the Reserve’s principles of crediting emission reductions that are real and verifiable, record-keeping of the GCCS monitoring and operation are very important. Without proper, tangible documentation, the Reserve will not be able to verify that the emission reductions have occurred. It is crucial for facilities to maintain monitoring records, equipment calibration certifications, GCCS operation records and equipment manuals to provide evidence that the GCCS has been managed in accordance with the Protocol. There are opportunities to deviate from the Protocol, with the Reserve’s approval, for record-keeping procedures, but they are reviewed on a case-by-case basis and may result in a discount factor being applied to the emission reduction credits for the period where the Protocol deviation occurred. In order for projects to obtain the maximum amount of emission reduction credits, it is important to understand and comply with the record-keeping procedures described in the Protocol.

Equipment Inspection and Calibration

The current version of the Protocol involves a more risk-based approach to ensuring that the monitoring equipment is calibrated to the appropriate standards and reads the flow data accurately. However, it is good practice to inspect and verify the monitoring equipment quarterly (and provide for offsite calibration if measuring outside the 5 percent margin of error) to ensure the accuracy of the equipment. Records of field checks should also be maintained to show the good-faith effort of the facility to ensure the accuracy of their monitoring equipment. Equipment manuals describe best-practice operation and recommended maintenance and calibration procedures. Staff involved with the GCCS monitoring and operation should be familiar with the guidelines included in these manuals.

Equipment Standards

The standard conditions of the monitoring equipment should be reviewed prior to the GCCS startup. In the emission reduction calculations, the Reserve uses a standard temperature of 520 degrees Rankin and a standard pressure of 1 atmosphere. Monitoring equipment standard temperature may vary (though typically most equipment uses a standard pressure of 1 atmosphere) and emission reduction calculations will require a conversion if the monitoring equipment is not calibrated to this standard. Though it is not necessary to specify that the equipment is laboratory calibrated to this standard, it is important to be aware of the equipment operating standards to ensure proper accounting of emission reductions.

Another important aspect of equipment standards is reviewing the GCCS flare operating parameters. The minimum temperature of the flare at which methane destruction occurs should be reviewed and compared with the flare operating records. There may be a calibration error in the tracking equipment, and if the records show an operating temperature below the minimum methane destruction temperature listed in the flare equipment manual, the facility may not be able to claim credits for this operating period. In general, the monitoring data should be reviewed against the equipment operation parameters to ensure the data is reliable.

Multiple Destruction Devices

Facilities may use more than one equipment destruction device to combust the collected methane. The facility may use a landfill gas (LFG) fueled engine to generate electricity and use a flare for backup, or may divert a small portion of the collected methane for onsite use. No matter what the GCCS destruction device setup is, it is important to have some type of monitoring device on each individual destruction device. Current Protocol allows for flow and methane quantity tracking to encompass all site destruction devices under specific circumstances, but the project developer must have documentation in instances of downtime for one of the destruction devices and assurance that the flow previously sent to the down destruction device is captured and destroyed. The project developer should evaluate their current plan for operating the destruction devices and whether it makes sense to track the flow and methane content separately (and subsequently calibrate and maintain the monitoring equipment) for each onsite destruction device to ensure they are maximizing the verifiable credits that may be able to be obtained for the project.

Pre-Project Qualifying Destruction Device

As discussed in the previous section, the Reserve goals include the development for “business as usual” or baseline emissions. This comes into play for facilities that implemented some type of methane destruction prior to implementing a GCCS. This may have been the use of passive flare vents for LFG management or odor control, or diverting the gas for some type of onsite use such as leachate evaporation. In this instance, the Reserve typically requires a quantification of the emission reductions associated with this activity as a baseline emission, and deducting the emission reductions from the amount credited to the Protocol eligible project. This requirement ensures that the Protocol eligible project is providing emission reductions that are additional to what the facility’s baseline emission reductions were. Typically, facilities may not have the proper documentation of this pre-project operation, and therefore the Reserve has typically required that the maximum operation values for the destruction equipment be used to determine these baseline emission reductions in an effort to be conservative in the emission reduction credits allotted to the Protocol eligible project. If the facility has proper documentation for these pre-project devices, it is prudent to use these values to calculate the baseline emissions to provide for a more accurate quantification.

Credit Purchaser Standards

Beyond complying with carbon offset program protocols and verification standards, current voluntary carbon offset credit market conditions indicate that it is a “buyer’s market”. Although most voluntary carbon offset verification programs offer highly credible verification standards, purchasers of carbon offset credits for non-compliance purposes have the luxury of evaluating the project beyond the measures laid out for project applicability in a carbon offset program. In other words, although the voluntary GCCS project may be accepted and verified in a carbon offset program, the purchaser may wish to see efforts undertaken by the project developer outside the voluntary GCCS. For example, ensuring an effective recycling program is in place or the pursuit of a landfill gas-to-energy project is underway. Non-compliance purchasers of carbon offset credits are in a position where they may wish to purchase credits from a project showing environmental stewardship above and beyond carbon management.

Evaluate Your Current Operation Practices

Municipalities interested in implementing a voluntary GCCS that are also interested in pursuing carbon offset credits in conjunction with the GCCS operation should thoroughly evaluate their current operation practices, along with staff capability to properly implement the Protocol requirements. A pro-active approach will ensure that the municipality is able to obtain the maximum amount of offset credits for the project.

Cami Van Abel, P.E. is an environmental engineer with the solid waste section for SAIC in St. Paul, MN. She has more than 10 years of experience as an environmental consultant. Her experience in the solid waste industry includes providing design and regulatory compliance assistance for landfills and landfill support systems. Cami may be reached at (651) 994-8415 or by via e-mail at [email protected].

Reprinted with permission. All rights reserved. From WASTECON® 2011 Proceedings. Published by the Solid Waste Association of North America, 2011.