Pat Sullivan

Landfill gas (LFG) migration impacting neighboring properties is not a new concept. However, increasingly we are seeing lawsuits filed by neighboring land owners claiming a variety of health, safety and/or environmental impacts resulting from their alleged exposure to LFG and its constituents. These lawsuits can create significant liability for the landfill owners due to potential litigation awards and settlements, regulatory action and negative public opinion that can damage efforts for future landfill projects like expansions or new operations. Even when cases are won, significant monies can be spent in defense against the lawsuit.

Defending landfills against these lawsuits can be expensive and complex. It is well known that LFG migration and its impacts on the environment are difficult to quantify. However, through several legal cases and projects, specific quantitative and semi-quantitative tools for evaluating offsite LFG migration and impacts have been developed. One of these tools includes “fingerprinting” LFG for the purposes of comparing it to detected gaseous impacts in the subsurface and tracking those impacts back to the landfill. The fingerprinting technique can also be used to trace the source of methane (the primary component of LFG) to its source, which can include LFG but also natural (thermogenic) gas, petrogenic (petroleum-derived) gas or other sources of biogas (e.g., swamp gas).

In some cases, it can be shown that the offsite detections of methane and other “typical” constituents in LFG are not from LFG but from other industrial, commercial, residential or institutional sources, which can cause similar contamination containing one or more of the constituents in LFG.

Regulatory Requirements

There are very limited regulatory requirements that apply to subsurface migration of LFG, and these requirements are focused on the potential fire or explosion hazard resulting from the methane in LFG. Under federal landfill regulations contained within Resource Conservation and Recovery Act (RCRA) Subtitle D, or state equivalents, LFG migration is limited to less than 5 percent methane at the landfill’s permitted facility boundary. Monitoring is required to assess compliance using subsurface gas monitoring probes installed at the point of compliance around the landfill.

Methane is potentially explosive in the range of 5 percent, which is the lower explosive limit (LEL), to 15 percent, so limiting offsite impacts to less than 5 percent is intended to ensure that concentrations in the explosive range are never allowed to leave the landfill facility. Within the landfill facility, methane is limited to less than 1.25 percent in onsite structures, which provides an additional margin of safety by setting the compliance level at 25 percent of the LEL.

The compounds that make up LFG, including many toxic organic chemicals, are not specifically regulated in terms of subsurface LFG migration. Airborne releases of LFG are regulated by federal, state or local air agencies, some with the ability to limit health risk caused by these toxins. Odor or nuisance caused by airborne releases of LFG can also be regulated by air agencies, solid waste agencies or by other local ordinances. However, the only case when subsurface migration is directly regulated pertains to the aforementioned methane limitations or when LFG impacts groundwater and causes chemical concentrations to exceed regulatory action levels for groundwater impacts. Due to this lack of specific regulation, suspected subsurface LFG impacts on neighboring properties have sometimes been handled through legal action, which can be a very cumbersome and expensive way to address the issue.

Case Studies

Provided below are summaries of two projects where the alleged subsurface migration of LFG resulted in litigation or major regulatory action. As part of each case study, the techniques used to assess and quantify the LFG migration and to determine the source of the impacts are also explained.

Highway 59 Landfill

The Highway 59 Landfill, located in the County of Merced, CA, has been in operation since 1973. The site is approximately 609 acres and includes four unlined units (89 acres), one composite-lined unit (23 acres), a 200-acre expansion area, a lined leachate management pond, several unlined storm water management ponds and a wetland preserve (168 acres). Groundwater monitoring began at the site in 1988 with 31 wells in the system (some are no longer in service), and LFG monitoring began in 1998 with 24 multi-zone gas probes (SCS Engineers, 2011). In June 2008, a local family filed a complaint against the County claiming (among other things) diminution of property values due to contamination beneath their adjacent property, caused by the landfill. At the time the initial complaint was filed, the plaintiffs had collected no data on their property to support their position, but based the claim on documents available through the public record, including the historic monitoring data for the landfill. Between August 2008 and August 2010, the plaintiffs’ environmental consultant collected a few samples of soil gas and groundwater from underneath the plaintiffs’ property, which is located across the highway from the landfill, using various methods. Using the few sample results obtained from their property, and the large historic set of monitoring data from the landfill, the plaintiffs argued that their data showed environmental impairment caused by the landfill. The case was tried in US District Court, Eastern District of California, in January 2011 and a decision was rendered in February 2011. This case is used as an example of how publicly-available monitoring data from a landfill can be used by a plaintiff to claim environmental impairment, and how the validity of environmental data can be questioned in court, and have a significant influence on the court’s decision.

The plaintiffs argued that sampling conducted on their property showed environmental impacts to groundwater and soil gas under their property, resulting in diminution of property value; however, they collected only a few samples, the sample collection methods were questionable, sample collection were not done in compliance with their documented standard operating procedures, and their quality assurance/quality control (QA/QC) samples were not appropriate and/or failed QA/QC tests. The plaintiffs dropped the claim of groundwater impact after their own data were unsupportive of that claim.

The plaintiffs continued to press their case based primarily on soil gas data from four soil gas samples, collected on two occasions, separated by almost two years, and collected using different methods. Much of the data they collected did not correlate between sampling events, but the plaintiffs claimed they detected low concentrations of some volatile organic compounds (VOCs) in soil gas, mostly compounds that are commonly petroleum-related (e.g., benzene, toluene, ethylbenzene, xylenes [BTEX]) compounds. The plaintiffs argued that since these were detected on their property, and that some of these VOCs had also been detected in LFG at some time, the impacts must be caused by the landfill.

This argument ultimately failed for several reasons including: (1) the plaintiffs’ data collection methods for soil gas were inappropriate; (2) their QA/QC data were incomplete and the duplicate sample data did not provide reproducible, and thus defensible, data; (3) they failed to test soil gas for the most important and predominant components of LFG—methane and carbon dioxide; and (4) the VOCs they claimed to have been detected did not match the predominant species of VOCs known to be present in LFG, such as the chlorofluorocarbons (CFCs or Freons), and other chlorinated hydrocarbons.

The defendant’s expert witness was able to show that a “fingerprint” of VOCs that the plaintiffs claimed to have detected on their property did not match any LFG fingerprints obtained from the large set of historic LFG data. The fact that the VOCs alleged to be detected on the plaintiffs’ property were primarily BTEX compounds, which are not the only or most common components in LFG, and in some cases were detected at higher concentrations offsite than detected in LFG, suggested that the VOCs were from another source, either a fuel release or sampling cross-contamination.

In the Memorandum of Decision rendered by the court in February 2011, the judge stated, “Defense expert [name], a geologist for SCS Engineers, testified at length regarding problems with the testing performed in Lot 1 [Plaintiffs’ property]. He concluded that the tests performed by the plaintiffs were “indefensible” and could not be relied upon. His testimony on the subject was unimpeached.” The court also found, “According to (defense witness name), there was no “fingerprint match” between the chemicals found in the landfill and those found in Lot 1. This makes it much less likely that the chemicals in Lot 1 came from the landfill. Migration from a landfill would almost certainly contain methane, carbon dioxide, and freons. Freons were found in the landfill but not in Lot 1, and the plaintiffs failed to test for methane and carbon dioxide.” (U.S. District Court, 2011).

The plaintiffs’ inability to show a match to the known LFG fingerprint, as well as the indefensibility of the plaintiffs’ data, played a significant part in the court’s decision. Without applicable and defensible environmental data to support their case, the plaintiffs were unable to prove their case based on a preponderance of the evidence. The court found in favor of the County (defendant) and further found the case to be frivolous regarding damages.

Even though the landfill operator was successful in its defense, the cost of the defense was approximately $500,000, including in-house counsel and retained expert witnesses. The court has since awarded recovery of attorney fees to the defendant, and a motion has been made to recover other associated costs of defense. However, recovery of legal and expert fees is uncommon, and in most cases, a prevailing defendant still bears the brunt of its own cost of defense.

OII Landfill

The former Operating Industries, Inc. (OII) Landfill is a closed refuse disposal site located in Monterey Park, CA. The OII Landfill accepted about 30 million tons of municipal solid waste and 300 million gallons of industrial waste between 1948 and 1984. OII was designated as a Superfund Site in 1986, and remediation work at the landfill is currently being performed by New Cure, Inc. (NCI) under the supervision of the U.S. EPA (Pierce and LaFountain, 2000).

The former OII Landfill was faced with regulatory action due to methane detected above 5 percent in facility LFG monitoring probes (Pierce and La Fountain, 2000). This situation was exacerbated by the fact that the landfill was a Superfund site. In compliance with EPA requirements, NCI maintains a network of gas monitoring probes (GPs) around the perimeter of the landfill. The purpose of the GPs is to detect migration of LFG away from the landfill. In addition to the perimeter GPs, a number of off-site GPs and water meter boxes are currently being monitored.

It was suspected that not all of the methane detected in some of the monitoring points at the OII Landfill was of landfill origin. LFG is one of many sources of methane in the natural environment. If methane is found when monitoring near landfills, it is generally presumed that the source of the methane must be LFG. This presumption can result in compliance problems for the landfill owner. If the methane is actually from a non-landfill source, there is virtually no possibility that the LFG control system can reduce the observed methane concentration to a 5 percent methane standard. If the methane is of non-landfill origin, it is necessary to conclusively determine this to be the case in order to secure regulatory exemption for the non-compliant monitoring locations. If this determination is not made, the landfill owner will incur costs, regulatory scrutiny and other liability in attempting to solve an unsolvable problem.

All methane can be divided into two categories: thermogenic gas and biogenic gas. Thermogenic gas is derived from the thermal decomposition of deeply buried organic material as a result of geologic processes and time frames; however, biogenic gas is derived from the microbial decomposition of organic material.

Thermogenic gas is what is commonly referred to as “natural gas”; it can be indigenous, or it can be imported into an area by pipeline. Because thermogenic deposits are deeply buried, when thermogenic gas is found near the surface it is generally present due to:

- Indigenous gas from improperly abandoned gas or oil wells

- Imported gas from leaking low-pressure local gas distribution piping, leaking higher-pressure gas transmission piping and leaking subsurface storage reservoirs

Biogenic gas can originate from a number of sources, including LFG, drift gas, swamp gas and marine sediment gas, as well as gas produced from anaerobic decomposition of any organic material. Miscellaneous sources of biogenic methane can include methane originating from anaerobic decomposition of petroleum materials or waste buried outside the landfill perimeter. Petroleum hydrocarbons may be present from leaking tanks or abandoned oil wells.

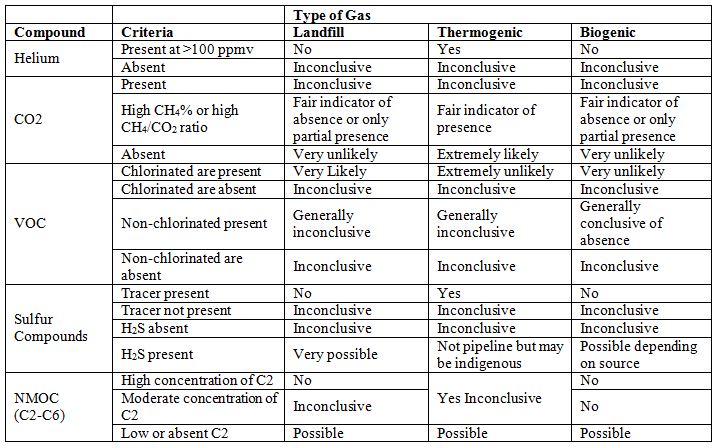

All methane is chemically the same and consists of one carbon atom and four hydrogen atoms. Most methane characterization techniques rely on the occurrence or the lack of occurrence of other compounds with methane in a gas sample. This type of “elemental analysis” assesses the presence of other chemicals which are present with the methane in order to assist in determining the source of the methane, including helium, carbon dioxide, high molecular weight VOCs, sulfur compounds and low molecular weight NMOCs. Table 1 (Pierce and La Fountain, 2000) contains a summary of conclusions that can be drawn from chemical analysis and comparison of the above constituents in the gas (so-called “elemental analysis”).

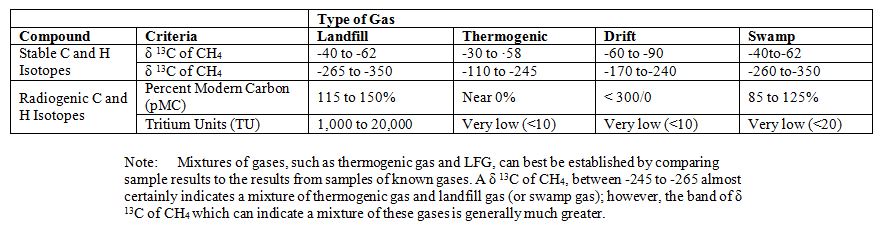

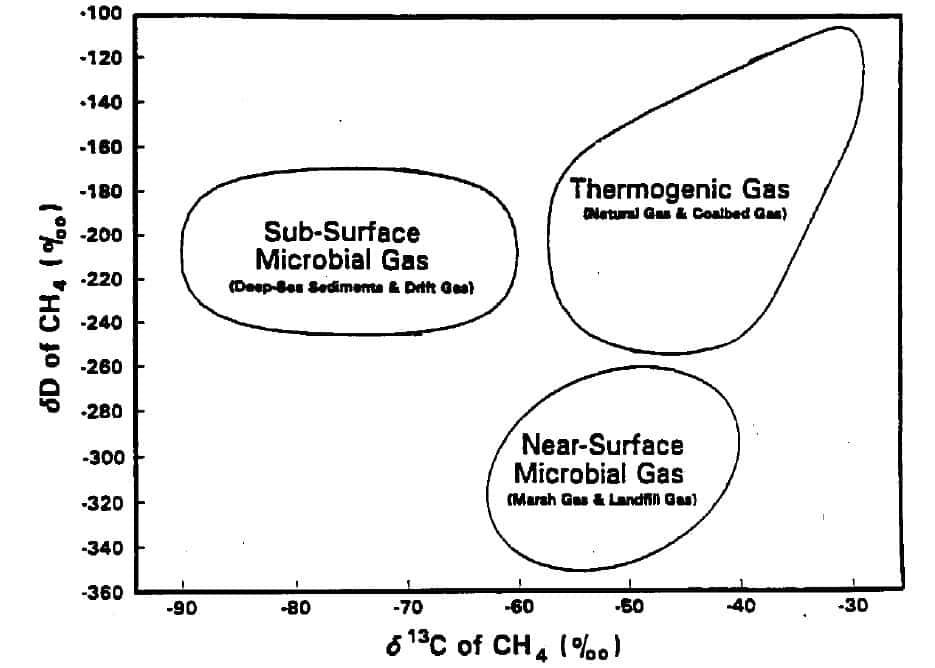

Further, the gas samples can be subjected to an additional isotopic analysis to provide better gas fingerprinting. Carbon and hydrogen isotopic analyses can be employed to distinguish between various sources of methane. Both the stable isotopes and the radiogenic isotopes can be used for methane characterization as well. Coleman (1994) discusses the theory and application of isotopic analyses in identifying the source of methane. The paragraphs that follow summarize the theory and application of isotopic analyses. However, the reader is referred to Coleman’s paper for a more thorough discussion.

Carbon and hydrogen each have three naturally occurring isotopes. Two isotopes are stable and one is radioactive. Carbon-12 (12C) and Carbon-13 (13C) are the stable isotopes of carbon. On average, 12C is 100 times more common in nature than 13C. Carbon-14 (14C) is carbon’s radioactive isotope. By comparison to 12C and 13C, 14C is extremely rare. Hydrogen-1 (1H or protium) and Hydrogen-2 (2H or deuterium) are the stable isotopes of hydrogen with 1H being the common stable isotope. Hydrogen-3 (3H or tritium) is hydrogen’s radioactive isotope.

A comprehensive sampling and analysis program was undertaken at the OII Landfill between July 1998 and March 1999 that focused on suspicious GPs. An elemental analysis as well as both stable isotopic and radiogenic isotopic analyses were employed. Stable isotopic analysis is less expensive and was applied to all samples. Radiogenic isotopic analysis is more expensive and was used to confirm the stable isotopic analyses, and to clarify a few ambiguities left by the stable isotopic analyses. Stable isotopic analyses were run on 65 gas samples and included the determination of:

- δ13C of CH4 (isotopic ratio of 13C to 12C);

- δD of CH4 (isotopic ratio of 2H to 1H); and

- δ13C of CO2

A total of 20 samples were subjected to radiogenic isotopic analysis, including 14C of methane, 14C of CO2, and 3H of methane. Table 2 and Figure 1 detail how these isotopic data can be used to differential between sources of methane.

The former OII Landfill lies in a location that is adjacent to a natural gas deep injection storage facility along with abandoned oil wells and an active oil field that would lead one to suspect that some of the monitoring probes might be influenced by non-LFG. Isotopic analyses of both stable and radiogenic isotopes were used successfully at OII to demonstrate that some of the perimeter and offsite monitoring locations were impacted by methane from non-landfill sources. Without the use of isotopic analysis, it would have been difficult to identify indigenous thermogenic gas as the source of much of this gas. In addition, the use of isotopic analysis countered the perception that the lack of helium ruled-out thermogenic gas. Isotopic analysis removed ambiguities that would have remained using only elementary characterization techniques. It allowed a regulatory exemption to be granted for the detected methane in the gas probes.

Since the OII project, the same fingerprinting techniques have been used on numerous landfills to either confirm the source as LFG or to demonstrate that some or all of the detected methane at a particular site was from a non-LFG source. Regulatory action has been avoided in each case where it was successful, and could also be used as a tool in litigation if offsite methane from LFG became the cause of legal action.

Pat Sullivan is Senior Vice President for SCS Engineers (Long Beach, CA). He has more than 22 years of experience in the area of environmental engineering, specializing in LFG and air quality issues for solid waste facilities. He is the Chairman of the Rules and Regulations Committee of the LFG Division of SWANA, chairman of the Waste Industry Air Coalition and co-chairman of the Solid Waste Industry for Climate Solutions. Pat is also the Vice Chairman of the Mother Lode Chapter of the Air and Waste Management Association and is on the Executive Board of the California Biomass Collaborative. A national expert on assessing impacts related to LFG and its constituents, he can be reached at (916) 361-1297 or via e-mail at [email protected].

References

- Coleman, D.D. 1994, “Advances in the Use of Geochemical Fingerprinting for Gas Identification,” American Gas Association Operations Conference, San Francisco, CA.

- Pierce, J.L., and LaFountain, L.J., 2000, “Application of Advanced Characterization Techniques for Identification of Thermogenic and Biogenic Gases,” Proceedings of the SWANA LFG Symposium, March 2000.

- SCS Engineers, 2011, “Revised Engineering Feasibility Study, Waste Management Units 1 through 4, Highway 59 Landfill, Merced County, California.

- U.S. District Court, Eastern District of California, 2011, “Memorandum of Decision – Crane, et al v. County of Merced.”

Table 1

Summary of conclusions that can be drawn from elementary characterization indicators.

Table 2

Summary of conclusions that can be drawn from isotopic characterization indicators.

Tables fromPierce and LaFountain, 2000.

Figure 1

Carbon and hydrogen isotopic compositional typical ranges of methane from different sources.

Figure courtesy of “Advances in the Use of Geochemical Fingerprinting for Gas Identification,” Coleman (1994)