Finding the right power take-off for your application is not that complicated if you follow some basic guidelines. However, you do need to take care to ask the right questions.

Mikel Janitz

I was conducting some training the other day at a large truck dealership. The class was filled with parts guys, service people, managers and inside and outside sales folks. After the introductions, coffee and donuts, we started the PTO class (see Figure 1). I found out that most of them had little to no hydraulics or power take-off experience. I knew this would not be easy since we were starting from scratch. So, I focused on the basics to keep it simple.

The main point I talked about was, “It all starts with you having a conversation with your customer.” Keep it simple. There are forms to follow and checklists to fill out but having a conversation so you understand the application and understand their needs is key to your customer’s solution.

Details

To be successful in selecting the correct PTO/Pump combination, you need to get three pieces of information. First, what kind of truck are we talking about? Get the make and model and year. Second, what kind of engine and transmission combination does that truck have on it? Can they give you manufacture’s name, serial numbers or model codes? Thirdly, what is the task? What will the truck do—dump truck, refuge truck or run a hydraulic motor? For this shop class group, they had not spec’ed a PTO before, so we dug a lot deeper.

The truth is most people don’t want to fill out a check sheet. Customers don’t want to be peppered with a bunch of questions for which they don’t have answers. The more it feels like a natural conversation, the better your outcome. Moreover a reputable PTO manufacturer will have a guideline to follow. Once you read over and understand it, you will realize there is a natural flow to get you to the end.

The Phone Call

It all starts with a phone call to the parts/service person. Typically it goes like this: “Hey I need a PTO real fast! Do you have one on the shelf we can have? Today! Oh, how much is it? Will it work?” You can feel the sense of urgency in their voice. They feel like they don’t have time for a lot of questions. They just need a PTO. Also, you are probably not the first place they called and they are frustrated. This is your opportunity to shine as a service center or parts shop.

First be very calm. They may not have all the answer. You know there are many ways to solve their problem. That is the nice thing about mobile power. There is more than one solution to any given PTO/pump combination application. No worries.

Complete the Order

To properly size and configure a PTO you need to get the following information:

- Truck make and model

- The engine and transmission manufacture model numbers

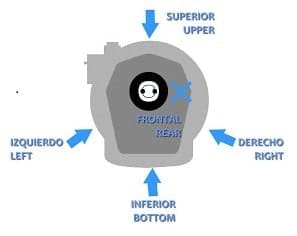

- The PTO bolt pattern and location (6, 8 or 10 – left, right or bottom)

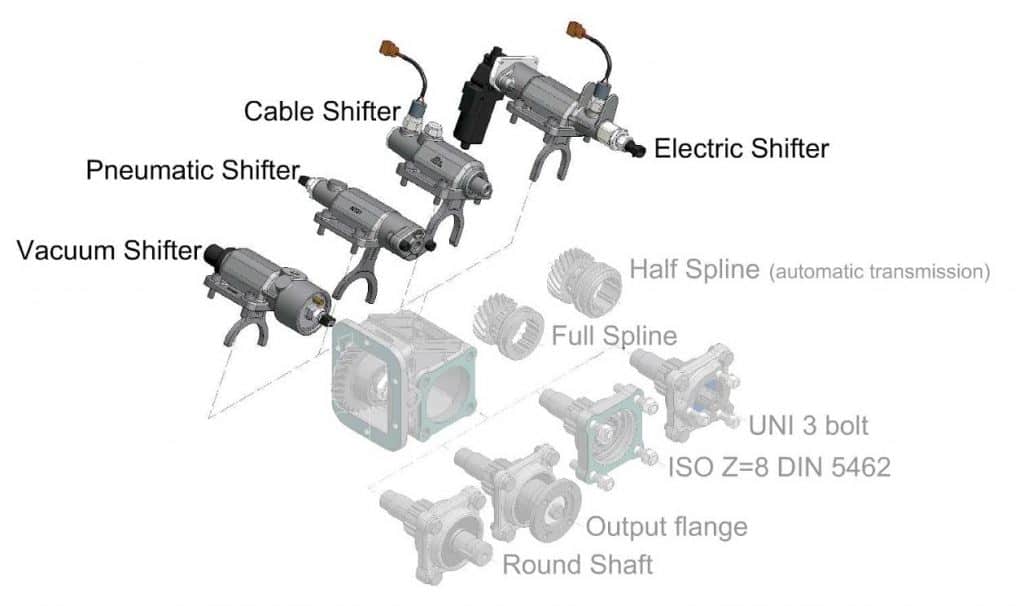

- Does the PTO shift by air, hydraulics or electrically (see Figure 2)

- If it is a replacement, the make and model on the old one

- The truck application

- Describe the pump

- The gpm, pressure, horsepower or torque requirements

As the conversation progresses help them along with suggestion to the questions. Offer up truck names, transmission manufactures, engine types and other tidbits to spark a natural conversation like PTO controls, shift types, pump manufacturer, and styles and mounting options. The goal is to get as clear a picture as you can to help them get the PTO. It will make your life easier too.

The Devil is in the Details

Your goal is to get the customer up and running as quickly as possible. To do that in the most cost-effective and efficient way, you need more details, if possible. Try to get a few more specifics above and beyond the first conversation, then go to the application book:

- How fast do they run their engine rpm?

- Is the truck in a stationary or mobile mode?

- Is this a continuous running application or not?

- Is the pump direct mounted or shaft driven?

- What is the rotation on the pump (CW or CCW, some people say left or right hand rotation)?

The Solution

Now that you have that information jotted down, you need to provide the solution. After you do this a few times, you can search it out while they are still on the phone with you. A quality PTO manufacturer will have an application book or reference guide to assist you online with the detail process. For example:

- Find the make and model of the transmission

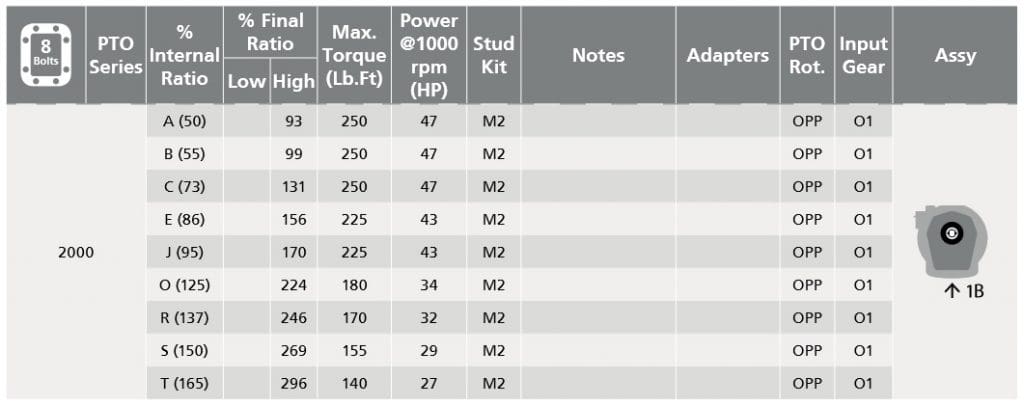

- Click on the transmission number and up pops the page with all the PTOs that fit that transmission (see Figure 3)

- Locate the bolt pattern

- Find the location where the PTO will mount (see Figure 4)

- Verify the speed, HP and torque meet or exceed the requirement

- Find PTO, engine speed, torque, output rotation and mounting location combination to best meet their needs

- Ensure the rotation is correct to mate with the pump

Finishing Up

The final step in this process is configuring the PTO by using the PTO technical data sheet. The technical data sheet will show you how to construct the PTO part number so it can be assembled correctly. For example, the first four digits are the PTO Series. The first letter is the Version, next is the PTO Internal Ratio. The third letter is the Shifter Type. Then, there is a two-digit set for the Input Gear and the next digit is for the Assembly Arrangement. Typically the last two letters are the Output Type.

Now you can provide your customer with a PTO part number for a correctly configured unit to help them to get back to work, making money and building our world.

Mikel Janitz is a Bezares OEM Application Sales Engineer based in Tulsa, OK. Bezares is a global leader in engineering and manufacturing PTOs and Pumps. Mikel covers the mobile power industry and holds several patents. He can be reached at (918) 953-9062 or via e-mail at [email protected].