A farm powered solution offers hauler partners new destinations for organic waste with easy truck access, lower tipping fees and the ability to attract new customers. All this while helping to sustain a local farmer and protecting the environment.

By John B. Hanselman

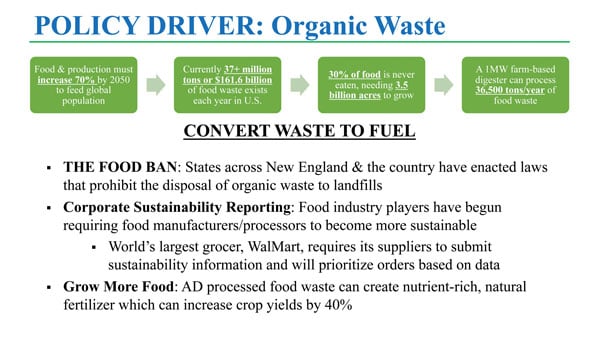

Look in your garbage. Look at the dumpster at the grocery market. Look at your tray at a fast food restaurant. Once a person is cognizant of it, it becomes clear that food waste is everywhere. In fact, 40 percent of the total waste stream in the U.S. is organics. In the past, the majority of that tonnage has been sent to landfill or incineration, but all of it can be recycled. This equaled approximately 133 billion pounds of food in 2010 per the USDA’s Economic Research Service. The first challenge to extracting the organics from the waste stream is to create an awareness of what food waste is. The second is to create a new food waste collection, processing and disposal paradigm. In several markets in the US, this is happening, and it presents a huge opportunity for the waste community.

Currently, much of the collected food waste is still sent to landfill where it garners no further value. If recycled, what was once waste can be used to produce renewable energy and/or high value byproducts and thereby, the food waste creates new value. The first step in “capturing” this unrealized gain is to locate where this unused resource is and develop collection and processing system to get it to recyclers. With tipping fees continuing to rise at the rate of 6.3 percent between 2017 and 2018 and landfill and incinerator capacity rapidly decreasing, haulers need a destination for organic waste and recyclers with capacity can become close allies to everyone’s benefit.

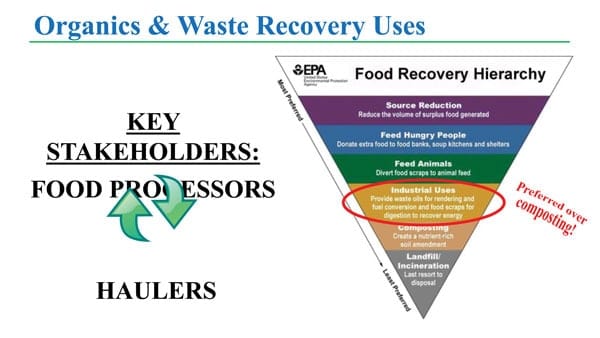

The two coasts are ahead of the curve on food waste recycling, with multiple states and cities creating source separation of organic materials laws. These laws require organic waste generators to separate the organic materials from the trash and send it to compost or anaerobic digestion (AD) for disposal. Compost is widespread across America but has specific volume constraints due to odor concerns. Because AD takes place in sealed facilities, odor is less of an issue, but the contamination levels of the organics stream needs to be much lower than for some compost operations. The adoption of AD has been varied across the U.S. as every state has a different program for the sale of renewable energy resulting from the anaerobic digestion process.

With food waste recycling, the only difference in the value of the waste is how much pre-recycling processing is needed. If the waste needs to be removed from the packaging, it becomes less desirable and therefore costs more to recycle. What has become clear to those practicing the art of organics recycling, is that a dedicated infrastructure chain must be constructed to separate, clean and process the waste stream.

Challenges and Benefits for Food Waste Producers

Behavioral change and education are required for food waste producers to effectively get on the recycling bandwagon.

Waste Identification, Education and Worker Training

Much of food waste is still in packages or co-mingled with contaminants like packaging, plastic bottles, utensils, cans and cardboard. The first step in the creation of a food waste infrastructure is employee education at the food waste producer’s business. Food workers and waste collection employees need to understand the separation requirements for the waste streams that can be recycled. Process waste, wash water, grease and grease trap cleanings are often overlooked as potential recycling opportunities and non-saleable packaged goods require the pre-processing step of depackaging at an Organics Recycling Facility (ORF). Some recyclers have their own ORFs, but increasingly, waste management companies are getting into this arena to build business revenue and volumes.

The separation and recycling model has already become commonplace in the waste industry with the recycling of cardboard. Cardboard used to be co-mingled with all other waste and thrown out with the trash. Today, corrugated “cardboard” is recycled more than any other packaging material in the U.S. In 2016, per the Corrugated Packaging Alliance, the recovery rate for old corrugated containers was 93 percent up from 54 percent in 1993. As tip fees continue to rise, it will be beneficial for food waste generators to separate organics from the waste stream and divert it to a lower cost disposal option like compost or AD.

Collection

Once the workforce is educated on the potential sources of food waste, it is now critical to collect and process the different waste streams. The first challenge is to collect the tonnage in the appropriate containers. Food waste often has a high liquid content making it heavy and it can have unpleasant odors. Sealed compactors, totes, tanks or other tight containers are an absolute necessity in the first stage of the process. Maintenance and cleaning of the containers is also critical to any program’s success. In most cases, the reason for lost customers is odors or accumulated mess at untended collection areas.

Separation

After collection, the organics processing equipment is the next critical step. End disposal sites will either reject organics loads that are too contaminated, or risk losing their permits if they are processing too much inorganic materials. Given that food waste comes in many different forms, levels of packaging and contaminants, the amount of processing necessary to separate the organic component from the packaging determines the necessary mode of processing and the type of equipment. The U.S. market is benefitting from the European market’s decade of experience and most of the equipment available in the U.S. for depackaging or separation has European roots. Across the US, dedicated facilities are springing up to handle the organic processing. Without these facilities, it is impossible to create a consistent and dependable stream of organics for composting or anaerobic digestion.

Cost

A motivator for the food industry is cost savings and the potential for business growth. On the cost-side, food waste generators do not want to pay more for recycling than they have traditionally paid for disposal. Because recycling food has a value and is not just wasted, the cost is on par with disposal and less than that of alternative recycling methods. The appeal of food waste recycling to producers creates a business expansion opportunity for the waste hauling community with new destinations available for organic waste.

Customer and Employee Attraction and Retention

Recent studies have shown that consumers make purchasing decisions based on whether a company recycles and has a strong sustainability mission. In fact, a survey conducted by The Recycling Partnership found that 74 percent of Americans polled said they would rather shop and spend money at a “green business,” or a business that makes every effort to recycle and reuse materials, than a non-green business. In addition, a study by Swytch found that 35 to 40 percent of employees favor working for greener companies. This awareness amongst consumers about the need to curb environmental impacts that are affecting public health, offers food waste generators an opportunity to present a strong sustainability mission and brand platform that will generate business. This can also be a benefit to the waste hauling community in attracting and retaining business.

Food Waste Recycling Options

On-Farm AD Co-Digestion Facilities

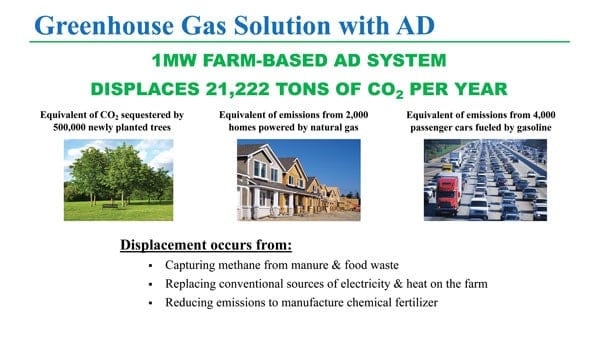

The farm-based AD process converts the energy potential in farm and food waste into renewable electricity or renewable natural gas (RNG). Food waste producers get a safe, clean and certifiable food waste recycling solution that complies with food waste bans and haulers get a new destination for collected waste. These AD systems also benefit the environment by reducing greenhouse gas emissions by more than 85 percent. Even better, host farms get paid for the use of the land and some relief from ever-rising energy costs and manure disposal challenges.

Non-farm organic waste is collected by the hauler and delivered via sealed trucks to a dairy farm where it is combined with manure in a sealed biodigester tank. Microorganisms convert the sugars, fats, and other compounds into biogas, which generates renewable energy in the form of RNG or renewable electricity and provides heat to the farm. The remaining digested material is odor-free, nutrient rich fertilizer that increases farm crop yields.

Images courtesy of Vanguard Renewables.

Composting

Composting is a viable food waste recycling method; however, like landfills, it does not solve the methane emissions/air quality issues challenging climate change as those emissions are still present as part of this process. The aerobic decomposition of organic materials by microorganisms under controlled conditions into a soil-like substance, composting facilities are aerated or unaerated and covered or not covered. Composting methods include passive piles, windrows, static piles and in-vessel composting (in bins, beds, silos, transportable containers and rotating drums). For waste haulers, composting offers another solution and can be a good food waste recycling destination when AD is not available in the service area.

The Bottom Line

Food waste collection and recycling is a sustainable solution that offers haulers an efficient, beneficial destination for organic residuals and the greatest environmental benefit for communities. A farm powered solution offers hauler partners new destinations for organic waste with easy truck access, lower tipping fees, and the ability to attract new customers. All this while helping to sustain a local farmer and protecting the environment. | WA

John B. Hanselman is Chairman and Chief Executive Officer of Vanguard Renewables (Wellesley, MA). Named 2018 Organics Recycler of the Year by the National Waste & Recycling Association, Vanguard Renewables Farm Powered Anaerobic Digesters produce renewable energy from food waste and farm waste. John has 30 years of experience in environmental innovation including a Managing Principal and Founder of Brightfields, a solar brownfields solutions company and as a Managing Principal of Renova Partners, a national brownfield investment and development company. He has directed several of the nation’s largest private acquisitions of contaminated properties from Fortune 500 companies. He has been an invited speaker at Harvard Business School, Babson College and both MIT’s Sloan Business School and Center for Real Estate Development. He has numerous published papers and holds patents in the semiconductor and natural language software areas. John can be reached at [email protected].