Transfer Stations

Incorporating Health and Safety Considerations into Transfer Station Design

Ian K. Sutton

The solid waste industry is well recognized as one of the more hazardous industries. Transfer stations are a critical aspect of many solid waste handling processes and systems. These facilities are a unique situation in which commercial haulers and general public self-haulers mix with facility operators and visitors in a high-activity, confined area with many physical and environmental hazards. While well-designed health and safety measures cannot fully replace the personal decision-making of operations staff, the public and others, they can reduce the potential hazards. Health and safety considerations are an essential part of successful transfer station design, while maintaining a facility’s functionality. This article outlines the planning and design approach to address some of the many health and safety considerations made at the Bow Lake Recycling and Transfer Station (Bow Lake), in King County, Washington, to minimize risk to both the facility and the people using the facility.

Risks

Transfer stations have many safety and health risks as a result of the nature of the material being handled and the growing complexity of waste handling operations as modern facilities evolve to handle larger quantities of material requiring more separation and processing. The diversity of the facility users’ experiences operating in limited space with lots of moving equipment and vehicles also affects health and safety risks.

Primary users of the Bow Lake facility include operational staff, commercial haulers and general public self-haulers. Others, such as owner administrative staff, regulators, maintenance contractors and visitors (for example, tour groups), are also at the site at any given time. The commingled activity of this variety of facility users requires a broad spectrum of understanding and awareness of risks in order to create an effective design.

The day-to-day health and safety risks revolve around accidents and injuries associated with typical facility use. Some of these potential accidents and injuries may include:

Falls, slips and trips

Laceration, punctures and cuts

Flying objects and projectiles

Collisions (vehicle-vehicle, vehicle-pedestrian, vehicle-building)

Spill, splash, or release of acids, caustics and toxics

Material handling equipment moving parts

Falling material

Electrocution

Heart attacks and other medical or health emergencies

Other more uncommon or long-term health and safety risks may include the following:

Fire

Explosion

Confined space hazards

Environmental exposure (dust, noise, toxic fumes, exhaust gases and smoke, or infectious agents)

Stakeholders

Risk exposure varies greatly amongst facility users. Early recognition in the planning and design process can minimize and reduce these risks and result in facilities designed and constructed to provide for improved health and safety. Facility stakeholders who can contribute to this planning and design effort include:

Owner

Operations

Risk Management

Engineering

Health Department/District

Department of Labor and Industries

Code officials

Fire officials

Design professionals

Insurers

Governing codes and regulations can include:

International Building Code (IBC)

International Fire Code (IFC)

National Electrical Code (NEC)

Occupational Safety and Health Administration (OSHA) regulations

National Fire Protection Association (NFPA) standards

State administrative code

Local jurisdictional codes

Public health ordinances

Operating permits

Owner’s rules procedures

It is important to identify and involve stakeholders in the early stages of planning and design and maintain their involvement through project completion. The health and safety aspects of these facilities are large and integral to the physical arrangement of the facilities, and thus will not be easily addressed late in the design process without significant impacts to cost and possibly schedule.

Risks and Mitigation

Through planning and design, health and safety risks can be identified and to some extent mitigated. The following discussion pertains to tipping and receiving floor separation as an example of a risk and measures that can be incorporated to help mitigate the risk.

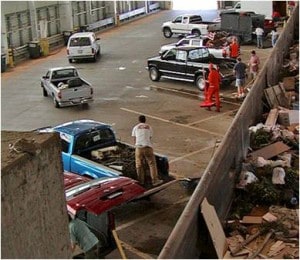

Within the main transfer building at Bow Lake, vehicle and equipment injury and damage risks will be ever present. These risks are accompanied by solid waste handling hazards, such as falls and injuries due to moving or projectile waste. The exposures to these dangers vary for the variety of facility users, primarily being facility operators, commercial haulers and general public self-haulers. Figure 1 is an example of a receiving floor waste handling area that is separated by a tipping wall to protect general public self-haulers.

Separation of activities is important to reducing injuries associated with moving vehicles and flying material. General public self-haulers should be kept out of the work zone of commercial haulers and waste handling equipment. The wall at Bow Lake will be concrete with armor plating to protect the facility against impacts and wear.

The tipping wall at Bow Lake will be 42 inches in height on the tipping side and eight feet in height on the waste handling side. While this size wall is needed as a safety measure, it does create a fall hazard. Some basic design strategies to prevent injuries from falls at this location can include:

Avoiding deep pits

Tipping walls and barriers

Stanchions and chains

Slip-resistant surfaces

Positive surface drainage away from areas where people may stand or walk

Integral floor warning marks

Striping and signage

Training and supervision

The use of tipping walls and barriers can be a challenge as they can conflict with customer convenience. Increased wall height can provide improved safety separation from falls, solid waste and waste handling equipment, but at the cost of functionality. Figure 2 shows another angle of a tipping floor where the facility operations waste handling area is separated from the general public self-haulers by a tipping wall.

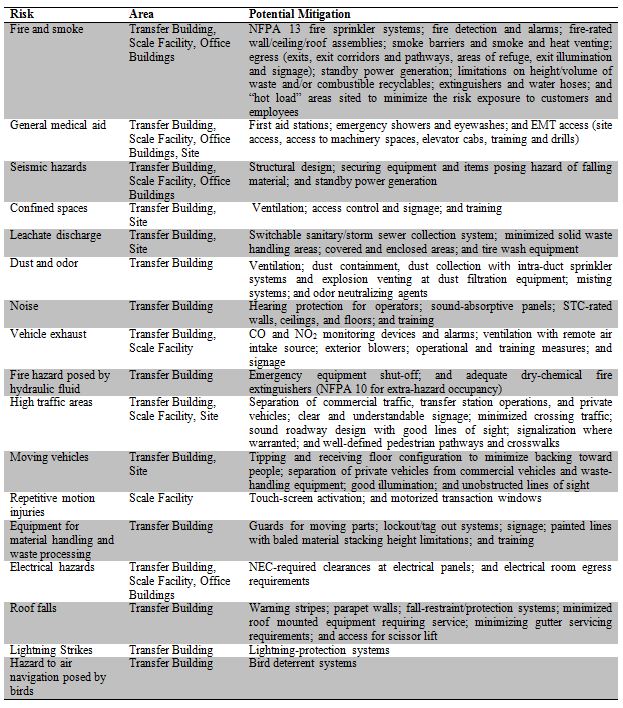

Table 1 identifies some other risks and potential mitigations to be considered in design. These examples are only some of the many issues that need consideration. All health and safety considerations for these complex transfer stations are numerous and beyond what can be discussed within this brief article, even in this limited detail. The emphasis here is that careful consideration of health and safety risks is vital to the successful development of transfer stations, and these risks need to be accounted for in the early stages of the planning and design process.

A safety team should be formed, including members of the design team, the owner’s representative, the owner’s risk manager, the owner’s insurance carrier (if appropriate), and local health, building, and code officials. This team should identify as many potential risks as possible early in the design process and identify stakeholders for additional input. Strategies to mitigate risks need to be developed and then continually evaluated throughout the design process. Also during construction, each incorporated safety measure needs to be properly commissioned and fully tested.

The owner should understand risks that will need to be mitigated partially or wholly through training or operational means. Though health and safety features designed within a facility help mitigate risks and hazards, they are not a substitute for proper training and good decision-making by those using the facility.

Ian K. Sutton is a project engineer in the Water, Environment & Transportation Operation of SAIC Energy, Environment & Infrastructure, LLC, a wholly owned subsidiary of SAIC (McLean, VA).He has 11 years of experience in solid waste and can be reached at[email protected].

Figure 1

Tipping wall.

Figure 2

Tipping floor.

Table 1

Risks and Mitigation

Images courtesy of SAIC.