Involving the customer in the design concept through the development process is not only satisfying for the supplier, but also rewarding for those who have been a part of the design process.

By Shannon Harrop

Product development engineers and marketing professionals know all too well that the product development process can include a whirlwind of emotions—exciting in the beginning when a new concept is hatched, tenuous during the mid-phases as the details are churned through and, ultimately, unnerving as the launch date nears. Has the product development team listened to the customer well and hit the mark when it comes to the most important factors of the design? Does the design solve the customer’s issue or pain point? There are designs, of course, that preempt the user’s knowledge of issues before they even knew they needed the solution, like the novel ideas of Windows or the iPhone. However, the best design ideas are generated directly from customers who are all too familiar with what is needed to make their lives less painful. If you address your customer’s pain points. you will become an endeared supplier.

Voice of the Customer

An experienced product development team has many years of observing pain points and listening to client’s needs. This listening process has been used to improve and refine existing product designs as well as develop completely new products. There is an art and a science to the process of listening to customers and developing products to meet their needs. The term Voice of Customer (VoC) best explains what we are listening for: VoC is a term that describes customers’ feedback about their experiences with products or services. The definition of VoC originated with a 1993 paper by Griffin and Hauser, who define it as “a complete set of customer wants and needs; expressed in the customer’s own language; organized the way the customer thinks about, uses and interacts with the product and service; and prioritized by the customer in terms of both importance and performance.”

The methods used to obtain VoC can be as simple as a phone conversation or a text photo portraying what is not working for them on a given day to a more involved Customer Focus Group with attendees deliberately chosen for their extensive knowledge of a particular product, process or operation. Their contributions will be most meaningful to the design outcome. Questions are posed in a group setting, discussion ensues and consensus builds with the most important design elements exposed. Computer-Aided Design (CAD) models of various concepts help communicate design intent.

Photos courtesy of tarpARMOR.

Design Through Development

Further refinement of the design comes later through feedback surveys and, ultimately, sign-off to build a prototype and begin a field evaluation. This is no small task as the equipment can be so large it requires a flatbed semi-truck to mobilize on site. However, there is no better validation of design intent than to receive customer approval after performing an extended field evaluation. The often lengthy, and sometimes financially risky, process of taking a

customer’s design concept through the development process and provide a solution that solves a long-standing issue is satisfying for the supplier, but most importantly, is rewarding for the customer who has been a part of the design process. | WA

Case Study: VoC Feedback

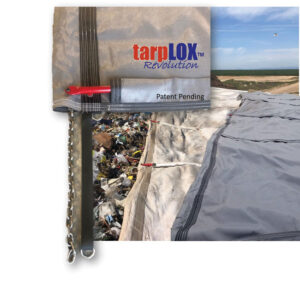

Even though longstanding tarpARMOR® customer Merced County Regional Waste Authority was experiencing much longer life and greater performance with tarpARMOR than any other brand of alternative daily cover tarp, Landfill Supervisor Alfredo Figueroa felt further improvement could be made. VoC from his long-term failure mode analysis of the tarp resulted in tarpARMOR engineers developing an improved cable ballast solution now marketed as the tarpLOX™ Revolution cable system, which provides extended tarp life and more compliant ballast cables.

Case Study: Focus Group Discussion

A customer focus group assembled from many prominent California landfill directors, supervisors and operators provided design validation and ideation that tarpARMOR directly included as key VoC into the product development of the all new tarpARMOR XS-series of tarp deployment systems used for alternative daily cover. The 30 and 40-foot models provide unprecedented performance and safety features as a result of the input. One noteworthy contribution echoed by many focus group participants was the need to raise the tarp deployer higher off the working face than a typical dozer blade will lift. The resulting patent pending TDS40XS with Hi-LIFT™ is in use at Orange County and Sacramento County landfills.

Shannon Harrop, BSME, MBA, is Sales and Marketing Manager for the tarpARMOR, a division of Southwestern Sales Company, and has more than 25 years of experience actively using VoC to develop products in all segments of the solid waste industry from collection, recycling and disposal operations, as well as many other industries. Shannon can be reached at (800) 678-7320 or e-mail [email protected]. For more information, visit www.tarpARMOR.com.