While the DPF industry has evolved over the last decade dramatically, the basic needs for service and maintenance has remained unchanged. Manufacturer approved cleaning methods must still be followed for proper cleanings.

By Mike Callaway

Since the introduction of Diesel Particulate Filter (DPF) systems, the need to properly and efficiently clean particulate filters has been a challenge. A variety of methods have been used to shortcut manufacturer approved methods of cleaning DPF systems. Everything from using a pressure washer to beating on the side of the filter has been tried to clean DPF systems and many have been damaged from this. However, by shortcutting manufacturer approved cleaning and maintenance methods, DPF systems are at risk of causing engine damage, loss of fuel economy, as well as reducing catalyst performance. Ensure that your DPF system is properly maintained to increase the longevity of your system, and to prevent any costly repairs, or possible downtime due to system failure.

Cleaning Methods

Diesel particulate filter systems must be cleaned and diagnosed by a qualified technician. Following the DPF manufacturers’ recommended maintenance schedule and methods will prevent expensive repairs down the road, and protect the manufacturer warranty. Use the “pulse-bake-pulse” method in cleaning and regenerating the filter, which ensures that soot is properly removed, and the filter is heated to the manufacturer’s specified temperature for proper cleaning and regeneration.

Despite the method used in the pneumatic cleaning portion of the process there should always be a baking cycle to accompany it. Controlling the DPF temperature over time during the baking cycle is called the “ramp rate”, and qualified technicians should be aware of the manufacturer-approved rates to keep your filter safe. Qualified DPF technicians should always diagnose and document the cause of filter plugging if possible, so the truck owner can perform the necessary repairs and prevent the need for premature cleanings.

Keeping a DPF’s History

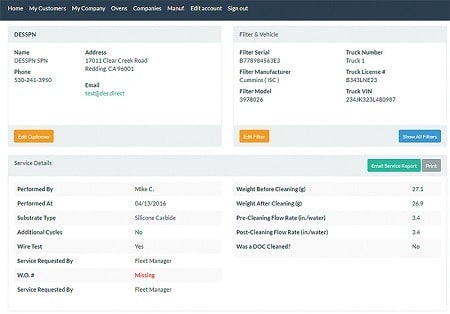

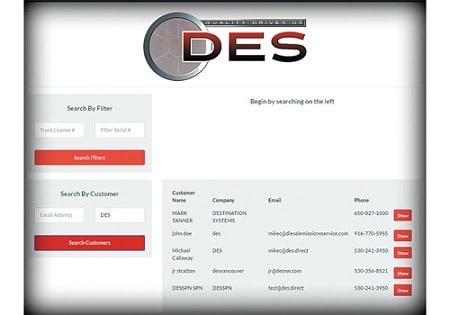

Paper documentation of cleaning services has been the standard in the DPF industry. Customers could only use old copies of invoices as support for any warranty case. The industry is now catching up with technology and the use of digital applications will become commonplace.1 The use of an online application allowing technicians to view complete filter cleaning history, as well as filter conditions pre and post-cleaning is a must. It allows technicians to search by Vehicle Vin, Filter Serial Number, or Company name to find the filter being cleaned. The ability for a technician to view the full history of the filter and previous technician’s notes help the customer stay informed, and assists in diagnosing a pattern causing cleanings before a regular service interval. Information regarding before and after flow rates, weights and pictures are all recorded at every cleaning. Additionally, the technician will be able to e-mail the service report to the customer for their records and the technician notes at the time of maintenance will provide adequate documentation for warranty purposes in the case of filter component failure.

Regardless of the documentation method that your cleaning center uses, make sure that you have access to the records in case of a warranty event. Access to quality products and system maintenance services are key in protecting your investment and revenue; therefore, every technician should be properly trained to diagnose, troubleshoot and maintain your DPF system.

Taking a Holistic Approach

Take a holistic approach to the care of a DPF system. Always use the correct type of engine oil, such as an approved CJ-4 oil, and track your vehicle’s oil consumption. Turbocharger and charge air coolers should be checked regularly. Turbochargers that don’t produce enough air, or have a leaking seal, can lead to oil and soot generation in the exhaust system, and may damage the DPF. Worn fuel injectors may cause engines to lose fuel economy, lead to improper combustion and filter plugging. When troubleshooting DPF issues look at your vehicle as a whole. Your DPF acts in essence like a storage can, it only catches what gets put into the exhaust stream. The key to a health DPF is keeping that exhaust as clean as possible before it gets to the DPF through routine maintenance.

While the DPF industry has evolved over the last decade dramatically, the basic needs for service and maintenance has remained unchanged. Manufacturer approved cleaning methods must still be followed for proper cleanings. Documentation of service and cleaning intervals must be stored for customer records. The overall health of the engine must be kept proper working order. All of these factors contribute to the efficiency and longevity of a DPF system. Accepting sub-standard work or procedures from cleaning technicians on any of these fronts is putting your vehicle at risk of unnecessary downtime and costly repairs. | WA

Mike Callaway is the Communications Director for Diesel Emissions Service (Redding, CA). For more information about the SPN network, DES’s national DPF cleaning network, or FILTERtrak email Mike at [email protected] or call (888) 792-2922.

Note

DES uses FILTERtrak to track cleaning services and to maintain

digital records. Learn more about FILTERtrak in this month’s Breakthroughs & Innovations sectio