Using constructed wetlands to manage the landfill’s leachate, this innovative operation has taken the reigns in finding unique ways to meet their goals.

As the first lined landfill in North Carolina, the New Hanover County Landfill is no stranger to being a unique operation. It sits on 689 acres, 450 consisting of natural wetlands to the north and east—including the Northeast Cape Fear River and Fishing Creek. Opened in 1981, the landfill serves New Hanover County including the City of Wilmington and the beach communities of Wrightsville Beach, Carolina Beach and Kure Beach. The site geography poses challenges many landfills don’t face. Onsite soils consist of coarse grained “beach sand” not conducive for Subtitle D construction requirements regarding the two foot clay layer. As a result, early management instituted the use of double synthetic liner systems in lieu of the clay layer. The liner for the first cell constructed at the site consists of a layer of PVC and one of hypalon. To this day, staff continues to use alternative double synthetic landfill liner designs at the site that exceed Subtitle D requirements. New landfill cells are constructed with double 60 mil HDPE liners, a bottom geosynthetic clay layer (GCL) and composite drainage net layers (CDN) over both the primary and secondary liners. Says Landfill Manager Sam Hawes, “While some might say the site is poorly located for a landfill, we believe the site is an excellent location as extensive natural wetland areas exist between the landfill and adjacent surface waters. If, in the future, any potential stormwater runoff or potential groundwater contamination occurred these natural wetlands would provide excellent buffering and treatment of contaminants prior to reaching surface waters.”

Leachate Management Challenges

In the same way that site geography (onsite soil consisting of beach sand) presents challenges regarding cell construction, it also creates challenges regarding leachate management. Since cover soils consist of coarse grained sand, precipitation readily infiltrates the waste on the landfill instead of being shed as stormwater. As a result, the volume of leachate generated at the site is higher than most other similarly sized facilities. “Our average annual rainfall exceeds 54 inches per year and that can go a lot higher in years we experience direct or indirect effects from hurricanes or tropical storms that ride up the East Coast,” says Hawes. In an effort to shed stormwater better and also extend services not already available to County citizens, a yard waste management program was recently initiated. The yard waste will self-decay to the point where it can be used as daily and intermediate cover on the landfill. The resulting topsoil will not only shed stormwater better but will also reduce erosion issues and reduce the cost to import topsoil.

The facility is also unique in that staff treats landfill leachate onsite with a biological treatment plant prior to NPDES discharge into the Northeast Cape Fear River. “We’re permitted to treat and discharge up to 50,000 gallons/day and do so at a cost less than that to pump and haul to a publicly owned treatment plant.” Although staff does a terrific job at treating the leachate by conventional means they’ve always looked at better more sustainable alternatives.

Constructed Wetlands

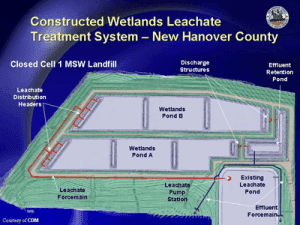

One of the projects that Hawes is most proud of is using constructed wetlands to manage the landfill’s leachate. After extensive research, staff partnered with North Carolina State University and obtained grant funding from the Water Environment Research Foundation and NC Division of Coastal Management (Coastal Area Management Act) to proceed with a pilot research project. The pilot wetlands project ran from 1996 to 1999. The project gained both national and international attention with dignitaries from both Thailand and India visiting the project site seeking low cost, effective treatment options for their countries. Results of the research indicated the wetlands could treat landfill leachate and did an exceptional job treating total nitrogen. So, with positive research results, staff began discussing how to possibly link the constructed wetlands treatment ability with other sustainable practices. Staff desired to eventually eliminate their NPDES discharge so the project was born to link a large scale wetland treatment system with land application onto closed landfill cells to reduce and eventually eliminate surface water discharge. As a side benefit, the treated leachate to be land applied would serve as a low grade liquid fertilizer replacing the need to purchase and apply pelletized fertilizer onto closed landfill cells to maintain vegetation cover.

After securing additional grant funding from the North Carolina Clean Water Management Trust Fund, six acres of manmade constructed wetlands were constructed in 2002. “It’s been a great project. It has allowed us to reduce our permitted discharge by about 40 percent. As we close more landfill space in future years we’ll expand the irrigation system allowing us to get closer to zero discharge, which is our ultimate goal,” says Hawes. “Implementing the use of the constructed wetlands is on the cutting edge of technology and reveals the commitment the County has to manage leachate and solid waste through the use of sustainable practices. While there’s a cost to go the extra mile, there’s also tremendous value.”

The Changing Economy

This same commitment has been deployed across all aspects of the landfill operation to become as effective and efficient as possible. In this challenging economy, that’s more important than ever. One of the ways they’ve done this is to implement the use of GPS on their heavy equipment. The use of GPS allows the operators to see in real time where to cut and fill waste so that all available airspace is used. GPS also makes it easy for the operators to make sure they get enough passes over the waste to get the best compaction possible. Both initiatives drive down the cost to operate as well as extend the life of the site. They’ve also replaced and reconfigured the scale house to process customers more effectively. “To our customers time is money and the quicker we can process them both in and out with 100 percent accuracy makes a big difference regarding customer service,” says Hawes.

Although the total waste stream for the county did drop significantly due to the economy and the downturn in construction, this drop did not impact the total tonnage of waste managed at the landfill. Reason being, the County owned and operated waste-to-energy facility was recently laid-up and the tonnage directed to that facility is now coming to the landfill. Hawes says, “Last year we received 215,000 tons and even though it’s still down from where it was in 2006 we’re beginning to see an uptick.”

He points out that they take safety very seriously as well. Everyone on staff uses two-way radios so they can constantly communicate with each other and weekly safety meetings are held. They are also in the process of creating a safety committee that consists of landfill employees who will assess the site once per month and make any needed recommendations. Regarding heavy equipment training, staff train in-house, but are beginning to look at the use of Caterpillar simulators for additional training. Additionally, a county safety officer conducts all of the annual OSHA required training. “For specialized training, we send our operators, supervisory level and management level staff to SWANA’s landfill operator’s training school and MOLO classes for certification.” Other regulatory permits require additional staff training for spray irrigation, wastewater treatment and drinking water. The County as a whole also has a customer service initiative where employees are required to take at least two customer service training courses each year.

Community Outreach

The New Hanover County Landfill is proud to open its doors for community and educational tours, whether it is for children’s camps, public and private schools or other community groups, such as the League of Women Voters. “We like conducting tours because no one really has any idea of what goes on after the trash is picked up and delivered to a landfill. When they get here they discover there is much more going on than anyone ever really imagines. It’s a great educational tool for us,” says Hawes.

He also points out that the landfill recently started a household hazardous waste program. Hazardous waste is accepted six days per week from citizens. The facility takes everything from fertilizers, pesticides, herbicide and batteries to florescent bulbs, waste oil, SHARPS, antifreeze and paint. “It’s been a real success. In the past, we would just hold an annual household hazardous waste drop off day and we would just be swamped. We knew that people wanted the service for years and now it is available for them to use.” As for some of the household hazardous waste, batteries are recycled, the latex paint is shipped back to the landfill where it is blended with their posi-shell ADC, oil-based paint and other flammable liquids are used for fuel in boilers. Anything that can’t be recycled is properly disposed of by the contractor at a permanent hazardous waste facility.

C&D Processing

Hawes stresses that another accomplishment at the site is their construction, demolition, industrial and commercial waste processing site where recyclable materials are diverted from the landfill. Materials diverted include wood waste, OCC, shingles, carpet, mixed metals and sheetrock. Beginning operations in 2003, equipment used at the site includes a loader and excavator. “It’s a primitive system but its something that we’ve been adding to slowly over time to pull commodities from the waste and we’re hoping in the future that we can expand that operation by adding additional staff to sort and equipment to sort with—right now it is a two-man, manual operation,” Says Hawes “If you look at our waste stream, there’s a lot more material that could be diverted from the landfill.” Last year we diverted about 6,000 tons.

Wood waste is ground up and marketed as boiler fuel, the sheet rock is picked up by a composter, the concrete is used onsite for roadways, shingles are ground for use in asphalt for roads, mixed metals are recycled at one of several local metal recyclers, carpet is collected from a local carpet recycler, and OCC is transported to the County recycling operation where it is baled and marketed. Hawes believes there is at least 50,000 additional tons of waste per year they could remove from the waste stream if the right assets were in place. “We’re not solely looking at it from a revenue perspective, but also as a way to extend the life of the landfill and reducing the wear and tear on our equipment.”

Long-Term Goals

Hawes says that the long-term plans for the site include conversion to a County park with an environmental education center. “The location of our site lends itself to that because we are bordered by natural wetlands and the river. One day we are going to have public canoe launches, hiking trails and observation points. We have a lot of wildlife out here as well—eagles, deer, bobcats, rattlesnakes, bears, etc.—and we have a threatened plant species on our property called the Big Three Awngrass. It’s an arid grass that thrives in disturbed areas. We plan to create habitat restoration areas on our North property for the plant to grow on and plan to leave in place un-disturbed habitat buffers along the perimeter of the site.”

Leachate treatment, natural wetland ecosystems and the threatened plant species will all be included as part of future environmental education efforts. “There is a lot of educational opportunity on the site,” says Hawes. “We are at a point where we are close to reaching capacity on our north property and we will soon be moving onto our south property which is in the permitting phase now. Once we move onto the south property, we will begin to restore habitat for the threatened plant species and also begin, in phases, development of the canoe launches and hiking trails. As technology continues to evolve in the waste industry, I believe we’re going to see less reliance on landfills and more recycling and a move towards more waste-to-energy applications; we are doing our part to take steps towards that transition now.”

For more information, contact Sam Hawes at (910) 798-4454 or e-mail [email protected].