The right engineering approach is critical to optimizing a fabric building for your application.

By Jeff Williams and Scott Jones

Nobody enjoys being forced into a decision. We usually like to consider our options, and the best option of all (of course) is getting something exactly the way we like it.

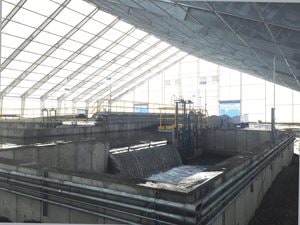

Photos courtesy of Legacy Building Solutions.

Eating at a restaurant is a perfect example. While most menus will have a wide selection of great entrée choices, many of us may prefer to make some tweaks to the standard recipe—wheat instead of white, grilled rather than fried, hold the mayo, etc. Whether it is fast food or fine dining, about the only significant obstacle to customizing an order is poor communication. And if the waiter or cook gets it wrong, rectifying the situation may cost you a few minutes, but nothing more.

The stakes are much higher when it comes to planning and executing a new building project like a transfer station or recycling facility. Finding the right solution on the front end is not the only critical step in the process, but it may very well be the most important one, as reversing that decision is not nearly as easy as yelling back to the kitchen for a re-do.

Fabric membrane structures have proven to be a reliable, cost-effective building choice for waste applications. But for decades, the purchase of a fabric building was always an “off the menu” selection—standard pre-engineered sizes were available, and users picked whatever option most closely suited their needs and budget.

Over the years, leading fabric building manufacturers have made strides to elevate their engineering, putting them more in line with conventional architecture. In contrast to the traditional fabric structure approach, these engineering upgrades are focused on optimization—in other words, specifically matching the building design to all aspects of the intended application.

Optimizing Dimensions

Optimization can be defined in a variety of ways within the context of construction. For fabric buildings, the first and most obvious step toward optimizing a design is providing precise dimensions.

With an older style fabric structure, manufacturers would look at the minimum length and width required by the user, and then offer the smallest size from their existing pre-engineered stock that could account for those dimensions. It got the job done, but often resulted in less than an optimal solution.

Addressing the need to meet more precise building specifications, rigid-frame engineering was introduced to the fabric building market several years ago. Prior to this, the industry had been almost exclusively relying on pre-engineered, standard-size designs that used hollow-tube, open web truss framing.

Rigid-frame design, by contrast, uses structural steel I-beams found in conventional building projects. It also allows the engineering flexibility to quickly provide a custom design from scratch, as the exact length, width and height of a building can be specified down to the inch. Offset peaks, variable column heights, and other unique layouts are also possible. In a nutshell, this technique allows any building to be optimized for its specific use.

Loads of Usability

Beyond building dimensions, rigid-frame design also simplifies the process of accommodating any collateral loads that the building frame must support. Lighting and fire suppression systems are common hanging loads for buildings, as are overhead cranes and conveyors.

Using finite element analysis software, engineers can modify and optimize each individual steel beam based on the actual loads that will be on it, rather than over-engineering an entire building frame to account for those factors.

Structural steel framing also provides the advantage of straight sidewalls. This may seem like a no-brainer when considering the optimization of building square footage, but the fact is the majority of traditional fabric structure designs have radiused, or curved, sidewalls.

Building operators who plan to place material or construct anything directly along a straight sidewall can do so while also specifying the exact vertical clearance needed. For example, a building user who wants a pallet rack for storage can place it flush against a straight sidewall. But if that sidewall is curved, the same rack needs to be moved in from the wall to fit vertically, leaving wasted square footage behind it.

Eye Toward the Future

While immediate space use is obviously a critical component of building architecture—and a big factor when choosing between custom and pre-engineered designs—there are numerous long-term considerations to keep in mind as well.

Optimization of the building profile also helps ensure operational cost savings in a variety of ways. An oversized, pre-engineered building will naturally require more lighting, along with a larger HVAC system to heat and cool the space. Building applications requiring insulation could incur more costs as well. Minimizing these kinds of expenses through a more energy-efficient design can have a significant financial impact over the lifecycle of a building.

Another issue to consider is current investment versus future need. It is no secret that many industries have been trending toward the use of alternative energy sources. Some facilities have even been designed to operate off-the-grid by using solar panels. In other cases, solar panels were not feasible in the original budget, but the building frames were still proactively engineered to carry that type of load during a potential retrofit in the future.

Water Management

Building style and shape obviously can have a big impact on the interior functionality of a fabric structure, but those characteristics should also be closely examined when it comes to managing water, ice and snow.

Whether it is a classic half-circle “hoop” style structure or a building with more subtle curvature to the sidewalls, traditional fabric buildings all experience the same problem of snow, water and ice all shedding right down to the base of the structure.

Unless users have an excellent drainage system or a site that significantly slopes away from the edge of the building, they are likely to be fighting water infiltration issues and possibly foundation cracking for as long as they have the building. In extreme cases, poorly tuned ventilation can eventually cause leakage issues on the interior of the building.

By contrast, the more conventional building approach of rigid-frame design allows for an 18-inch overhang on the eaves on the structure. From there, users can specify any water and ice management features they need. Icebreakers can be added to meet safety requirements related to sidewall height. Gutters and downspouts can be included to capture and jettison water away from the structure, providing optimal environmental conditions for the building exterior and surrounding site.

Project Management

The actual end-to-end, start-to-finish construction process of a fabric building also widely varies from one supplier to the next … and there can be dramatic timeline or procedural differences at every step along the way.

Although it sounds counterintuitive, it could take several weeks or even months just to finalize the design of a pre-engineered building, simply because they are not as adaptable to even small levels of customization. Meanwhile, the engineering for a fully customized rigid-frame design can be rendered in a matter of days.

From there, many fabric structure manufacturers rely on third-party suppliers for building components. However, some companies have invested in their own onsite facilities to manufacture fabric panels or produce steel frames and components, allowing them to maintain a higher level of precision and quality control over their product.

Delivery methods among suppliers have also wildly differed over the years. Common practice for many manufacturers is to provide a supervisor to oversee installation, leaving the customer to arrange for hiring their own subcontractors to address the various aspects of construction. Some manufacturers have found that a more advantageous approach is to provide their own in-house professional installation crews who are specifically trained to erect fabric structures, helping to ensure both a fast turnaround and an optimal final result.

Some companies provide a one-stop shop for all of these services, from initial design to final turnkey and handover. With the capability to fulfill any and all roles—including design, manufacturing, general contracting, construction management and installation—suppliers can more easily adapt to potential issues throughout the project.

There are also multiple benefits from a customer standpoint to going through an end-to-end process with a single company. Having the building manufacturer involved in every phase provides generally greater opportunity to recognize opportunities for cost savings or improvements early on. On a very basic level, if issues do arise, the customer knows exactly who is responsible and who to call. And for suppliers who are insurance bondable, customers can go into the process with even greater peace of mind.

Optimized Results

At the end of the day, fabric building optimization is all about somebody fully understanding what the application is and making the adjustments to ensure the structure meets all necessary requirements. Find the right solution and right people to lead you down that path, and you can feel confident of receiving the best possible outcome.

Jeff Williams is the Vice President of Sales for Legacy Building Solutions (South Haven, MN). He can be reached at [email protected].

Scott Jones is the Construction Manager with Legacy Building Solutions. He can be reached at [email protected].

For more information, visit www.legacybuildingsolutions.com.

You may also like:

Introducing Conveyors Systems into Fabric Structures