Allowing your team some time to learn all the rules and review your plan often will ensure that you are managing your transportation process and it’s not managing you.

Julie Mink

If you’re in the logistics role within your waste company, your responsibility to understand transportation management can be quite cumbersome. We define the statement “Transportation Management” as the segment of logistics and transport options (truck, rail and barge) required to get your product from its source to its final destination. On the surface, the logistics chain may seem simple; however, there is a significant amount of detail required in arranging, preparing, releasing, tracking, resolving and delivering your shipment which requires forward thinking (and frequent quick thinking) to be successful. For waste shipments, the process can be as simple as a one-time load and transfer to a more complex move complete with several moves, transloading, sorting, packaging, re-loading, moving, delivering and finally unloading.

Considering the variables involved in our definition of “Transportation Management”, your responsibilities generally encompass:

- Match up transport modes and rates with routes and service for the best combination of price and delivery options

- Match up rail equipment availability, type and capability with product load and unload requirements

- Consider all available modes of transportation for product movement in context of timing, cost and delivery capability

- Optimize the use of your infrastructure to seamlessly move product into and out of production

- Source rail equipment, reconfiguring rail yards, optimize multiple transport options in a production plant setting and understanding the flow of product

This month we take a look at the basics of shipping by rail and examine several questions that are frequently asked during day-to-day operations. Whether you’re new to shipping by rail or a seasoned pro, we believe these questions can help you work through the shipping waste-by-rail more efficiently.

#1: I’ve Been Shipping via Truck, Should I Consider Shipping via Rail?

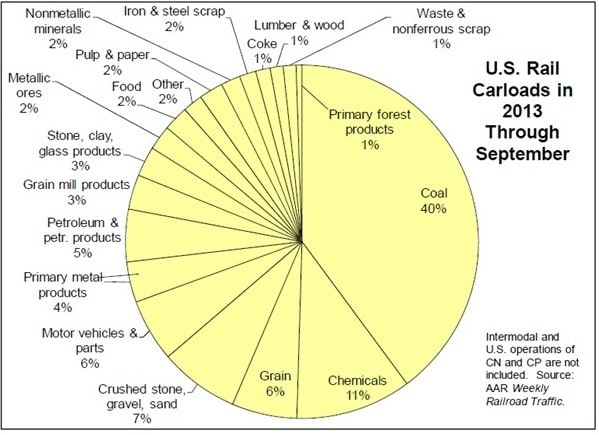

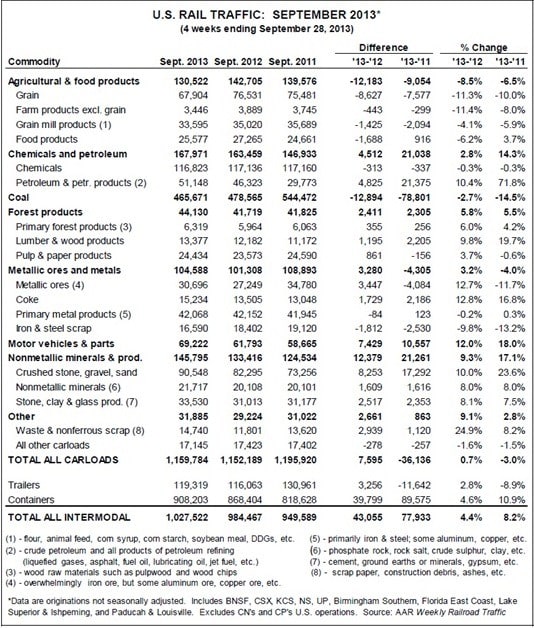

The decision to transition from shipping via truck to shipping via rail can often be a daunting one. If you’re new to rail, allow yourself and your team time to learn about the overall rail environment and infrastructure. As you start your journey, realize that as of September 2013, only 1 percent of all U.S. rail carloads were waste and nonferrous scrap carloads (see Graph 1). For September 2013, this equated to 14,740 waste and nonferrous scrap versus all 1,159,784 carloads (see Graph 2), so getting the attention of a regional and local rail carrier (also referred to as a Shortline railroad) may be easier than getting the attention of the large national carriers (also referred to as Class I railroads).

Hiring a qualified rail transportation consultant and having data prepared before meeting with rail carrier(s) representatives will help you support your case and potentially win a spot in the train. Contrary to most business relationships where you’re in the customer role, your conversation with rail carriers will generally start with your pitch as to why the rail carrier should select your shipments for service—not other way around. If you enter the initial phase with this point in mind, business dealings generally run smoother. Once you meet with the rail carrier customer service representative, you will be able to realize the costs and benefits of shipping by rail. Make sure you’re prepared by asking yourself what your anticipated daily, weekly, monthly and yearly volumes will be and ensure that your volumes comply with any requirements your rail carrier may have.

You’ll also need to understand the current infrastructure of your loading and unloading facilities to determine what type of railcars you will operate and if you want to lay down track onsite or if you’ll opt for use of a nearby transloading facility which will require you to truck waste from the nearby rail site to the final destination.

#2: What Type of Equipment Options Will I Have?

Once you have established your yearly volume forecast and how you will load and unload, you’ll need to understand the density of your product in terms of weight (pounds per cubic foot) so that you can calculate which size and type of railcar you should use.

There are various types of railcars available to support your specific needs and determining which equipment type matches your needs is critical in ensuring that your rail shipments are economical. Customers with dense and light loads (let’s use un-compacted MSW with a weight of approximately 8 pounds per cubic foot as an example) will require railcars with a high cubic foot capacity as the product will fill the railcar to the top before it meets the load limit of the railcar. This is referred to as “cubing out before weighing out.” A customer moving a denser and heavier load (let’s use wet sludge for this example at approximately 45 pounds per cubic foot) will want to consider railcars with a lower cubic foot capacity as their load will typically meet the load limit of the railcar before the car is full to the top. This principle is referred to as “weighing out before cubing out”.

Determining how you’ll load the product into the car (will you bundle or package your product, load it into containers for flat car service or will it be loaded and unloaded loosely) will help you determine which car type is right for you. Depending on your capacity needs and total count of railcars required you may be flexible enough to work with the railroad for use of their system provided equipment. In the event the railroad requires that you acquire your own fleet of equipment or in the event you desire a more predictable source of equipment, acquiring railcars for private use (leased or owned) might make sense for your company. Exploring the costs and benefits of each during both the startup phase as well as throughout the upcoming years will ensure that your transportation costs stay in check.

#3: What Rules Do I Need to Follow?

When you decide to move via rail, work with a customer service representative or a qualified transportation consultant to identify railroad rules that apply to you. Each railroad has designed and implemented rules and regulations for transporting various products on their rail line. These “tariffs” as they are called provide guidance to the shipper in understanding the railroads protocol for shipping the product safely. You’ll first need to identify your products specific Standard Transportation Commodity Code (STCC) to ensure that you’re applying the correct tariff. It is also important to understand that your individual freight rate will also vary based on this STCC. In addition, you’ll need to obtain a copy of open top loading rules from the Association of American Railroads (AAR) to ensure that you are loading your railcars correctly. The consequence of shipping an overloaded railcar that is not in compliance with current open top loading rules can result in the railroad stopping your railcar(s) in transit and requiring you to bring the load into compliance where it sits. This can turn into a very costly chore as initiating a crew to fix the load(s) and possibly transloading part of the load into trucks can eat up precious time and resources and unwillingly increase your freight expenses.

As you work with the railroad to establish a contract for rail service, be sure to address demurrage/private railcars storage issues before they arise so you can adequately plan for them before they occur. Be sure to define free days versus credit days as well. Rail carriers may charge daily demurrage fees for railroad owned railcars which sit loaded or unloaded on their property too long and rail carriers may charge demurrage fees for private railcars that sit on their line for a time longer than what is allowed by contract (also referred to as Private Car Storage). Rail carriers can also grant you a “free day” or a “credit” which is typically defined as a 24 hour grace period for say a particular day of the week/weekend or for a holiday. Knowing where the boundaries lay will help both your budget and your plan.

#4: I’ve Decided to Use Private Railcars Rather than Relying on Railroad Supplied Equipment. Now What?

Establishing a private railcar fleet can be a large undertaking but the result is usually quite rewarding as operating a private railcar fleet generally allows the shippers to have a great amount of control in their logistics chain. Being able to spot, load and ship a car within the same 24-hour period is generally more desirable than requesting a car from the railroad and waiting several days or more for the car to be delivered. Contrastingly, operating and managing private equipment can easily become a full time job.

Responsibilities to operating a private fleet will vary depending on if you buy or lease your cars but in general, some items to put on your to do list include:

- Register a private railcar mark with Railinc

- File paperwork with the Surface Transportation Board (STB)

- Submit an OT-5 application (completed through Railinc) to run the equipment on the rail carriers line

- Define a process in the event a car is bad ordered and needs repairs

- Establish a preventative maintenance program

#5: What Can I Do with Idle Private Equipment?

From time to time, you may find that volumes you predicted have dropped (either expectedly or unexpectedly) and your plant may be stuck with excess cars. This is a pretty common occurrence so solutions are not too difficult to identify. A transportation specialist can assist you with this process and you may even find that your competitors have advice and even solutions to offer.

Railcar storage facilities boom when the economy is in transition or a lull and chances are good that you’ll be able to location a railcar storage yard close to your facility. When interviewing potential storage facilities, look for storage options where daily rates and switching fees (both in and out of the facility) are fair and reasonable. Identify if the storage facility requires that you move cars out in the order in which they were placed (typically this is a last in, first out arrangement) or if you have the option to cherry pick (hand select which railcars you want to move first) and identify if the railcar storage facility has access to a repair and maintenance crew as you may find that time spent in the storage yard is a great time to have needed repairs, maintenance or upgrades completed.

Another option for your idle assets is to offer the cars to another rail shipper within your industry for short time use under a lease or sublease arrangement. This is typically a very good scenario as long as you the product shipped is similar in nature to your own and initiating the cars into this alternative service does not cause you any undue stress. Ensure that you have a valid contract in place that outlines the responsibilities of both parties.

If you expect a long term decline in volume, selling your equipment or working to lease your equipment out may be a better alternative. The location of your equipment, condition of your fleet and demand in the market place will all dictate the final price but allow your current book value be a starting guide. You will generally find that pricing of your equipment will ebb and flow right along with the economy and you might just find that you can turn a profit on your owned or leased assets.

By planning your transportation management process in advance as well as by having the right resources in your corner, your logistics chains should run quite smoothly. Allow your team some time to learn all the rules and review your plan often to ensure that you are managing your transportation process and it’s not managing you!

Julie Mink is Vice President of Tealinc, Ltd. (Forsyth, MT) and is located in the Elizabeth, CO office. Julie’s career includes positions as Vice President Marketing and Administration and Manager Value Creation. Julie’s tenor at Tealinc has spanned strategic and financial planning, project management, direct customer sales and customer support, development, refinement and installation of the e-commerce program, formulation and execution of marketing strategies and development and refinement of the company’s extensive market database. Julie has eight years of direct experience creating value for Tealinc customers. Julie’s attention to detail and concern for the customer are key assets to Tealinc success. She can be reached at (720) 733-9922 or [email protected].

Graphs courtesy of the Association of American Railroads at www.aar.org.