How today’s leading fleet management solutions are providing the best fleet safety benefits by eliminating the main causes of motor-vehicles accidents and providing fleet managers with the tools to curb unsafe driving habits.

Don Diego Padilla II

Government data clearly indicates that less driver distractions equals less accidents. Statistics

from the U.S. Department of Transportation (DOT) indicate that 3,154 people were killed and more than 424,000 injured because of distracted driving in 2013.1 Nearly 20 percent of all injury crashes in 2010 were reported as distraction-affected crashes.2 The direct and indirect costs of these accidents are huge.

In the vast majority of cases, these incidents are due to driver behavior. All drivers have different tendencies and driving styles, some of which can be risky and downright dangerous. Whether it’s speeding, hard braking, distractions or poor awareness, many accidents could be avoided by curbing risky behaviors and coaching drivers on safer operating practices.

The on-board computer systems (OBCs) available for waste fleets can significantly reduce these risks. These systems increase safety in two ways. First, they reduce driver distractions by streamlining the navigation and service process. Second, they track driver behavior and relay the information to management so that they can address unsafe driving practices.

Driver Tracking and Coaching

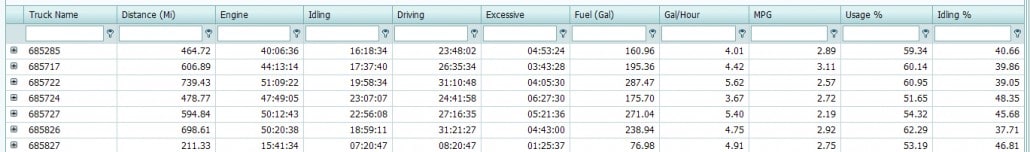

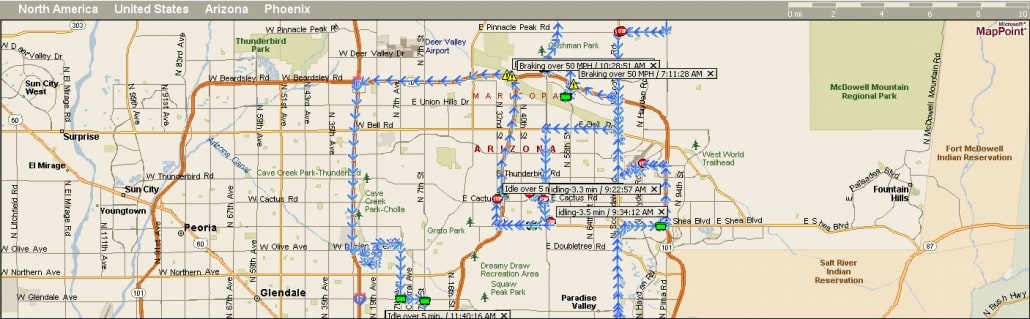

Of all the standard fleet safety components, driver monitoring and the ability to easily score driver behavior are of utmost importance. Scorecards can be a very compelling mode of behavior modification. Automatic and real-time access to driver scoring results provides the information required to give constructive feedback to drivers, reward safe driving behavior and provide the requisite coaching for any unsafe activity. The same system will also actively improve safety through a system of alarms and reports to help eliminate unsafe driver behavior. In-cab alarms will sound to alert drivers of issues such extended idling, high speeds or hard breaking. This will help improve fleet safety in real-time and alert drivers to their mistakes for immediate correction.

The most important part of this process is the coaching. Evaluating drivers offers the best results when used a coaching tool, not a tool for spying on drivers and punishing poor driving habits. Managers should use the information to identify and constructively address the issues to eliminate the unsafe behavior.

Implementing driver scorecards is likely to meet with some resistance from drivers. Real-time monitoring of their every driving action may feel “big brother-like” to some. The key to gaining acceptance is to communicate clearly to drivers exactly what they will be measured and scored upon, how this data will be used, and that it will be universally implemented across all drivers and vehicles. This is in effect will drive a cultural shift toward greater accountability.

Reducing Distractions

Waste fleet drivers have to be multi-taskers. They have to drive the trucks, empty carts and containers, follow routing instructions, interact with dispatch, respond to customer service issues and more—mostly in real-time. On a typical day, a waste collection driver has the potential to be distracted in hundreds of ways. Eliminating or seriously reducing the risk of distraction is of utmost importance. Virtually all of this can be easily eliminated or radically reduced by deploying the right onboard computing system.

New and advanced touchscreen displays make bilateral communications between drivers and dispatch easy and intuitive. These smart displays typically provide a single point of interface for the driver, truck, back office and all communications. A touchscreen display allows for real-time video and audio functionality, and flexible interfaces ensure easy interaction with the control system. In a recent South African study (2008-2014), trucks with smart displays were found to experience 1.53 accidents per million kilometers, as opposed to the 2.53 accidents experienced by baseline trucks.3

Driver direction tools automatically provide directions to a driver’s next designated stop and can also re-calculate routes when a driver deviates from the planned route or makes an out-of-sequence manual stop. Drivers are easily directed to their next location with little to no distractions. In addition to the driver direction tools, more and more waste carts and containers now come with RFID tags installed that automatically track individual stops. For a typical commercial route of about 120 stops, usually 95 percent can be automated. This means that dispatch will know automatically and in real-time when a lift is done, how much it weighs and so forth. With these tools, no manual input will be required from the driver and they will be able to focus on driving safely.

Don Diego Padilla II is Vice President Sales, North America for Fleetmind Solutions Inc.

He is a long-time business development leader with a proven track record of accomplishment in the waste and recycling industry sector. For over 25 years, Don Diego has built his expertise and understanding of the waste management sector and its fleet management issues to better address his client’s needs and help shape solutions to positively impact their businesses. Responsible for sales leadership and driving market penetration at FleetMind, he can be reached at (888) 639-1666, ext. 351 or via e-mail at [email protected].

Notes

- Facts and Statistics. (2014, January 1). Retrieved April 28, 2015.

- Department of Transportation. 2012. What is Distracted Driving. https://www.nhtsa.gov/risky-driving/distracted-driving.

- KIENHÖFER, F., & NORDENGEN, P. (2015, March 3). Smart trucks know how to get themselves in line. Retrieved April 24, 2015.

Additional Resource

https://www.moneysavingpro.com/smartphones/texting-and-driving/