From clean source separated organics to packaged food materials, Waste Management’s CORe® process can manage higher levels of contaminated food waste, providing customers with a more practical and economical way of managing a wider variety of food waste generated at their workplace. Arielle Bernard, CORe®’s Sale Support Manager for Waste Management Greater Mid-Atlantic, discusses the concept, operation, benefits and its most recent facility.

What is a Waste Management CORe facility? Waste Management’s (WM) patented CORe® process is an innovative solution that recycles pre- and post-consumer food waste into EBS®, a high-quality engineered bioslurry product of organic feedstock used for co-digestion in municipal wastewater treatment plant anaerobic digestors. Co-digestion is a proven solution for large scale urban food waste management and is much more efficient at recovering the energy in food waste than incineration or landfilling with gas collection. For this reason, WM has identified the importance of building CORe® facilities in densely populated cities including Los Angeles, New York City and Boston. In Spring 2018, WM opened its fourth CORe® food waste processing facility in Elizabeth, NJ and entered a public/private partnership with the publicly-owned regional wastewater treatment facility, Rahway Valley Sewerage Authority (RVSA). The Elizabeth CORe® facility is permitted to receive and process 500 tons per day of food waste as well as 60,000 gallons of liquid organic material per day.

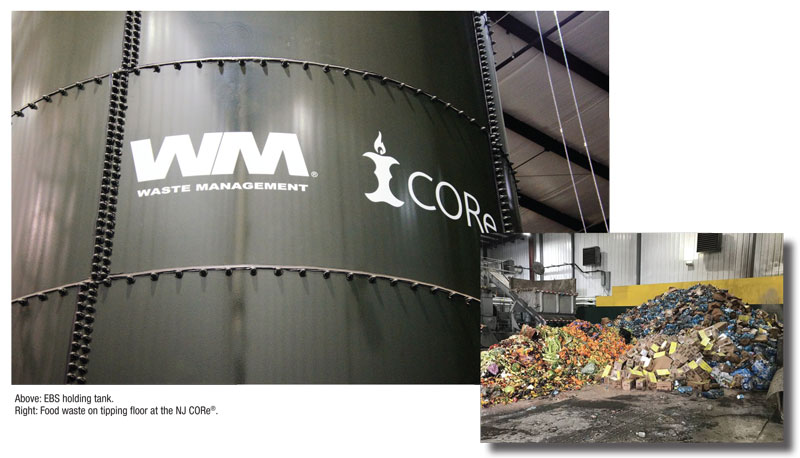

The CORe® facility has the capability to process a wide range of organic material, varying from clean source separated organics (fruit, vegetables, meats, dairy and bakery goods) all the way to packaged food materials (pallets of food, product in cardboard boxes, food and beverage liquids in plastic bottles and cans). Packaged food material typically has not been captured in the past partly due to the fact that it is too labor intensive to manually separate the organic material from the packaging. Now with the CORe® process, WM is able to tap into complex, challenging waste streams and recycle food waste, without removing its retail packing through our multi-step proprietary process. With the CORe® process, WM can extract the residual fraction while capturing the organic material to create the final EBS® product. The EBS® product is a high quality, consistent slurry with more than 99 percent of the physical contaminants found in urban food waste removed.

Once the EBS® product is produced at Elizabeth’s WM CORe® facility, it is transported to RVSA, which is located just six miles from the site where it is introduced into their anaerobic digestors to increase the production of biogas. Currently, RVSA has reported an increase of 100 percent in methane gas production, which is being used onsite to create renewable, sustainable energy for use in its 1.5 MW cogenerators. Additionally, RVSA and WM are investigating alternative uses for the excess biogas created. This truly is a sustainable, cutting-edge solution in the recycling industry that benefits all parties involved.

How is a CORe facility different than other food waste recycling facilities? The WM CORe® technology itself has allowed us to expand recycling services by processing more than just clean organic material that has historically been managed through composting processes. WM believes in composting; however, it is often impractical in urban areas where the large properties needed to properly operate a composting facility are either unavailable or prohibitively expensive. WM operates 44 organic recycling and composting facilities in the U.S. and Canada While composting is, and will remain, an effective way to manage clean streams of food waste, the CORe® process can manage higher levels of contaminated food waste. This provides our customers with a more practical and economical way of managing a wider variety of food waste generated at their workplace. CORe® provides a local solution and is able to process and recycle food waste in one to three business days so the turnaround time is fairly quick.

From where is the food waste collected and how is it transported to the facility? Food waste is collected from a wide range of customers, including restaurants, supermarkets, colleges, hospitals and other institutional facilities, manufacturers and corporate cafeterias, as well as generators of contaminated, out-of-date and recalled food that can no longer be consumed.

CORe® allows for innovative transportation options to ensure our ability to collect from customers and aggregate volumes through multiple collection modes. The plant accepts organic material in pallets, WM’s proprietary BulkBins™, 55-gallon drums, tanker trucks, roll-off containers and compactors, totes and more. These collection methods showcase Waste Management of New Jersey’s efforts to provide its customers with innovative and effective ways of managing food waste.

CORe® Process Origins

Waste Management’s CORe® process originated with its beta system in Orange, CA. The company recognized a growing interest for more sustainable solutions for food waste recycling, renewable energy production and greenhouse gas reduction. In 2011, WM implemented its first full scale CORe® system in southern California to validate the production of a high quality, high energy potential fuel source for co-digestion at municipal wastewater treatment plants. Extensive R&D work, led by WM, resulted in a unique food waste recycling approach that met key technical, economic and sustainability objectives. In 2014, in conjunction with the Los Angeles County Sanitary District (LACSD), WM structured a full-scale pilot program for co-digestion of its EBS product, an engineered bioslurry, at the LACSD Carson municipal wastewater treatment plant. The success of WM’s Orange CORe® facility coupled with the co-digestion and renewable energy benefits observed by LACSD supported the launch of the next generation CORe® process in New York City, Boston and Northern New Jersey.

Are there vendor/manufacturer/service partners that WM uses during the process? The EBS® product that is created at our facility is ultimately transported to a local wastewater treatment plant and fed into an anaerobic digestor to create renewable, sustainable energy. WM does contract with vendors to transport the liquified EBS® product using sealed, leak-proof trucks.

The successes achieved at the Northern NJ CORe® since its first years of operations would not have been achievable without the strong relationship WMNJ has established with its project partner at RVSA. An important part of the project that helps make this approach a success, was taking advantage of the existing infrastructure that was already in place at RVSA for anaerobic digestion. Being able to partner with a publicly owned wastewater treatment plant and use their existing systems dramatically helped WMNJ make this facility a reality. The facility employs three operations technicians and a facility manager. As we continue to expand and receive higher volumes, we will eventually need to hire more operators and add an additional shift.

What is the ultimate goal of these CORe facilities? We often say, “Wasted food is wasted energySM”. Simply put, throwing away food is throwing away energy. WM has designed, built and is operating the Northern NJ CORe® facility to compete with traditional disposal options in this market. The reward for customers is the tremendous environmental benefit of recycling their food waste and effectively generating renewable energy. We hope more customers take advantage of this proven, innovative solution so WM can operate the plant at its top capacity and our public private partnership with the Authority allows them to become a net exporter of renewable energy. It doesn’t get any greener than this.

Why are the particular CORe locations chosen? Is there a certain criteria you are looking for? WM is constantly listening to its customers and its communities and looking down the road at the next generation of facilities and services that will manage materials, conserve resources and protect the environment. We heard that more and more of our customers in North Jersey and New York City wanted landfill-free options for their food waste. We also saw that state and municipal governments were moving toward diverting food waste from landfills. As you may know, New Jersey approved a law mandating that high-volume food waste generators divert this material from landfills in certain areas of the state. The law goes into effect in October 2021. For the NJ facility, it helped that we had existing property in Elizabeth, a great working relationship with local officials, and a digestion facility nearby at the Rahway Valley Sewerage Authority plant.

How the CORe® Process Works

• Incoming food waste is received within the enclosed transfer station.

• Food waste is loaded into the CORe® process’s hopper/conveyor.

• Food waste is conveyed into a bioseparator, which separates organic and residual waste.

• Food waste is liquified within the bioseparator to produce a fluidized feedstock.

• The feedstock is pumped into the WM proprietary process to produce the EBS® product.

• The EBS® product is transported via tanker truck to the wastewater treatment plant.

• EBS® is introduced directly into anaerobic digestors for solids destruction, resulting in increased biogas production.

• The biogas collected has several beneficial uses. This includes being used in a wastewater treatment plant’s boilers for heat and other process needs, combustion fuel for electrical cogeneration equipment, or introduced into the natural gas utility distribution system for commercial and residential heating and cooking.

To better understand the CORe® process, view the video: www.youtube.com/watch?v=TP1B3f9FRGw&feature=youtu.be

The Elizabeth CORe® facility was designed to compete with traditional disposal options in the North Jersey-Metro New York market (i.e. landfill or incineration). We do not set a limit to how far out we can accept food waste from. Transportation costs are the typical driver for a customer to decide where/how they will manage their food waste.

Did COVID-19 affect any part of the process this year? If so, how and how did WM’s CORe NJ facility overcome the challenges? COVID-19 did set us back a bit, but fortunately we have remained operational throughout the entire pandemic. At the end of 2019, WMNJ launched an organics toter route to provide service to smaller food waste generators in Union and Essex counties. COVID resulted in the closure of many of these businesses and forced us to suspend this service. We hope to relaunch this service when conditions permit.

What was the community reaction to this type of facility? Did you experience any pushback? If so, how did you deal with it? Given the innovative nature of the project, we needed about three years to complete the local and state permitting process for the Elizabeth site. We are thankful for the great support our project received from our regulators and community supporters.

WMNJ engages with the community by being a member of several local groups, including several Chambers, New Jersey Food Council, Association of New Jersey Recyclers and more. To further our education and outreach efforts, WMNJ has dedicated sales representatives and program managers who are available to ensure the organics recycling program is a success. In the field, the WMNJ team provides businesses with tools including staff training, informational signage and organics recycling guides. WMNJ also leads formal tours of the CORe® facility, with more than 150 tours to date led to involve school groups from elementary through higher education (both domestic and international), political leaders, and other community organizations.

In addition, last year the WMNJ CORe® received the NJDEP Recycling Industry award: www.state.nj.us/dep/newsrel/2019/19_0083.htm

Using the Renewable Energy

The Rahway Valley Sewerage Authority (RVSA) is responsible for processing the EBS material delivered by Waste Management (WM) through their storage tank and, ultimately, through their anaerobic digesters. As part of the ongoing Public Private Partnership, RVSA shares operational data and collaborates with WM regarding the operation of the digesters; however, RVSA maintains responsibility for the maintenance and operations of all processes within the plant.

The renewable energy, in the form of biogas, is cleaned using RVSA’s Gas Treatment System and is used as fuel for RVSA’s Cogeneration Facility. Electricity produced in this facility is used internally at the RVSA Treatment Plant. The waste heat from the engines is used to thermally treat the biosolids produced by the digestion process.

During RVSA’s due diligence period around 2013 and 2014, RVSA senior staff met with Jim VanWoert, and John Wohlrab from the Greater Mid-Atlantic team as well as the Corporate Organics development group about the potential for accepting food waste at RVSA. After putting out an RFP in April 2015, the contract was awarded to WM in November 2016. WM customized the Feedstock Receiving and Pumping Station in close collaboration with RVSA, but WM was the sole designer for their Elizabeth CORe® facility. The first delivery of EBS® product from WM was in April 2018.

Since the facility came online, RVSA has regular operations meetings with WM to discuss the status of the deliveries anticipated and to review the health and operation of the digester system. The RVSA continues to maintain and operate all of the equipment relative to this system. John Buonocore, RVSA’S Chief Engineer/Assistant Superintendent and Jim Meehan, RVSA’s Executive Director, have been to many conferences throughout the U.S. presenting the project along with their attorney, Rick Sapir from Hawkins, Delafield, and Wood, who was a critical part of putting the partnership (the first of its kind) together.

As the CORe® facility’s volumes increase, the Authority will move closer to generating all of the energy it needs for its processes and perhaps exporting excess energy into the local distribution system.

Are there any future plans to upgrade/add onto this facility and are there plans to build another CORe® facility in the U.S.? We’ve barely begun scratching the surface of this market and see tremendous future potential for our green food waste option. As more customers send their organic material to CORe®, we will need to expand the facility to accommodate higher volumes of food waste (i.e., additional EBS® storage tanks, add onto the existing conveyors). WM is in talks with several other cities and municipalities who are interested in launching food waste programs, and our Corporate Organics Team is always seeking the next best location for our next CORe® facility. | WA

For more information, contact Arielle Bernard, Waste Management Organics, at (718) 612-5203 or e-mail [email protected].