The future landfill may be a more highly instrumented facility that provides real-time feedback to its operator of its performance and status. This approach could help in reducing the potential for major failures, loss of productivity and loss of life.

By Bruce Clark, PE and Laurel Ureña, EI

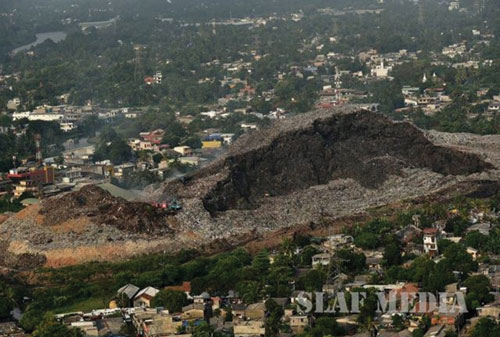

This article is about the future landfill. The future landfill may be a more highly instrumented facility that provides real-time feedback to its operator of its performance and status. This approach could help in reducing the potential for major operational failures including waste slides, long lasting fires and flooded conditions, to name a few, with accompanying loss of productivity, large unplanned expenditures and, in some cases, loss of life. A huge landfill slide in Sri Lanka in 2017 killed more than 30 people (Figure 1).

Many things will be similar to how they are done today, some things may be different. A colleague called it a utopian dream. Maybe so. The typical landfill has not changed much in over 30 years, since the RCRA regulations in the 1980s mandating liners and later landfill bioreactors. Given the multitude of very costly problems like these, that continue to affect landfills, we contend that more consideration should be given to assessing new technologies, or existing technologies used in other industries, that could potentially be beneficially put to use at a landfill.

We present in this article some ideas on what could change, some plausible, maybe some not—at least right now. Modern landfills require many disciplines to collaborate on design, operations and troubleshooting. In the future, more collaborations may be necessary, as the capture of more complex data requires specialists in a vast array of high-tech sensors and large data management, to name a few. So, we are asking for some leeway as we take you into the future.

The “future landfill” could be a highly instrumented machine, monitoring many critical physical parameters. Parameters that could be monitored, and in turn send back valuable data to the operator in real time might include:

Temperature • Leachate Chemistry

Stress and Strain • Sound

Pressure • Vibration

Leachate Level • Video

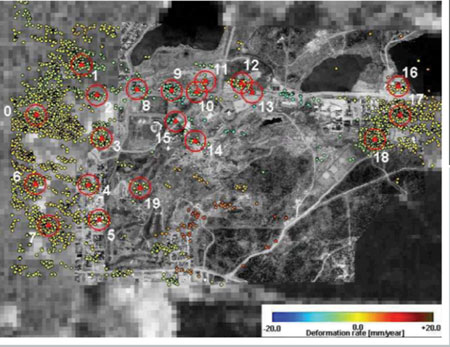

Image courtesy of MDA Corporation, Canada, www.mdacorporation.com.

Monitoring: Potential Advantages

Why go through the trouble and cost with monitoring some or all these parameters? Landfill operators could, over time, reap several tangible benefits including: more effective cell designs, lower O&M costs and reducing large unplanned costs with early intervention into problems potentially keeping them from becoming major issues (elevated temperatures/fire, waste slide, flooding, etc.). The right combination of devices could be used as follows:

• Temperature. Could we sense a deep-seated fire that could threaten the liner? A combination of certain gases, by-products in the gas collection system, smoke, cracks and temperatures above a certain range can suggest a fire or elevated temperature event is present.

• Stress and Strain. What are the real stresses from the waste pile on the leachate collection pipes, and on the liner? Are the pipes and/or liner experiencing differential settlement or over-stress?

• More effective leachate collection systems. Pipe spacing and bottom slope are largely based on empirical equations that are validated over time based on real world experiences. Bottom slopes can change over time affecting efficient collection of leachate.

• Depth of leachate in key zones. What is the depth of leachate? Regulations limit the depth of leachate to 12 inches over the liner, excluding in sumps. Is a cell flooding? Is the leachate at a depth that could overtop a perimeter dike?

• Leachate chemistry. Does the leachate have characteristics that form chemical precipitates or induce biological clogging mechanisms?

• Sound. What could “listening” to the inside of a landfill tell us and help us understand? A landfill is a “living,” dynamic creation, inhaling, exhaling, growing, consolidating, evolving gases, etc. These all may have distinct “sounds”. We would have to learn what frequencies to monitor that could warn of a problem, otherwise we might get a cacophony of meaningless noise.

• Vibration. Landfills are sometimes built in seismic zones. The USGS has its seismic station network. But what about having a mini-seismic station right at the landfill? What if the USGS station is hundreds of miles away? We could measure the actual shock that the landfill experienced and then dictate specific follow-up inspections and geotechnical analyses and/or remedial actions.

• Gases. Monitor combustible and toxic gas appearance (i.e., hydrogen sulfide) and concentrations in the leachate collection system. The safety of personnel in excavations where the leachate pipes are exposed could be increased. Carbon monoxide is emitted when there is a landfill fire.

• Video. High resolution mini cameras are not new. Sewer cleaning companies have camera units that fit through 1-inch diameter pipes. But in addition to required five-year video inspections, why not build in permanent camera install features in key locations, like the leachate collection pipe/header, in sumps, in leak detection zones to monitor conditions?

Waste Strain, Vibration and Sound?

Waste fill stability can be challenging with increasing height of the landfill coupled with the possible inclusion of low strength sediments and biosolid wastes, stratified layers of plastic waste, multiple wet years of above average rainfall, and even founding parts of the landfill on clayey soil that provides a possible slip plane. Landfill waste slides are not very common; however, they still continue to occur. Most in the U.S. do not result in deaths but some do.

What is needed is a reliable way to alert operators of an impending waste slide, that with timely evasive action, might help save lives, reduce loss of revenue, reduce incurring major extra costs and incurring significant fines. This is where sensors that can monitor strain, pressure and vibration could be useful. Even a “modest” waste slide of 10 acres, 35 feet thick weighs more than 400,000 tons. If something that massive is starting to move, you would think we could detect that with the right technology and instrumentation.

ertainly, other visible signs such as surface cracks, change in leachate flow, etc. can be precursors and have been important in reacting to some past slides. However, a technology that could help us better predict a slide before these other signs materialize could be critical to increasing safety and reduce property damage. Automated Motorized Total Stations (AMTS) may work in some applications, but may not if the reflecting marker stations are not in line of sight. If line of site is a problem, say at a very large landfill, a new technology described in the following could be ready soon for landfill use.

Some pipeline and mining companies use technology, called interferometric synthetic aperture radar (InSAR) that combines satellite-based radar images of the ground surface coupled with ground-based sensors to monitor gradual ground movement as a result of forming landslides. They can detect movement of a few millimeters a month. A time series is used over many months or years to show changes in ground movement over time (Figure 2, page 34). It might not be cost-effective today for even a large regional landfill, but the pace at which sophisticated technology, once reserved for space programs, is being commercialized, that cost could be reduced dramatically in a few years and be within reach of many large landfill operators.

These miniaturized sensors ideally would be embedded in the landfill during new cell construction in strategic locations where analysis indicate they could be an early warning and detect significant changes. There also are miniaturized sensors/ seismometers that, if a new cell is many years off, could potentially be placed at the top and bottom around the waste perimeter and monitor vibrations. Remote sensing systems would have to be adjusted/compensated for the “normal” and beneficial consolidation that takes place in a landfill.

Scientists monitor the “sound” of geologic faults grinding past each other in trying to predict changes that could mean an impending earthquake. Does 400,000+ tons of waste ever-so-slowly creeping along make any distinct sound? Could we learn with the right instrumentation and testing what those warning sounds might be? Is there a change in strain and sound that may occur when a waste slide is imminent? If we could understand and differentiate between a problem sound and a “normal” sound, could we potentially prevent huge and costly slides?

What about the performance of the leachate collection system? Is the sound different with leachate flowing normally through pipes versus pipes that are accumulating sand and/or are experiencing chemical or biological clogging?

Leachate Chemistry

Leachate chemistry is another topic that could potentially benefit from advanced sensing devices. Leachate can have all kinds of undesirable characteristics including, scale forming, low pH and corrosivity, that can quickly clog and destroy pipes, pumps, valves, treatment devices and ancillary equipment, and upset biological treatment processes. Leachate characteristics are mostly formed once liquid has drained through the waste.

What if we could detect this chemistry early in the process, in the leachate collection zone or in the collection sumps? Perhaps permanent injection tubes could be pre-installed in the sumps or even in the collection pipes during new construction. These could be used to inject treatment chemicals to correct or stabilize undesirable leachate quality prior to it getting into and damaging the downstream landfill leachate equipment.

Liquid Pressure

Saturation of parts of landfills and the buildup of liquid depth greater than 12 inches over the liner is an ongoing problem for some landfills. Saturation has resulted in waste slides and overtopping of perimeter containment berms at landfills, to name a few very costly issues that also attracted unwanted regulatory scrutiny. Once waste is in place, it is costly and difficult to install liquid level measurement equipment. Simple piezometers and vibrating wire piezometers installed through the waste may be subject to damage as the waste consolidated and exerted side force from increases in waste load.

A sealed pressure sensor that installs on top of the liner in a protective conduit or box that allows contact with the liquid and cabling back to a monitor outside the cell may be an alternative solution (Figure 3). Installing pressure sensors during new construction allows them to be placed in strategic areas and at or on the bottom liner at surveyed reference points. This requires a pressure sensor that could be installed on the liner.

Temperature/Gases

Temperature in a landfill can vary considerably due to moisture, waste types, air leakage and vacuum created from gas collection systems to name a few reasons. Certain biological and chemical reactions can result in elevated temperature in some landfills. Some landfills with elevated temperature are not experiencing a fire and some may have a fire. Gas composition will change if there is a fire. Carbon monoxide is produced, gaseous by products of some wastes may be generated. The ratio of carbon dioxide and methane ratio changes.

The point here is that it would be useful to know whether the bottom liner and/or leachate collection pipes are at risk from a potentially deep-seated fire or elevated temperature condition. Although waste is a good heat insulator, the long-term strength properties of HDPE pipe are significantly affected by elevated temperature. Sensors embedded on or near the liner protective layer and collection pipes could potentially be used to monitor temperature and gas composition changes that could signal a developing and advancing elevated temperature event. Response actions could be initiated to try and limit adverse impacts including costly, risky and hazardous deep waste excavations.

Video

Could placing mini video cameras with built-in lighting in certain areas provide more useful information? For example, design in a permanent track system at leachate pump sump tubes where the camera could be installed down into the pump suction tube (without removing the pump) and view leachate coming in through the tube perforations, the turbulence of the leachate at the pump screen, and growth of blockages. The camera could be retrieved and reinstalled at any time. In the same manner, install a permanent camera track system in main leachate gravity flow pipe headers to monitor depth and movement of flow, accumulation of sand, or formation of growths and other blockages.

Image courtesy of PMC Engineering, www.pmc1.com.

Sensors

So, what would some of these sensing devices look like? Some, like strain gages, are smaller than a postage stamp. A strain gage for measuring deformation from forces on a pipe or on the liner is presented in Figure 4. The sensors would have to be designed and constructed to resist the hostile environment of a landfill including: elevated temperature, chemically aggressive liquids, high humidity, external pressure, the possible physical contact of hard, abrasive waste materials and liquid immersion. Devices that do not have to be installed in the waste will have less longevity issues. No doubt these devices might have to come from other industries including, oil and gas, aerospace, deep sea exploration and surely others.

Image courtesy of Tokyo Measuring Lab, https://tml.jp/e/product/strain_gauge.

The specific type of sensor for each application is beyond the generic outline herein of what could be measured. Sensors can have very specific requirements for how the physical variable (such as pressure) is measured including, mounting orientation, temperature corrections, materials of construction and other electrical and electronic system requirements.

Data Management

Data is basically worthless if you cannot manage it. Having all of these sensing and monitoring devices certainly may mean the data collection software, computer management systems and the overall computing power at a landfill or a local office performing the monitoring would have to be upgraded as well.

Possible Disadvantages

Just like any different or new way of doing things, some of this technology just may not work reliably. The bowels of a landfill are a harsh environment. So, some of the technology may need some tweaking to meet the requirements for performing in a landfill for years. Some, maybe all, landfill operators will say that all this will only increase unwanted scrutiny from regulators. We contend that could be a positive, not a negative. How so? We offer that it is better to know a big problem is coming, especially a massive slide, rather than not knowing something costly could be happening and you could have potentially reduced its adverse impact. However, we need reliable data collection and correct interpretation.

Regulatory Aspects

So, engineers could design and instrument a landfill with all manner of sensing devices, but what would the regulators think about it? There is no doubt that new guidelines would have to be jointly developed as these technologies are deployed and we learn to interpret what the data actually means and separate what is a real problem from a normal or even a minor issue.

Many landfills go along, unknown to major problems brewing; those problems could be widespread flooding, a large waste slide, a deep-seated fire, unusual settlement and more. Collecting data that reveals what is happening inside of a landfill is increasing and monitoring the “health” of that environment is proving to be useful. Sensing technologies can allow an operator to be more proactive in continuously monitoring landfill status, and possibly heading off a major failure. Once a failure occurs, major regulatory intervention follows with the possibility of consent orders and fines, environmental mitigation, huge extra costs with loss of productivity, not to mention the financial liability if you are really unfortunate to have loss of life occur with the failure.

Some landfills might agree to be the “guinea pig” with relief from certain regulatory action should a new un-tested sensing device appear to show a “problem”. Pilot scale cells could be constructed in the laboratory to start to get our arms around some basic questions on the functioning of the devices themselves. Do the sensors have to be hard-wired to the surface? This could curtail their life with the consolidation and movement in a normal landfill, literally tearing wiring apart. Could they be made wireless and still be reliable?

Perhaps the devices are installed in small areas of new landfill cells to start, maybe a 1/2 acre, so the cost and data burden is manageable. This problem is not so dissimilar to other landfill technologies that have been investigated in carefully constructed experiments then scaled up to full size systems including; bioreactor cells, special cover systems and double lining systems.

Investing in Better Technology

The future landfill may be a more highly instrumented facility that provides real-time feedback to its operator of its performance and status. This approach could help in reducing the potential for major failures, loss of productivity and revenue, and loss of life. Many of the technologies to accomplish this are already available and being used by other industries. Tweaking of some technologies may be necessary given the very harsh environment inside a landfill and the need to operate reliably for years. Some technologies, especially for detecting ground movement could potentially use available ultra-sensitive (accurate) remote sensing systems. These could be implemented without the need to wait for a new cell expansion and could be deployed on or around an existing landfill.

We may be soon reaching our limits in relying on monitoring of very basic operational parameters for ensuring a landfill remains safe and performing well as it operates and grows over time, and even many decades following closure. The time is coming when many landfills may have to invest in better technology to monitor more of what is going on inside the landfill. | WA

Bruce Clark, PE, is a consulting engineer who has worked with the solid waste industry for more than 30 years. He is a manager in Tampa, FL for Wood Plc and can be reached at (813) 326-3498 or e-mail [email protected],

Laurel Ureña, EI, is principal and owner of Montani Semper Liberi, LLC, an environmental engineering firm in Tampa, FL and can be reached at (813) 699-0493 or e-mail [email protected].