With the challenges the industry faces, including cost, contamination and soft markets, waste conversion technologies can be more ecological, cost-efficient and create more jobs at the local level.

By Robert Redfearn

Now is the time to invest in waste conversion technologies. Burning fossil fuels for energy makes little sense. A 100w light bulb lit 24/7 for a year requires more than 700 pounds of coal to be burned at the power plant. That 700 pounds of coal produces more than 2,000 pounds of CO2 as the carbon combines with oxygen during the combustion process. With the household waste increasing annually, the volume of available space in landfills is reducing and there are also high environmental and monetary costs related to burying trash and maintaining landfills even after they are closed and capped.

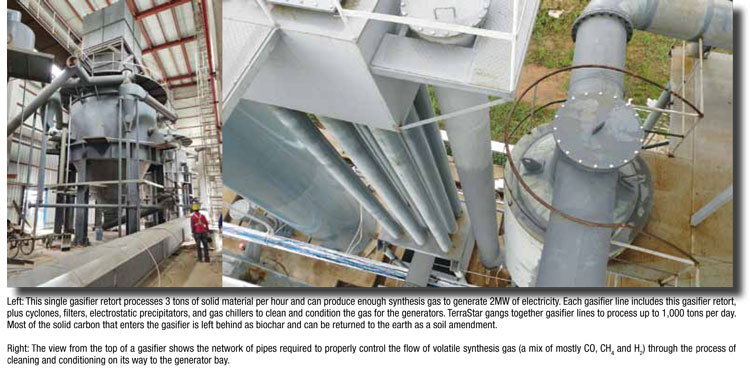

Images courtesy of TerraStar Energy.

Recycling has also becoming a low-viability option now that China has implemented its national SWORD ruling. A lot of time and energy has been spent on source-separation, extra collection, additional line sorting or transportation of the sorted materials to a facility to repurpose the various products. Even at historical highs, the actual amount of garbage being recycled was dismal compared to the actual amount of waste generated.1 Much of what we were sending overseas was being rejected due to “contamination” and in some of those receiving countries, rejected material possibly ended up in the ocean, creating much of the existence of the huge floating plastic islands we read about.

It is these factors that make waste conversion technologies the logical choice as a fuel to produce energy. Converting waste to energy makes sense, because as long as there are people, there will be waste, and garbage has excellent energy value. Incineration (burning) converts all the carbon present to carbon dioxide (CO2). Using gasification and anaerobic digestion technology conserves much of the carbon as solid material that can be put back into the ground, keeping it out of the atmosphere. The bottom line is that waste conversion technologies are more ecological, more cost-efficient and create more jobs at the local level.

The Current Methods of Waste Conversion Technology

Converting waste into energy is more prevalent in other countries than it is here in the U.S. and Canada. This is mostly because energy here has been comparatively inexpensive. Now that we can compete on a capital cost basis with fossil fuels, it should be used more and, ideally, replace the equivalent amount of fossil fuels. All of these waste conversion methods provide “base-load” power (24/7/365) so that they complement other renewable technologies (mostly wind and solar) that are intermittent. Following are the most well-known waste conversion technologies available today.

Incineration

Incineration of waste is the current predominant means of converting waste to energy. Burning garbage creates heat used to generate steam from boilers, which is then used to power turbines to produce electricity. Incineration is the most widely known and used technology to convert MSW to energy. However, it releases a significant amount of greenhouse gas and the plant sizes must be quite large to be economical. Covanta is the largest player in this niche and does over a billion dollars per year in providing this service.

• Pros: Incineration reduces volume and is easily understood. Humans have been burning trash for millennia. It is a highly efficient conversion of waste to energy.

• Cons: Incineration is expensive “per ton”. Large facilities are required for economies of scale, high pressure boilers can be dangerous and CO2 is released into the air.

Gasification

Gasification converts solid materials into volatile gases (mostly CO, CH4 and H2), which can then be combusted in a generator or gas turbines or used in boilers to use with steam turbines. Gasification and anaerobic digestion release far fewer GHGs and leave much of the original carbon behind as a solid, which can be used as soil amendments and fertilizers, thereby sequestering carbon in the ground. Many papers have been written by the U.S. Department of Energy and the Department of Defense recommending the use of gasifiers as a means of converting waste into energy. It is a technology more widely used overseas and just starting to gain traction in North America.

• Pros: Gasification can be easily scaled to match waste supplies and energy demands. It can process almost any carbon-based waste including food, wood, plastic, paper, textiles, etc. Multiple lines can segment one type of waste from another. Modular components speed assembly and commissioning. It is cost competitive with other energy sources including fossil fuels. By-products are carbon rich and can be used for land applications and soil amendments, including as a substrate for fertilizers.

• Cons: Because carbon is not converted to energy, it delivers slightly less energy than burning. Gasification requires a fairly technical system required for operation and gas cleaning, etc.

Anaerobic Digestion

Anaerobic Digestion (AD) uses bacteria to “eat” organic materials. The bacteria creates biogas, which is 50 to 60 percent methane (natural gas), in the process. The biogas can be used to generate electricity or refined to be injected into gas pipelines. Anaerobic Digestion is being used more frequently in the U.S., but still less than abroad. Food waste and animal waste (manure) are being used to produce and capture methane for fuel, while reducing the amount of waste being deposited in landfills and applied to land.

• Pros: It is a fairly simple process, relatively inexpensive and it reduces CO2 in the atmosphere. By-products are excellent soil amendments.

• Cons: Anaerobic Digestion is not able to process wood, paper, plastic, textiles, etc. It is only good for “soft and wet” materials like food and septic waste, and green yard waste.

Syngas and Biogas

A new potential avenue is the creation of liquid fuels from the syngas and biogas. The liquid fuels have a high energy density and can be used in vehicles. After the chemical bonds of the original waste material have been broken, the atoms can be reconfigured using market-proven technologies to create ASTM grade “drop-in” diesel fuel and other liquid fuels and products.

• Pros: Liquid energy is easier to distribute than electrons in many parts of the world.

• Cons: Requires large installations that are quite expensive.

Getting Started

Part of the reason why communities are not using these proven waste conversion technologies may be lack of knowledge. About 12 years ago, people considered making energy from garbage “magic” and it was largely dismissed as a pipe dream. It is more understood now; however, there is a prevailing thought that renewables are more expensive than fossil fuels. That was true before, but it is not anymore. A power plant (AD or gasifier) can be built for the same cost per kW of capacity of natural gas plant, but at a smaller scale … so they can be built almost anywhere. The returns on investment are significant, so attracting investors is not difficult.

Building a network of local entrepreneurs to promote the concept, provide jobs and reduce pollution and greenhouse gases is the best way to ensure these technologies become quickly adopted. We look at working with local partner-developers who can help to develop, then own and operate power plants that intercept waste before it ever gets to the landfill sites. Our business model mimics the franchise models of other industries, where local owner-operators can manage the power plant like a small or medium-sized business, using a standard operating plan (SOP) under a common banner.

Energy here is plentiful and relatively cheap. The U.S. produces approximately 1 ton of trash for each person per year. We estimate that the U.S. market can support at least 1,000 x 20MW power plants, each consuming about a 1,000 tons per day of mixed waste. However, with global warming being a huge discussion point, I think there will be a stampede to this renewable energy fairly soon. It is critical for our environmental safety. | WA

Robert Redfearn is Founder and President of TerraStar Energy, based in North Carolina with offices in Africa and London. Originally from Canada, Redfearn has lived in North Carolina for 25 years. He has 30 years of experience in business in different industries including building/construction, distribution and manufacturing. TerraStar Energy develops and designs power plants that use solid waste and fuel crops (biomass) combined with solar arrays in what they call “Energy Islands”. Their modular systems can be scaled to handle almost any volume of solid waste and other carbon rich feedstocks. TerraStar uses partner-developers in local markets using standardized plant designs and standard operating procedures (SOPs) that mimic the franchise models from other industries. Most of TerraStar’s current projects are in Africa, and they are now targeting the North American market. Rob can be reached at [email protected] or visit www.TerraStarEnergy.com.

Note

1. The total MSW recycled was 67.2 million tons, with paper and paperboard accounting for approximately 66 percent of that amount. Metals comprised about 12 percent, while glass, plastic and wood made up between 4 and 5 percent. www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials#:~:text=Recycling%2FComposting-,Recycling,between%204%20and%205%20percent.

Resources

• Anaerobic Digestion, Gasification, Pyrolysis. Lee G.A. Potts, Biwater Treatment, Lancashire, UK, and Duncan J. Martin, University of Nottingham, UK. www.eolss.net/sample-chapters/C09/E4-13-04-03.pdf

• Development of Environmentally Superior Technologies, Phase I Environmentally Superior Technology Contingent Determinations, High Solids Anaerobic Digester, “ORBIT” Technology. Compiled by: C.M. (Mike) Williams, Agreements Designee. https://projects.ncsu.edu/cals/waste_mgt/smithfield_projects/supersoils2ndgeneration/pdfs/summary.pdf

• “State of the Art of Anaerobic Digestion of Municipal Solid Waste in Europe.” L. De Baere, B. Mattheeuws, International Conference on Solid Waste 2011 Moving Towards Sustainable Resource Management.

• Biogas Markets and Federal Policy. Patrick Serfass, Executive Director, American Biogas Council

• Municipal Solid Waste Trends And Changing Demographics. Nick Chiu, https://seekingalpha.com/article/1081792-municipal-solid-waste-trends-and-changing-demographics

• Estimation of Energy Content of Municipal Solid Waste. July 2004 by Dr. Reinhart. http://msw.cecs.ucf.edu/EnergyProblem.pdf

• “Converting MSW to Biogas”, Waste Advantage Magazine, July 27, 2020. Amit Gami, Business Waste Guru, www.businesswasteguru.co.uk.

• “Recycling Firms Hit by Crushing Economics”, Bob Tita, Wall Street Journal. May 14, 2018.

• Municipal Solid Waste (MSW) to Liquid Fuels Synthesis, Volume 1: Availability of Feedstock and Technology. C Valkenburg, CW Walton, BL Thompson, MA,Gerber, SB Jones, DJ Stevens, December 2008, U.S. Department of Energy.

• An Overview of Advances in Biomass Gasification. Vineet Singh Sikarwar, Ming Zhao, Peter Clough, Joseph Yao, Xia Zhong, Mohammad Zaki Memon, Nilay Shah, Edward J. Anthony, and Paul S. Fennell, Energy and Environmental Science, October 2016

• Comparative Assessment of Gasification and Incineration in Integrated Waste Management Systems. Bary Wilson, Ph.D., EnviroPower Renewable, Inc.

• Shredded Waste Downdraft Gasifier for Overseas Contingency Operations Waste-to-Energy Conversion. SERDP Project WP-2235, Michael Cushman, Infoscitex Corporation, Department of Defense

• Advantages and Efficiency of Gasification. National Energy Technology Laboratory. www.netl.doe.gov/research/coal/energy-systems/gasification/gasifipedia/clean-power

• Gasification of Non-Recycled Plastics from Municipal Solid Waste In the United States. Prepared for: The American Chemistry Council, Prepared by: Gershman, Brickner & Bratton, Inc., August 13, 2013

• “Gasification of Plastic Waste as Waste-to-Energy or Waste-to-Syngas Recovery Route.” Anke Brems, Raf Dewil, Jan Baeyens, Rui Zhang, Natural Science.

• Pyrolysis, Gasification and Plasma. Friends of the Earth, September 2009.