Research before making a decision will result in a perfect pairing between attachment and equipment.

By Francois Martin

Choosing an attachment for a machine is more than just selecting one off the shelf and hoping for the best. The selection process requires attention to detail, along with considerations like application, the machine’s capacity and maintenance of the equipment.

Matching an Attachment

Consider these four things when matching an attachment to a piece of equipment:

1. Application: Is the tool the best fit for the application? For example, if it is a demolition tool, will it be used for primary or secondary demolition? If the attachment is a shear, is it for demolition or scrap applications? Work with the dealer or manufacturer to determine what attachment is best for the desired application.

2. Carrier: Ensure the attachment is suited for the carrier size and weight. Heavier attachments, of course, require larger, heavier carriers.

3. Hydraulic Capacity: Make sure the machine has enough hydraulic capacity to feed the attachment’s requirements. Not enough flow will slow down the tool’s cycle times, while too little pressure results in a lower closing force or less torque, depending on the attachment.

4. Auxiliary Requirements: Is the machine equipped with enough auxiliary hydraulic circuits for the attachment? For example, rotation shears and multi-quick processors require double-acting hydraulic circuits, one circuit for opening and closing the jaw and one for 360-degree rotation. Attachments that do not rotate only require one circuit.

In addition, if the attachment is a shear, it is important that the customer pays close attention to several additional details. For a more accurate power rating, ask the dealer or manufacturer for a force measured in the cutting area. Some manufacturers publish force measured outside of the cutting area.

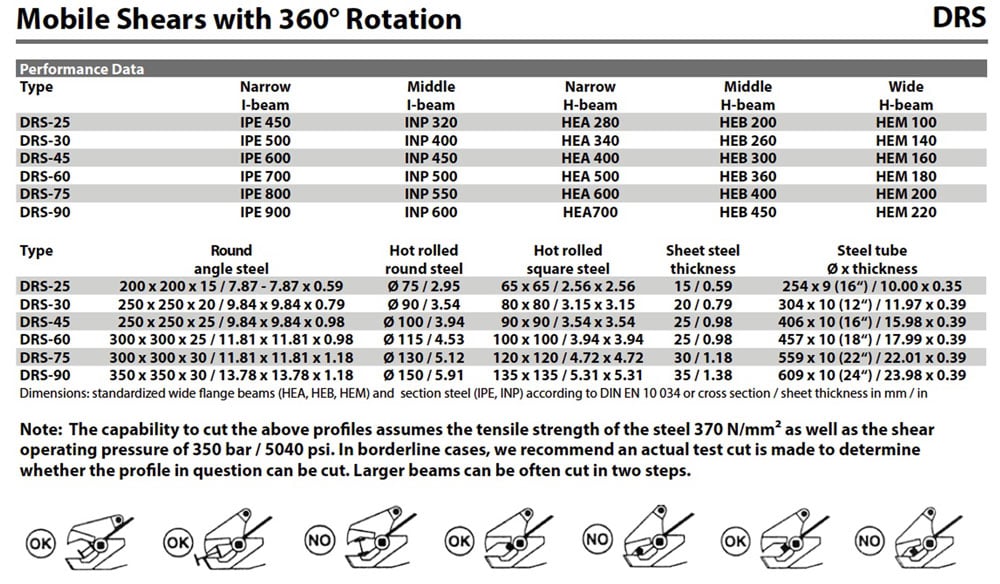

Customers should also pay attention to attachment’s tip force and apex force. Most importantly, they should ask for cutting performances. Look for a manufacturer that has a resource that shows exactly what the shear is and is not capable of cutting. The chart should list profiles and thicknesses that each of the manufacturer’s shear models can cut. If performance data is not available, contact a local dealer.

Customization and Maintenance

Most attachments do not require any machine customization, so long as the carrier is equipped with two double-acting auxiliary hydraulic circuits. Rotating attachments require the two circuits: one for opening and closing the attachment and the second for rotation. Non-rotating attachments, such as some shears and static pulverizers, require only one circuit for opening and closing the attachment. Specialized attachments require some additional customization. If the carrier is not equipped with hydraulic lines to suit all of the Tiltrotator functions, install a proportional valve on the machine and install new joysticks in the cab to give the operator access to all of the attachment’s capabilities. In the case of shears and demolition tools, the dealer will install the attachment after the sale.

Shears and all demolition attachments require daily greasing or after every eight hours of use. Also inspect blades and wear parts daily. Contractors should consult their dealer or the OEM for additional service information specific to their attachment.

Partnering with a manufacturer and doing research before making a decision will result in a perfect pairing between attachment and equipment. | WA

Francois Martin is KINSHOFER North America’s General Manager. KINSHOFER is one of the world’s leading sources of high-quality attachments for excavators and loader cranes. Founded in Germany in 1971, the KINSHOFER Group includes the KINSHOFER, Demarec, RF Systems, Auger Torque and Solesbee’s brands. KINSHOFER offers a wide product range with just about every type of attachment for equipment carriers with and without hydraulics in industries as diverse as scrap, demolition, railway, landscaping, construction, snow clearing, excavating, road building, forestry, tire recycling and biomass. Francois can be reached at (905) 335-2856, e-mail [email protected] or visit www.kinshofer.com.