By tracking tire data and following prescribed air pressure maintenance practices, you can optimize your truck tire investment.

Brian Buckham and Jose Martinez

Are you looking for a sure-fire way to optimize the return on your commercial truck tire investment? Start with tire inflation. Quite simply, maintaining correct inflation pressure is the single most important tire care practice that you can employ. Consistent, correct inflation positively impacts tire wear, casing life and your tire’s overall performance. It can help reduce the amount of fuel your truck uses, and even contribute to a more comfortable ride.

Over-Inflation and Under-Inflation

The benefits of checking—and if needed, adjusting—your tires’ air pressure levels more than make up for the time and effort that this practice requires. Both over-inflation and under-inflation change a tire’s footprint. You’ll want to keep an eye open for both conditions.

Over-inflation can result in a number of issues ranging from a harsher ride to irregular/fast treadwear, and should be avoided. (Irregular wear can be corrected if detected early enough, but can be avoided through proper inflation.)

Under-inflation also can create a number of serious problems that can cost you time and money. Under-inflation causes tires to flex more as they roll down the highway, and generate excessive heat. These things cause tire component integrity to deteriorate if left unchecked. Under-inflation also can lead to separations, irregular/uneven wear and increased potential for road hazard damage. In addition, under-inflation hurts a truck’s fuel economy, due to the simple fact that under-inflated tires force a vehicle’s engine to work harder.

Factors that Affect the Correct Tire Pressure

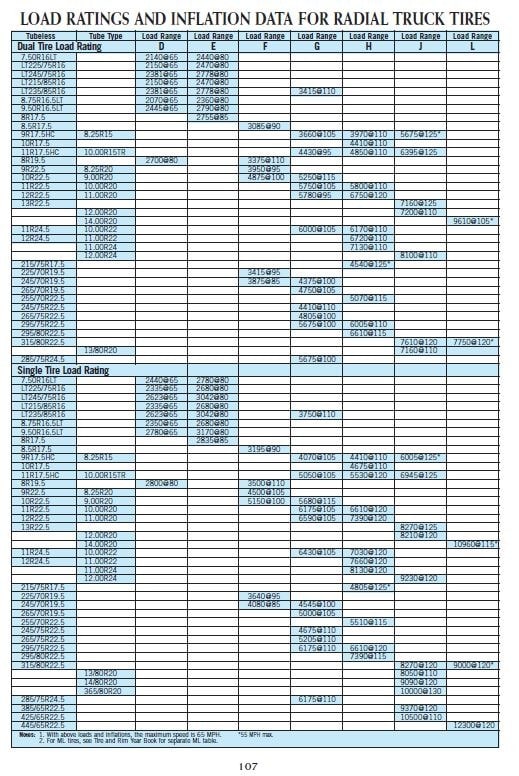

At this point, you might be asking, “What’s normal when it comes to tire pressure?” Tires are engineered to run at specific pressure levels based on the load they’re carrying. To determine the correct inflation level for your tires, gather information about your axle loads, refer to load charts like the kind in Figure 1. (For example: For a size 315/80R22.5 Goodyear G289 WHA tire, Load Range L: single tire = 10,200 lbs. at 130 psi; dual tires = 9.090 lbs. at 130 psi.)

Truck operating speed also plays a role in the setting of optimal tire pressure. The tire industry has guidelines for allowing increased maximum loads if vehicle speeds are reduced. Think of large cranes that need to carry heavy loads but move slowly.

Another thing to keep in mind as summer winds down is that ambient temperature has an effect on inflation levels. Inflation pressure drops approximately 1 to 2 pounds for every 10-degree decrease in ambient temperature. Drivers should also check inflation pressures at least once a week, using a calibrated tire gauge or a gauge that is checked periodically, according to tire industry recommendations. Again, inflation checks take time and manpower, but the benefits are worth the investment.

Maintaining a record of tire inflation—plus tire inflation checks and adjustments——can prove beneficial, as well. Truck tires often represent a significant capital outlay, and like any investment, should yield a profitable return. Frequent air pressure checks and adjustments will help you achieve this.

Using Data to Optimize Your Truck Tire ROI

Truck tires can represent a substantial capital investment. Careful, systematic documentation of tire maintenance and performance can help you optimize your truck tire returns. There’s nothing wrong with tracking tire installations, removals and associated costs using paper and pencil. But as the number of trucks in a fleet increases, keeping records “the old-fashioned way” becomes more complex. Fleets at that point become excellent candidates for an online tire management tool—particularly one that can tap into tons of tire data.

Effective online tire management tools don’t just track tire purchases and installations. They should have the ability to track reasons for tire removals, as well. Knowing why tires were removed, plus of the age of tire casings and the number of retreads these casings are yielding, can indicate if your tires were properly maintained.

Furthermore, knowing the wear rates of the tires in your fleet allows you to anticipate peaks and valleys in the replacement tire purchase cycle, which can help with budget planning. Tire management software also will help you evaluate tire performance on different sets and types of vehicles to help you make better decisions.

In addition, tire performance between different company locations or terminals can be tracked the same way. This helps fleets pinpoint problem areas and establish best practices based on tire performance in one or more locations. Information is power, and to stay ahead of the competition, you must make the data work for you. Tires should be viewed as part of a holistic system—a “total package solution.” Tire quality is just one piece of the puzzle. You also need to capitalize on the information—and information tools—that are at your disposal. Tracking tire data is imperative. By tracking tire data and following prescribed air pressure maintenance practices, you can optimize your truck tire investment.

Brian Buckham is Marketing Manager for Goodyear Commercial Tire Systems. A commercial trucking industry veteran, Brian supervises marketing activities for Goodyear Commercial Tire’s long haul and mixed service segments. [email protected].

Jose Martinez is Business Solutions Manager for Goodyear Commercial Tire Systems. He supervises marketing for the Goodyear-FleetHQ suite of business solutions, as well as Goodyear Commercial Tire Systems’ digital properties.Jose can be reached at[email protected].