A quality fuel additive with combustion catalyst is a proven value that will move your fleet forward and ahead of your competition.

By Alec Taylor

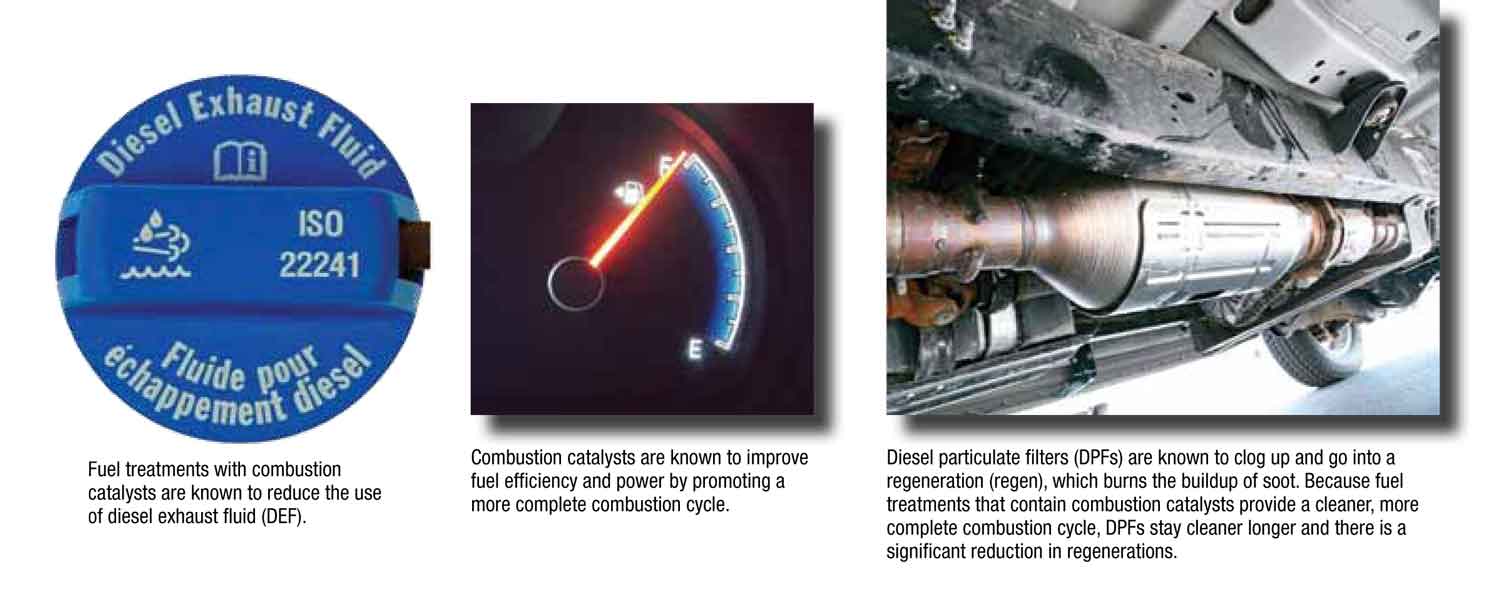

Is 2020 the year that combustion catalysts gain the acceptability and adoration of the heavy trucking/equipment community? What is the difference between fuel additives with and without combustion catalysts anyway? Fuel additives range greatly in strengths and weaknesses. Most of the better ones offer the benefits of added lubricity to make up for that which is lost in the process of removing the sulphur from the fuel, detergents to clean injectors and fuel pumps, chemicals to remove water and stabilizers for fuel that sits for extended periods of time. These are generally considered to be the four core attributes of a good conventional fuel additive. But what about a fuel additive that contains a combustion catalyst? How do they differ from a typical conventional fuel additive? Do these types of fuel additives actually work or is this just another “mechanic in a bottle” scam? In this article we are going to explore combustion catalyst technology and how it is leaving its imprint across a variety of fuel using industries.

What is Catalytic Combustion?

Catalytic combustion is a chemical process which uses a catalyst to speed desired oxidation reactions of a fuel and by doing so reduce the formation of undesired emissions like soot and greenhouse gases, especially pollutant nitrogen oxide gases (NOx). This technology is designed to lower the combustion point in fuel so that fuel will combust at a lower temperature and burn for a longer period of time resulting in a more thorough overall combustion. There are not many combustion catalysts on the market, but the ones that are available usually come in liquid form, although there are a few sold as single use pellets. The incorporation of this technology enhances these additives by providing the user with a more thorough, and therefore more powerful and cleaner, combustion.

Who Can Use Combustion Catalysts?

All industries that use oil derived fuels can benefit from a combustion catalyst. Most combustion catalysts are designed for just diesel fuels, but there are those out there that can be used in both diesel and gasoline powered engines. Companies that run diesel engines that tend to drive in stop-and-go patterns and who idle a lot like sanitation, busing and the construction industries will benefit most from a combustion catalyst. This is because these vehicles produce more soot when they idle and run at slow land speeds—as a result, they do not burn fuel as efficiently. The fact that they do not get the opportunity to get out on the highway and run at high rpms is a further disadvantage. A combustion catalyst will help to ensure a fuller combustion cycle for all vehicles, but these types of industries will certainly benefit the most.

Benefits of Combustion Catalysts

Power and Fuel Economy

Combustion catalysts work by accelerating the burn of diesel so that more British Thermal Units (BTUs) of heat are released earlier during the cycle instead of going uncombusted and instead being wasted as soot and other emissions. The catalyst aids in creating a more thorough burn of the fuel, so that the user is getting the most out of the fuel as possible. The less wasted fuel, the farther a tank full of fuel will go. Tests of many of these additives containing combustion catalysts have shown fuel savings in the 4 to 12 percent range across a wide range of vehicles. Using combustion catalyst technology also results in an increase of the power and responsiveness of the vehicle. Drivers often report more powerful starts with less soot in the morning, especially in colder weather, when using a combustion catalyst.

Emissions, Regens, and DPFs

Due to the more complete combustion, there is a significant reduction of unburnt fuel, or soot/smoke as well as other gases being diffused into the atmosphere or emissions cleaning systems. Intertek has recently completed testing of one of the most well-known additives in this class, Fuel Ox with Combustion Catalyst. Intertek’s analysis of Fuel Ox with Combustion Catalyst showed a reduction of NO, NOx, and CO2 by 8, 12 and 20 percent respectively. Not only is this reduction in greenhouse gases favorable to our environment, but the more thorough combustion is also especially effective on vehicles with the Diesel Particulate Filters (DPF) systems. The resulting reduction of soot being caught in the DPF’s leads directly to a considerable reduction of regenerations. In fact, many users report 50+ percent less regens. This not only means less maintenance costs, but also less wasted man hours and more vehicle production hours as well. Furthermore, this reduction of soot also reduces the number of times a DPF needs to be cleaned or “baked out”, thereby reducing maintenance costs and extending its life by as much as 2x. In one case, a customer reported that they were bringing their five trucks into the repair shop to get their DPF systems manually cleaned out every few weeks on a regular basis. The repair shop was charging them to take apart the exhaust systems to clean them and reassemble them back together. The exhaust systems would work fine for a couple weeks or so until they were forced to go back to the repair shop to get the same temporary fix. Once this company started using the Fuel Ox with Combustion Catalyst this process was extended to three months or more. Most users whose trucks and equipment regen often will experience these types of results while also seeing a large decrease in soot buildup on their EGR coolers.

To back track for just a moment, let’s talk about greenhouse gases and their relationship with Diesel Exhaust Fluid (DEF). While DEF was at one time a small inconvenience and cost, it is clearly growing—or has grown—into a major issue for all of us. DEF is used for one single reason—to be added to the exhaust as it passes through the Selective Catalytic Reduction (SCR) chamber during which it combines with the greenhouse gas, NOx, creating harmless water that drips out the bottom. Some combustion catalysts, by reducing the temperatures of the combustion, will create less NOx, which in turn results in less DEF fluid being used. Many users of Fuel Ox with Combustion Catalyst report using 20 to 50 percent less DEF depending upon the vehicle.

Cleaners and Longer Engine Life

Another important benefit of combustion catalysts is longer engine life. A more complete combustion means less emissions which has its own set of benefits. One of these is that soot is extremely abrasive and corrosive to engine parts. Excess soot causes increased wear to your rings, fuel liners, camshafts, bearings and other engine parts. Anything that helps to eliminate soot also helps to extend the lifespan of your engine.

Improving Overall Efficiency

At the end of the day, all we really want to do is to improve the overall efficiency and save money on our equipment and vehicles. After all, they are expensive investments that we want to preserve as long as possible. One of the best ways to do this is by making sure that you put the highest quality fuel into it which we all know seems harder and harder to do each day. Any fuel additive that has the basic four core benefits of added lubricity, detergents, water removers and stabilizers is going to help the fuel quality, but using one of today’s combustion catalysts can definitely take your fuel to the next level. Enjoy greater power, smoother engine operation, less DEF consumption, increased fuel efficiency and fewer regens when using a combustion catalyst. The cost of a good fuel additive with a combustion catalyst versus a conventional additive is slightly more and most will cost you between 3 and 7 cents per gallon to treat your fuel. This equates to about 1 to 2 percent of the cost of the fuel you are currently using. When you consider the improvement that comes with it—5 to 10+ percent better mpg, 50+ percent less regens and 20 percent less DEF usage—it is easy to see why so many are turning to a fuel additive with combustion catalyst. A quality fuel additive with combustion catalyst is a proven value that will move your fleet forward and ahead of your competition. | WA

Alec Taylor has been the Director of Operations of Fuel Ox (Asbury, NJ) since 2014. He oversees production, sales and the overall direction and organization of the company. Alec works side-by-side with his partner and father, Rand Taylor. Alec and Rand are dedicated to alleviating fuel related issues for their current and future customers. He can be reached at (844) 8-FUELOX or e-mail [email protected].