The history of a family who has been building garbage trucks for more than 65 years.

Zachary Geroux

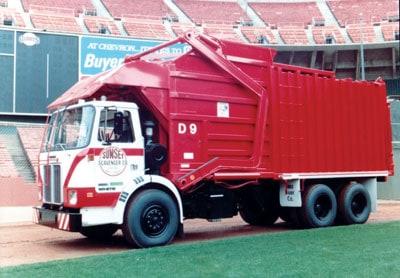

I have a confession. I fell in love with garbage trucks and the waste industry at a very young age. The front loader that serviced my apartment complex twice a week holds a special place in my heart, and I still remember the name of my garbage man, George Minter, who let me pull the cable levers to lift and level the containers. For a young boy, there was nothing cooler in the entire world.

The family who built this truck is the object of this month’s article, and, in my mind, a big part of why front loaders are my favorite type of collection truck and why I love this industry so much. To them and George I dedicate this month’s article, for they will never know how much of an impact they have had on my life.

Bemars Inc.

To start telling this story, we have to start at a time when the commercial refuse equipment we know of today was non-existent. Ed Kouri served as a SeeBee in the Army during World War II and after the war ended, came to California and started working for Vincen Bowles. In 1947, the S. Vincen Bowles Company in Los Angeles, CA started building heavy equipment for use in construction. It was not until 1952 when Vince built the first front loader and changed the refuse industry forever. Ed Kouri was a welder and shop foreman for Vince by this time and helped construct many of the earliest front loaders and roll-off trucks in the Western U.S.

Seeing the vast market Los Angeles and the West Coast held, Ed decided in 1960 to break off from Bowles. He teamed up with fellow Bowles employee, Dewayne Bolme and Ken Carlson, a former sales manager from Cook Brothers, to form Bemars Inc. in Montebello, CA. They came up with the unusual name “Bemars” by combining the first names of their wives, Beverly, Margaret and Mary.

Quickly growing because of their quality workmanship, Bemars became one of the top three refuse equipment manufactures in the Western 12 states by the mid 1960s. They offered a Full, Partial and Top Pack version Front Loaders as well as Roll Off and Container Delivery trucks. The firm remained popular and prosperous for 12 years until they decided to dissolve the partnership and sell the entire company to Maxon Industries in 1972. Maxon, who had purchased Western Body and Hoist two years prior, became the largest refuse equipment manufacturer in Los Angeles overnight, rivaled only by Bowles. Brand new to the refuse industry, Maxon continued the Western and Bemars equipment lines as a subsidiary until the late 1970s when they dropped both names and restructured everything under Maxon only.

After the partnership dissolved, it is unclear where Ken Carlson went and my research has not supplied any further history. Dewayne Bolme went to go run the sales department for Chet Ott at C&O Manufacturing in Santa Fe, CA bringing many of his Bemars customers to this new company. After C&O sold to Dempster in 1983, Dewayne finally retired to continue refining his golf game.

Able Body Company

Still under a non-compete from Maxon, Ed Kouri moved up to the San Francisco area and started Able Body Company in 1974 under his son and apprentice Matt’s name. As Able Body, Ed continued the same line of equipment he had at Bemars, continuing to refine and perfect it throughout the 1970s. He started to make drop frame side loaders to compete with the popular Shu-Pak and began building dedicated recycling truck to accommodate the popular recycling movement of the early 1980s.

With many ties still to Southern California and selling quite a few trucks in that market, Ed started Able Body Sales and Service in Pico Rivera. Calling upon Rich Mellum, former Bemars General Manager to run the operation, the initial concept was to have Rich sell and repair bodies sold in Southern California until he started building his own front and side load trucks. At this point he became a separate entity, which caused some confusion for the customer, and Able Body Company literature often had to state the distinction in their advertisement.

The Kouri family continued to see success during the 1980s, selling their bodies in every state west of the Rockies. Ed’s health started to decline during this period and his son’s Matt and Tony started running more of the day-to-day operation. The automated side load technology was still young and hadn’t caught its true fire yet with many markets still running manual residential collection. Tony saw the potential in this emerging market and in 1989 took a welder to the back of the shop and spent a few days creating an automated arm concept to test and field. A test arm was retrofitted onto a modified drop frame side loader and Oakland Scavenger agreed to route test the new arm. Tony recalls walking behind the truck collecting more trash spilled on the ground than what made it in the truck. However, before he could continue to perfect his design, the high operating costs of California and Union pressure forced them to close operations.

Bridgeport and a New Beginning

In 1990, Tony decided to move the operation out to Texas and opened up shop in Bridgeport with the few pieces of metal fabrication equipment he brought with him. Operating as Bridgeport Refuse Trucks, Tony built his first front loader for Portland Disposal Company in Portland, Oregon. This truck had smooth sides and lacked the 2×2 ribs common on their previous front loaders because they didn’t bring the machine to form the rib. However, this worked out for the best because the industry was moving away from ribbed bodies and toward smooth sided trucks. Matt decided to remain in California, run their western sales division and maintain relations with their West Coast customer base.

Ed moved out to Texas with Tony and his daughter Philomena, who had joined the company as the office manager. Even with failing eyesight and declining health, Ed made sure he lived close to the production floor where you would often find him involved in the construction and design of the trucks. Tony continued to refine his automated arm design and with Ed’s help, saw growth in their new market.

Ed passed away in 1997 surrounded by family and friends. From the very beginning, he had helped shape the face of the commercial waste industry and some of his design innovations are still used on trucks made today. The Kouri family has been building garbage trucks for more than 65 years and holds the record for being the longest family owned builder in the U.S. You can find their trucks coast to coast, which is a testament to the vision Ed had in California more than 50 years ago. | WA

Zachary Geroux is a historian, photographer and owner of Refuse Truck Photography. He lives in Western Washington with his wife where he currently works full time for the Air Force and has been driving garbage trucks off and on for the past nine years. He can be reached at [email protected] or visit www.refusetruckphotography.com.

Visit Refuse Truck Photography under the Waste Advantage section to see more pictures and video of Bemars, Able Body and Bridgeport trucks. Also, be sure to stop by the Refuse Truck Photography Facebook page to join the conversation on this month’s article

If you would like to have your company’s history featured in a future Vintage Waste Corner, contact Zachary via the contact information above to set up an interview time. These articles are purely meant for educational purposes to document and preserve the history of trucks and the companies.