The history of a small repair shop that came to dominate the Southern California Market.

Zachary Geroux

Brothers Jose and Eduardo Ghibaudo immigrated to Los Angeles from Argentina in 1967 and shortly after began working for Bemars Inc. building refuse bodies. When Bemars sold to Maxon Industries in 1972, all of the employees and equipment were absorbed into the company. With the purchase of Western Body and Hoist two years prior, Maxon had acquired two of the largest refuse body building companies in the Southern California market and for several years after, continued the bodyline of each respective company by just adding “Maxon” to title.

The 1970s saw the explosion of small “micro-builders” within the So Cal market with ex-Bemars and Western employees striking out on their own, building bodies for the numerous haulers operating in that area. Often these bodies were copies of the one’s they made for their former company. Many times because they were working out of a rented yard and didn’t have the big metal forming tools, they subbed out the majority of their welding to fabrication shops or repaired bodies. Jose and Eduardo left Bemars just prior to Maxon’s purchase. Initially, they would repair trucks at customers’ facilities as they did not have a facility of their own, sometimes at night with only their own car headlights lighting their work area. The eventual company name was derived during this time and began as American Repair. At the urging of several customers, they decided to begin producing new bodies. It was decided then in an effort to not be known only as a repair company, they blended the words American Repair and the name Amrep was born.

Early Amrep

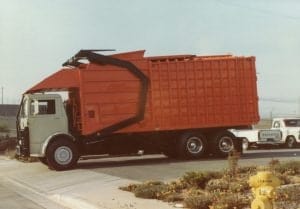

In 1976, they opened up Amrep Inc in Huntington Park, CA and started building front loaders, roll-offs and even a front load roll-off body, popular with many of the smaller companies who only did commercial—giving them the benefit of using one truck for two applications. While their front loader looked like an almost exact copy of the legacy Bemars half-pack, appearances can be deceiving. The 1976 Amrep front loader introduced a feature that would later become an industry wide standard—the scissor-style packing rams. Amrep began to build up a name for themselves within the market, having to compete with the already popular and established giants Bowles and Maxon, as well as competition from East Coast companies who had started to make inroads into California.

By the turn of the decade America was still recovering from the economic recession caused by the Vietnam War and technology had began to quickly develop so as to allow the average homeowner the possibility of owning computers and other electronics. A culture had developed where futuristic and flashy-looking devices quickly sold, retro technology was out and people had accepted that disco was dead. The brothers knew they needed a new and radical looking body design to stay in the game and one step ahead of the competition. In 1984 they filed their first patent for an ultra-lightweight, octagonal shaped front loader which featured a half-blade packer and follower manipulated by their scissor-style packing rams. Along with a drip pan positioned underneath the tailgate seals, the Octagonal front loader quickly became a favorite of haulers and today you will be hard pressed not to find a company operating in Los Angeles or

San Diego who hasn’t owned or still owns one of these bodies.

With the filing of this patent, Amrep also began to diversify their refuse line by offering a manual side loader for fleets in need of a residential truck. While most companies use front loaders for commercial and industrial accounts, many in the Southern California area used them for residential routes as well. The technology of automated residential collection was still young and very few body manufactures were offering automated side loaders due to complications with arm design. Manual collection was still king and with the economic hardship still being felt from the 1970s, the ability of using one truck for two purposes appealed to many haulers. While this was not a new concept, being used since the birth of the front loader, the City of Los Angeles decided this was the future and in 1984, placed a huge order for 125 Amrep front loaders with follow on orders pending with plans for an entire fleet conversion. Western Waste, a fast growing waste hauler with humble beginnings in Los Angeles, also used this method. They were a big Amrep customer and with their growth and acquisition of companies as far East as Louisiana, brought this style of collection to the south. Amrep’s new lightweight front loader seemed perfect for this pairing by giving the driver a high ton capacity and a shaped body that allowed the driver greater visibility behind his truck, which was a huge safety factor across the board especially in a fast paced residential neighborhood. By 1986 production demands would lead Amrep to move to its current location in Ontario, CA.

Breaking into the World of Automation

Automated technology continued to be developed and refined throughout the 1980s and finally started to infiltrate the market in a big way toward the end of the decade. Maxon Industries had mated the independently built Sunbelt Automated Systems arm to their Legal One copy of Amrep’s Octagonal body around 1991 and the same year Amrep had unveiled their automated side loader design with a demo unit to the City of Los Angeles, which was eventually sold to BFI in Phoenix, AZ. A variation of their octagonal body, its arm was similar enough in operation and design that Sunbelt sued for patent infringement and was later awarded $1.6 million plus future royalties and attorney fees, causing Amrep to file for bankruptcy protection. In 1996 by making only a minor design change, Amrep filed and was awarded its own patent on its automated arm and they were free to manufacture and sell the modified arm. While finding their half-blade with follower design extremely efficient for automated collection, their early trucks had some initial design deficiencies which were later corrected.

In 1993, Eduardo decided to leave the company and start Edge Manufacturing in Corona, CA where he was president until his passing in 1998. Eduardo offered the Octagonal front and manual side loader as well as a roll-off frame and bin carrier. His son Dennis now runs the company where it continues to grow and expand on his father and uncle’s experience and trade of building quality trucks.

Even though the automated truck went through its initial growing pains due to some design issues, it soon became the go-to truck for companies looking to convert their fleet from manual collection. Amrep even offered to modify their front loaders with their new automated arm in order to cut down the costs for haulers. The City of Los Angeles, among others, placed orders for hundreds of trucks giving Amrep the staple and future it needed in the refuse industry. They also started up a cylinder and machine shop, fabricating and repairing hydraulic cylinders. Not only do they create cylinders for their trucks, but also replacement ones for other manufacturers’ bodies.

Continuing the History of Innovation

Amrep is the only “micro-builder” who has survived from the 1970s and today has outgrown the roots from which it came. Becoming the largest builder of refuse trucks on the west coast, they have enjoyed a success that is unrivaled by any So Cal builder since Bowles built his first front loader in 1952. Along with the industry standard changes they initiated, they were also the first company to use Hardox Steel in the construction their bodies, making them stronger and lighter, as well as a CNG in frame roll-off hoist designed to meet standards in an ever increasing environmentally friendly world.

In the late 1990s Jose began transitioning the leadership and ownership of Amrep, Inc. to his two children Gabriel Ghibaudo and Vivian Ford and longtime employee and friend Eric Mattson insuring Amrep’s survival beyond his own life. Jose Ghibaudo passed away on March 9, 2012 surrounded by his family and loved ones. His son Gabriel “Alex” succeeds him as president of Amrep and even though the refuse industry lost one of its last visionaries from yesteryear, the legacy of the Ghibaudo brothers lives on through every Amrep and Edge truck on the road today and is a testament to the craftsmanship that was passed on to them by the forefathers of the refuse industry.

Zachary Geroux is a historian, photographer and owner of Refuse Truck Photography. He lives in Western Washington with his wife where he currently works full time for the Air Force and has been driving garbage trucks off and on for the past nine years. He can be reached at [email protected] or visit www.refusetruckphotography.com.

Visit Refuse Truck Photography under the Waste Advantage section to see more pictures and video of Amrep trucks and be sure to stop by the Refuse Truck Photography Facebook page to join the conversation on this month’s article