Wasted food is typically an excellent source of energy in an anaerobic digester. However, depending on its source, food waste can be highly contaminated with a variety of other materials. This contamination interferes not only with the good contact needed between bacteria and organic material, but can cause significant operational issues for digester components.

Christine McKiernan

Wasted food is a huge topic of discussion lately—and that’s a good thing. More than 36 million tons of food waste per year are disposed of in landfills in the U.S. alone. Although volumes could be written on the societal issues connected to why so much food is wasted in the first place, this article will instead focus on how to put food that is wasted to good use by diverting it for energy generation, as well as sources and effects of contamination.

Anaerobic Digestion and Contamination

Several states and major metro areas recently implemented bans on food waste going to landfills and, instead, indicated sending the discarded food to composting or anaerobic digestion operations. Wasted food is typically an excellent source of energy in an anaerobic digester. Anaerobic digestion relies on ancient bacteria from the Methanogenic Archaea domain of microbes which function in oxygen-free digesters. In this oxygen-free environment, bacteria can convert organic material into methane—or renewable energy. In order for these bacteria to convert food waste to energy, they must make good contact with the food for a sufficient period of time. However, depending on its source, food waste can be highly contaminated with a variety of other materials. This contamination interferes not only with the good contact needed between bacteria and organic material, but can cause significant operational issues for digester components.

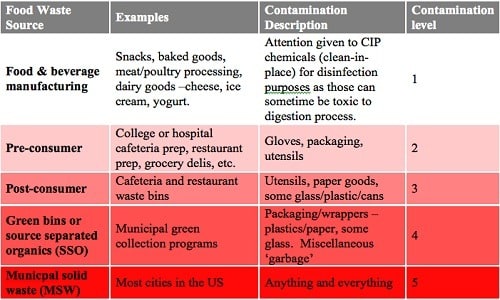

Let’s consider a number of different sources for wasted food. Each food waste stream has its own set of obstacles, some more challenging than others. Referring to Table 1, different sources of food waste have been generally characterized by their level of contamination using a scale from 1 to 5, with 5 containing the most contamination.

The contamination level becomes much more significant once food has gone through the hands of the consumer, and simple screening will often not suffice. Many institutions or commercial facilities implement educational programs encouraging consumers to dispose of food in specially marked bins—programs such as these can have a tremendous impact on contamination reduction. Optimizing the energy potential of various wastes and their contaminants requires careful review and selection of appropriate digester technology.

Wet Vs. Dry Digester Technology

Digestion methodology is divided into two major categories: wet or dry fermentation. Wet digesters come in various configurations, such as complete-mix stirred, plug flow, mixed plug-flow and variations of these. The primary distinguishing factor between the configurations is the percent solids, or %TS, that the digester operates at. Wet digesters typically handle input waste that is pumpable and operates anywhere from 7 to 15%TS. Even on the higher-solids end of the “wet digestion” spectrum with a 15%TS, the material is still fairly wet. (Note: discussion of wet digestion in this article does not include high rate digesters, which operate at 1 to 2%TS).

Wastes with little contamination or requiring only simple pre-screening often make their way into wet digesters. One such scenario could involve screened and pulped waste collected from a university kitchen or a grocery store’s prepared foods kitchen. If available, these wastes could be combined with material from a nearby potato chip manufacturer. These combined wastes can easily be pumped into a wet digester and have the potential to produce significant volumes of methane for energy use.

Dry digesters, on the other hand, are typically batch operated tunnels or bays which operate with input material TS of 20% and higher. Feedstock or wastes loaded into a dry digester are typically stackable and cannot be pumped. Dry digesters are extremely useful in applications where liquid wastes are not available for creating pumpable slurries as is done in wet digestion.

Expired foods or reject produce from large grocers would be scenarios where dry digestion may be the best option; here, the waste itself can be made up of large items—i.e watermelons, heads of lettuce, ends of deli meats, etc. This type of stream lends itself to use in a dry digester where it is not necessary to pulp the material.

Municipal collection of green bins or municipal solid waste garbage bins typically result in the most contaminated streams. This waste material often contains a variety of contamination and requires the highest level of sorting and screening to produce a stream suitable for digester use; however, not all the contamination is removed.

Consider a typical collected garbage bag. Its contents may include glass bottles, plastic yogurt cups, batteries, assorted packaging, shoes, even electronics; glass might break, plastics may crack … and so on. Many of these inorganic materials will pose little problem as most modern waste receiving stations can remove metals with magnets, float out plastics, sort out large items and screen small items down to 2” in diameter. The resulting 2” organic fraction—although still containing some glass or plastic, etc.—becomes quite suitable for use in a dry digester, since maceration and pumping are not required for the system. If wet digestion is to be used with 2” fraction, then additional screening is required to protect equipment from the effects of excess ground glass, etc.

Understanding the Economics

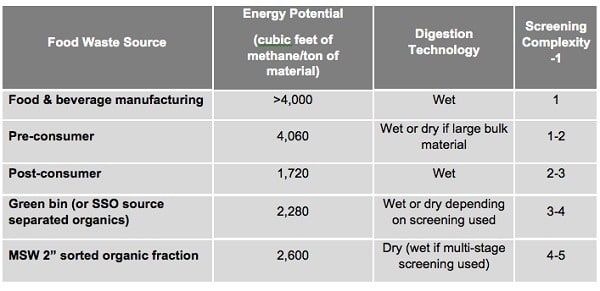

Contamination levels not only can influence digester technology choices, but project economics as well. In Table 2, the various food waste sources are noted by their potential available energy. Potential energy is measured by a series of lab scale digestion tests called biochemical methane potential, or BMP; using data such as this is useful for project planning to begin understanding the potential economic benefits and which technology would be the best fit.

For example, if a project is to be developed using 5,000 tons per year of post-consumer waste plus another 10,000 tons per year of green bin waste, the expected energy output would be in the range of 600-650 kW or 45,000 to 50,000 MMBTU/yr, (not including any thermal recovery from use of CHP genset). Depending on the market for this energy, the project may earn in excess of $500,000/yr in electric energy sales. However, these earnings must be weighed against the necessary infrastructure required to receive and prepare the food waste. In a subsequent article we will address the residuals resulting from the various waste streams and digestion technologies. Different waste streams and contamination levels have varied impacts on the possible end uses and/or processing of the residuals as they are converted into useful by-products.

Christine McKiernan is the Vice President of Development and Technology of BIOFerm™ Energy Systems (Madison, WI). She has been engaged in the water and wastewater arena for 28 years actively designing, constructing, operating and troubleshooting projects in anaerobic and aerobic treatment. Through her participation in various projects and as Director of Engineering for Microgy, she oversaw the process design and technology evaluation, process troubleshooting and project engineering. She has reviewed and designed anaerobic treatment facilities for the capture of methane from biogenic waste materials such as food processing waste, agricultural crops and animal slaughter. Christine can be reached at (608) 467-5523.

*This document cannot be reproduced without prior consent from BIOFerm Energy Systems. Contact Whitney Beadle at [email protected] for article use.

Table 1

Food Waste Source Sorted by Contamination Level

Table 2

Food Waste Source Sorted by Energy Potential. 1 – Scale of 1 to 5, 1 being less complex and 5 being most complex.

Tables courtesy of BIOFerm.