The MBT concept is an applicable solution for the U.S., especially for its efficient diversion of food waste from landfills. It is a solution for diverting organics from the mixed MSW and for efficiently recovering the material and energy without source separation. In planning one, understand markets and values first so net economics can be better predicted.

Ljupka Arsova

The latest numbers on municipal solid waste (MSW) disposition in the U.S., as published by the United States Environmental Protection Agency (– USEPA) in 2014, show 26 percent of the generated MSW is recycled, eight percent is composted, 12 percent is combusted with energy recovery and 54 percent is landfilled. A Biocycle/Columbia University State of Garbage Survey show 69 percent of the MSW is being landfilled. The biggest environmental impact of the fractions of the MSW going to landfills has the food waste. According to the — USEPA food waste comprises up to 21 percent of the MSW currently landfilled in the U.S (see Figure 1).

When food waste (organics) is landfilled, it generates methane, contributes to leachate generation and has the biggest negative environmental footprint of all MSW fractions. The environmental impact of the landfilled organics was address by the European Union (EU) in 1999, when standards were set for landfilling organics, which led to development of technical solutions for dealing with organics. This directive defined that biodegradable waste must be reduced to 75 percent of 1995 levels by 2006, to 50 percent of 1995 levels by 2009 and to 35 percent of 1995 levels by 2016.

One of the widely implemented solutions in the European Union is Mechanical Biological Treatment (MBT) concept. With the steady trend of higher diversion goals and recycling rates being set for organic waste in the U.S., the MBT concept may be an option for us here, too.

History of MBT Plants in the EU

The main event that initiated the development of the MBT concept was the EU Landfill Directive set in 1999. High landfilling taxes (up to $130/ton of MSW) were additional drivers for lowering the amount of waste being landfilled and instead being processed at MBT plants. The growing demand for high-grade refuse derived fuel (RDF) around Europe additionally motivated the development of the MBT plants as one major by-product of these plants is RDF (~40 percent by weight).

The MBT concept was seen as an alternative to incineration for decreasing the amount of organic and other MSW being landfilled, and for recovery of recyclables, and generation of biogas and compost.

Status of the MBT in European Union

Though the MBT concept originated in Germany in 1999, it has since been successfully spread around Europe. The leading MBT markets in Europe are Germany, Austria, Italy and Spain.1 The most recent numbers on existing MBT plants are from 2011 as follows:

- Germany has around 46 operating MBT plants with approximately 6.6 million tons/year of processing capacity. The MBT plants process around 25 percent of the MSW generated in Germany, and 20-30 plants (capacity of 2 to 3 million TPY) produce Refuse Derived Fuel.1

- Italy also has a long tradition of using MBT plants. Italy has the most MBT plants, with 133 in operation, and the biggest processing capacity installed, around 15 million tons/year.1

- Austria has 16 operating MBT plants with total authorized capacity of round 800,000 tons/year with exclusively aerobic biological treatment and production of RDF.2

- Spain has 84 MBT plants with operating capacity of more than 10.5 million TPY. Compared to the other countries, Spain has most of the MBT plants with anaerobic digestion as biological process.3

The number of MBT plants has increased 60 percent from 2005 to 2011. The numbers from a 2011 survey shows around 330 MBT plants operating around Europe with processing capacity of around 44 million TPY.4 The number of MBT plants is expected to continue to grow to an estimated 450 plants with around 50 million tons of MSW of processing capacity by 2016.2

MBT Concept

Initially the MBT plants were developed to stabilize the organic fraction of the MSW prior to landfilling, but they evolved to become complex facilities that process MSW to separate recyclables, treat the organic fraction to produce biogas and/or compost, and produce refuse derived fuel (RDF). The MBT plants accept for processing the mixed MSW as collected after source separation of recyclables and organics has been completed. The main goals achieved by the MBT are as follows:

- Decrease the amount of MSW destined for landfilling and thermal treatment

- Reduce the amount of biodegradable material going to landfills

- Reduce landfill gas production (greenhouse gas)

- Reduce landfill leachate contamination

- Recover recyclables including soil amendment product

- Produce solid fuel with high energy content (RDF)

The two core elements of the MBT plants are the mechanical processing of the incoming waste and the biological treatment of the residue and the segregated organic fraction.

The role of the mechanical processing is to separate the fine fraction for biological treatment (high organics and moisture content, low calorific value), and the coarse fraction (low moisture content, high calorific value, recyclables). The mechanical treatment includes shredders, size and shapes screening, separators for ferrous and non-ferrous materials, optical sorters, palletizers, etc.

The organics as separated in the mechanical processing are subject to biological processing. The biological treatment can be different and the most common implemented options are:

- Aerobic bio-drying/ bio stabilizations

- Aerobic In-Vessel composting

- Anaerobic digestion (AD)

Types of Modern MBT

The design and the type of implemented mechanical and biological treatment at the MBT plants depend on the anticipated final results of the MBT plant. Based on the anticipated results the modern MBT plants are divided into two major groups:

- MBT with a major landfill fraction

- MBT for RDF production

The MBT plants with major landfilling fraction have a landfill diversion rate of around 60 percent, and the MBT plants dedicated to RDF production reduce the amount of waste being landfilled to 90 percent. The MBT plants with a major landfill fraction have aerobic composting or anaerobic digestion (dry or wet) as biological treatment. The final product of these plants has high concentration of organics and in some countries is used as dirty compost.

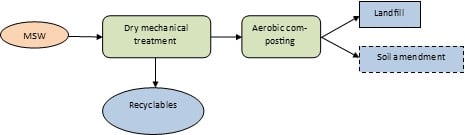

The MBT plants with aerobic composting as biological treatment are the simplest and the most reliable MBT process, require the lowest capital cost and make sense on a small scale as well. These MBT plants achieve less than 50 percent waste reduction. The only disadvantage of these plants is they do not recover energy as biogas is not produced. The simplified process diagram of the aerobic MBT plant is shown in Figure 2.

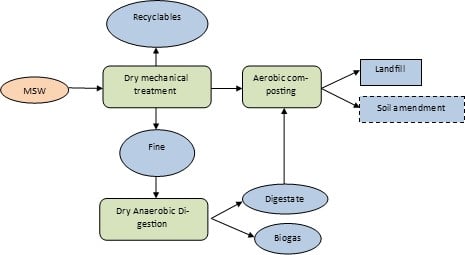

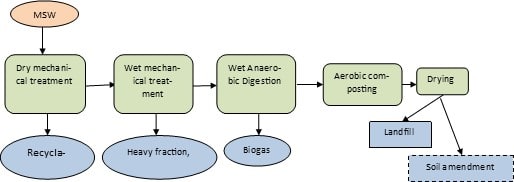

The MBT plants with anaerobic digestion are complex plants that have higher capital costs, require highly skilled personnel and its AD technology is more sensitive than aerobic composting. However these plants recover energy as biogas in addition to recovering materials. The anaerobic MBT plants can use both “dry” and “wet” AD technologies, and the simplified process diagrams of the anaerobic MBT plants are shown in Figure 3 and Figure 4.

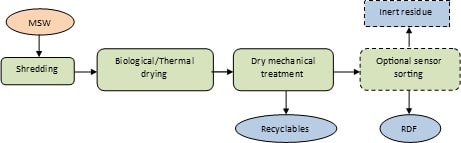

The MBT plants for RDF production have physical or biological drying and no biological processing such as composting or anaerobic digestion. These plants, also known as Mechanical Biological Stabilization (MBS) or Mechanical Physical Stabilization (MPS) plants, are very reliable and achieve 65-90 percent of landfill diversion through high material recovery and significant RDF production. Simplified process diagrams of the MBS/MPS plants are given in Figure 5.

Economics of the MBT Plants

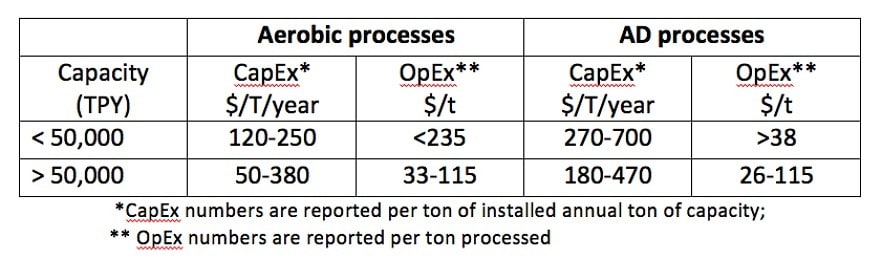

Capital costs for MBT facilities are relatively high. Recent example estimates and actual costs for the construction of MBT plants in the UK fall in the range of $150 per annual ton of capacity of MBT plant with aerobic composting to on average $250 per annual ton of capacity at MBT plant with AD as biological treatment. Operational costs at the German MBT plants have been reported in the range of $45 to $103 per ton of MSW processed.5 Typical costs of the MBT plants around the European Union are shown in Table 1.

In addition to the relatively high capital and operating costs additional financial burden is marketing the final products, the dirty compost and the RDF. Some of the MBT plants are paying tipping fee for the RDF at the power plants and in many cases the final residue cannot be used as fertilizer due to the high concentration of impurities and has to be landfilled for additional fee.

Advantages and Disadvantages

The main advantage of the MBT concept is the high flexibility to the changing requirements of the waste markets. The MBT plants can be optimized to meet the specific requirements of the market through increased recovery of recyclables, RDF and biogas production. MBT plants are a holistic solution for material (recyclables) and fuel/energy recovery (biogas, RDF). By reducing the biodegradable fraction in the MSW destined for landfilling, the MBT concept helps minimize the greenhouse gas (GHG) emissions from landfilling untreated MSW. Ultimately, the MBT concept minimizes the overall amount of waste being landfilled, and can contribute to a “Zero Waste to Landfill” objective.

Although the MBT concept has significant advantages it has its own disadvantages as well. One of the issues these plants are facing is the quality of the recovered recyclables and the produced compost. In Germany the compost product is not allowed for agricultural application while in Spain although the quality of the compost is acceptable the local farmers do not want to use it. The MBT plants have high capital and operating costs and therefore make economic sense in areas where they are competitive to high landfilling cost. As waste processing facilities, these plants are also challenged by public acceptance due to odor issues.

MBT Potential in the U.S.

The MBT concept can be compared to the existing concept of the Mixed Waste processing Facilities (MWPF), also known as “dirty” Material Recovery Facilities (MRFs), in the U.S. The level of technical sophistication of the MBT plants is far above the MWPF plants as we know them in the U.S. The MBT concept can be beneficial option for U.S. locations with low recycling rates, zero waste to landfill targets and landfill bans on organic waste. The MBT plants could also be a feedstock preparation solution for the advanced thermal processing technologies.

The MBT concept is an applicable solution for the U.S., especially for its efficient diversion of food waste from landfills. It is a solution for diverting organics from the mixed MSW and for efficiently recovering the material and energy without source separation. In planning one, understand markets and values first so net economics can be better predicted. These are expensive complexes.

Ljupka Arsova is Consultant II at Gershman, Brickner & Bratton, Inc. (Fairfax, VA). She has more than seven years of experience with solid waste conversion technologies, including a combination of national and international expertise in identifying appropriate conversion technologies for existing solid waste management systems. Ljupka has worked with private- and public-sector clients, helping them develop the best technical approach and execute procurement processes suitable for their needs and financial capabilities. She is responsible for maintaining an extensive database of solid waste processing technologies in the U.S. and around the world for GBB. She can be reached at (703) 663-2433 or via e-mail at [email protected].

To learn more about the MBT technologies consider attending the specialized MBT conference ”Waste-to- Resources 2015”, more information on the following link, www.waste-to-resources.eu/International-Symposium-2015.html

Notes

- MBT in Germany and Europe – Development, Status and Outlook- Michael Nelles, Gert Morscheck, Jennifer Grünes- University Rostock- International 9th ASA Recycling Days 2012

- Municipal Waste Management in Austria, European Environmental Agency, February 2013 (2011 numbers)

- Study of the current status of the MBT plants in Spain- Antonio Gallardo Izquierdo at al., Universidad Jaume I de Castelló, CONAMA 2014

- Ecoprog GmbH- The European market for Mechanical Biological Treatment Plants, December 2011

- In-Depth Workshop: Mechanical biological treatment (MBT) as a non-thermal treatment option for mixed and residual waste – Dr. Matthias Kuehle-Weidemeier Renewable Energy from Waste Conference (2014)

- Waste Technology Data Centre (2007).