With the resurgence of interest in waste conversion technologies, the future looks bright for energy and chemical creation from waste resources for which we currently have no markets.

By Gene Jones

With the decline in recycling markets as a result to China, Vietnam and Malaysia shutting their doors to accepting recyclables from the U.S., we now have an oversupply of mixed paper, mixed 3-7 and mixed rigid plastics. The outlook for the recovery of the recycling markets for these materials does not look good in the foreseeable future.

To help solve these diminishing markets, waste conversion technologies are being looked at with great interest and may soon come to the rescue with solving the problem.

What Are Waste Conversion Technologies?

Technologies that convert municipal and other waste streams into fuels and chemical commodities—termed conversion technologies—are rapidly gaining interest here in the U.S. again.

In 2008, waste-to-fuels technologies were looked at when energy prices were high. This time around the interest is being generated due to a lack of markets for our recovered materials. Here are three leading technologies that are coming to the forefront.

Pyrolysis

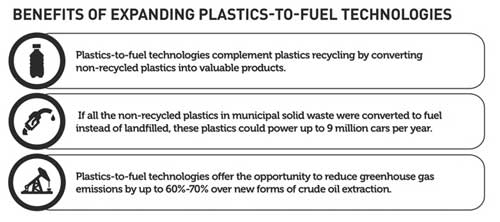

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an inert atmosphere (without oxygen). The conversion of plastics to fuels is leading the way with pyrolysis. The American Chemistry Council’s Plastics-to-Fuel & Petrochemistry Alliance was formed to help foster the conversion of plastics to fuels and chemicals.

According to ACC, companies are transforming used, non-recycled plastics into fuel and petroleum-based products. These plastics-to-fuel technologies, which complement ongoing recycling efforts, are being embraced as a way to recover clean energy from plastics that cannot be economically recycled. Growing interest and investments in plastics-to-fuel technologies can reduce the amount of waste sent to landfills and generate fuel and other useful products to help power America’s transportation system and local economies.

Photo courtesy of Brownstoner (www.brownstoner.com/services/lighting-nyc/d58fa2fb56ea60/slope-gas-lamp-repair-brooklyn-ny-11215/).

Gasification

Gasification is a process that converts organic—or fossil fuel-based carbonaceous materials—into carbon monoxide, hydrogen and carbon dioxide. This is achieved by reacting the material at high temperatures (>700 °C), without combustion, with a controlled amount of oxygen and/or steam. The resulting gas mixture is called syngas (from synthesis gas) or producer gas and is itself a fuel.

Gasification is nothing new. It has been around for a long time. Ever hear of a Gas Light or Gas Lamp District? Back in the late 1800s and early 1900s most metropolitan areas were powered by the gasification of coal to produce fuel for the street lights. This technology has come a long way since then and offers tremendous opportunities with regard to municipal solid waste.

Anaerobic Digestion

Anaerobic digestion (AD) is the bacterial breakdown of biodegradable organic material in the absence of oxygen. One of the end products is biogas, which is combusted to generate electricity and heat, or can be processed into renewable natural gas and transportation fuels.

According to the American Biogas Council, the U.S. has more than 2,200 sites producing biogas in all 50 states: 250 anaerobic digesters on farms, 1,269 water resource recovery facilities using an anaerobic digester (~860 currently use the biogas they produce), 66 stand-alone systems that digest food waste and 652 landfill gas projects. For comparison, Europe has more than10,000 operating digesters and some communities are essentially fossil fuel free because of them. AD is by far the most successful of the waste conversion technologies and will continue to grow in popularity and use.

With the resurgence of interest in waste conversion technologies the future looks bright for energy and chemical creation from waste resources for which we currently have no markets.

Gene Jones is the Executive Director of the Southern Waste Information eXchange, Inc. (SWIX) (Tallahassee, FL), the organizer of the Waste Conversion Technology Conference & Trade Show. The above-mentioned technologies, as well as other thermal and non-thermal technologies, will be discussed next year at the Waste Conversion Technology Conference & Trade Show, which will take place from June 2 – 4, 2019 at The Borgata Hotel Casino & Spa in Atlantic City, NJ. For more information, visit https://wasteconversionconference.com. Gene can be contacted at (800) 441-7949 or by e-mail at [email protected].