Every day we are becoming more and more aware of the damage we have done and are doing to our environment by not recycling and by not practicing conservation. It is up to all who have the power to develop technologies and/or implement waste solving technologies to make the effort no matter what the price, because we cannot afford the cost.

Tony Nocito

The waste industry: landfilling, reduce, recycle, reuse, composting, landfill mining, waste-to-energy facilities, recapturing methane gas, ocean dumping and hazardous-toxic waste landfill storage. Before moving forward I want to discuss the difference between price and cost: price is the price we pay, upfront for a product or service. Cost is what the product costs us to maintain that product or service over its life. Therefore the final price of a product includes the cost.

A simple example of this is the purchase of an automobile. We may purchase the automobile at $30,000.00, but we must maintain that automobile with monthly finance payments; which includes interest, insurance and a maintenance schedule (i. e. oil change, battery replacement, tune-ups, tire replacement, etc.) or the end cost that could be double of the price, if not more. We don’t think about the full cost when we buy an item, only the price. Waste disposal is a good example. As long as we can get rid of the waste, the price doesn’t matter.

Excess Waste

In the U.S. we landfill 250 million tons of trash each year. How long can we last with this amount of trash being sent to a landfill each year? Think about this: when you buy from McDonalds or any fast food restaurant, you may order any number of meals, along with a drink. If it is a quarter pounder with cheese meal, it would be packaged in a cardboard box the size of the quarter pounder, french fries in another box, depending on the size of the order, medium or large and a waxed container that would hold a drink with a plastic top and a straw with paper wrapped around for sanitary reasons, along with napkins. All of the aforementioned are not recycled, but put into the trash.

There are 33,000 McDonalds’ locations worldwide, McDonalds sells 75 hamburgers every second; McDonalds consumes 1 billion pound of beef each year, at the cost of five and half million head of cattle (think about the carbon footprint taken up by these cattle).

Although McDonalds has a program for buying recyclable cardboards, recycling its cooking oil, and recycling corrugated cardboard behind the counter, the after counter packaging is left for the garbage. The reason that the meal packaging cannot be reused, according to McDonalds’ website, “is that food packaging is not widely accepted by recyclers.”

Although McDonalds saves about 35 percent of its waste by recycling corrugated cardboard and cooking oil, it is landfilling 65 percent of its after counter waste. McDonalds and other fast food restaurants must find ways to develop technologies (Noah’s Ark) to help reach 100 percent of a waste recycling program after the waste leaves the counter in order to reduce the use of landfill space. Without question they certainly have the funds and the ability to pay for its development.

Landfill Progress

As we are clearly starting to understand, landfilling is becoming a major issue and public nuisance, because of landfill fires, landfill odors, underground water table contamination, methane gas leaks, illegal substance dumping, and the eyesore of a high pile of garbage. Granted, landfills are starting to make progress in certain areas, such as:

- Dumping a load before it is landfilled to check for and remove recyclables and natural resources

- Landfill mining to capture recyclables and valuable natural resources that can be recycled and reused, realizing that natural resources are starting to dissipate with population growth

- Realizing the importance of putting waste-to-energy plants on the landfill to reduce waste and produce needed energy while mining the landfill

- Capturing and reuse of methane gas to be used in vehicles

These landfill efforts are technologies/Noah’s Ark that continues to improve and support our environment.

Mandatory Recycling

The aforementioned indicate the progression of landfilling, but given the situation and the massive amount of garbage we create each year, recycling must become mandatory in the U.S. at all costs, as it is mandatory in the European Nations.

The price of landfilling garbage is cheap, but the cost to maintain a landfill is very high. Landfills require constant monitoring for methane gas odors and other odors, such as Hydrogen Sulfide, as well as greatly adding to the carbon footprint. A closed landfill and Superfund sites, once closed and capped, have to be monitored for at least 30 years partially paid for by the owner, if the owner is not in business, then the taxpayers pay. Usually the taxpayers end up paying.

The aforementioned long-term cost should be an enormous incentive for the taxpayer to participate in and demand mandatory recycling. According to the EPA, all landfills will fail and “By Definition, All Environmental Liabilities Involve Future Costs.”There are mandatory recycling regulations in individual states, but there are no national recycling regulations; however, the European Nations have had mandatory recycling regulations since the early 1990s.

So, why does the U.S. not have mandatory recycling laws? They are certainly a sustainable way of reusing waste, a sustainable cost incentive; provide a great reduction in the carbon footprint and, more importantly, a sustainable way of life. Our future strongly depends on finding better ways to reduce, recycle and reuse by the use of or invention of technologies/Noah’s Ark, creating a circular economy.

Look at the recycling statistics in the sidebar. If we implement those with the sufficient funding to further develop technologies quickly, it could sustain us for a long time and tremendously cut our carbon footprint. Then there would be two remaining apocalypse scenarios: ocean, lake, river and estuary dumping and hazardous/toxic waste landfilling.

Apocalypse #1

Marine debris, oil spills and ocean acidification are complicated and serious problem for our waters, and most importantly, our marine life and our life. Human beings have been dumping waste in water, including the ocean, since before the Agricultural Age. The Industrial Age brought with it new materials to dump, chemical wastes and by-products. Some materials are dumped into rivers and find their way to the ocean by running downstream. Other materials are dumped directly into the ocean from boats. Plastic is a harmful pollutant that does not break down easily in the ocean. Plastic accounts for 90 percent of all floating materials in the ocean.

The U.S. government has implemented the Ocean Dumping Ban Act of 1988 that makes it unlawful for any person to dump or transport for the purpose of dumping, sewage sludge or industrial waste into ocean waters after December 31, 1991 and provides for the payment of special fees for dumping and any penalties incurred by a dumper to be deposited into certain funds for use in finding alternatives to ocean dumping.

Ocean dumping, sewage system, road and field run-off into our waters has become a disaster and is very difficult and time consuming to clean- up, but the biggest problem in the ocean is dumped plastics that take a long period of time to break down. Plastics are killing our birds and our sea life because as the plastics break down into microplastics that the birds and fish believe are food. Eating these plastics will eventually clog-up the birds and fish’s digestive system, causing death.

The Ocean contains four large garbage patches, the Western Garbage patch, the Subtropical Coverage Zone, the Eastern Garbage Patch and other Gyres with Marine Debris. With the polluted oceans and water ways being a massive cleanup project, the question I have is when we bring the waste out of these oceans and water ways what are we going to do with it, i.e. landfill it, or incinerate it? We certainly do not have enough landfill space for all the debris. This cleanup project is a herculean task that will take years and the development of a multiple of new technologies/Noah’s Arks.

Human beings have been dumping waste in water, including the ocean, since before the Agricultural Age. The Industrial Age brought with it new materials to dump, chemical wastes and by-products. Some materials are dumped into rivers and find their way to the ocean by running downstream. Other materials are dumped directly into the ocean from boats. Plastic is a harmful pollutant that does not break down easily in the ocean. Plastic accounts for 90% of all floating materials in the ocean. Whether you call it trash, garbage, or just plain litter, marine debris is a serious threat to the world’s waters.

Apocalypse #2:

The second apocolypse scenario and the one we are going to concentrate on in this article is the fact thathazardous/toxic wastes are materials that are ignitable, reactive, corrosive or toxic to human health. Treatment of hazardous waste is stabilization and solidification, recycling, disposal in isolated areas of landfills, incineration and pyrolysis. The latter two require very high temperatures. The above covers the treatment and/or storage of most hazardous wastes. Please keep in mind if the hazardous waste cannot be recycled, such as lead and acids from batteries, they are sent to a regulated landfill. The generator or owner who is storing the waste owns it under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), revised as Superfund. CERCLA requires a treatment that permanently and significantly reduces:volume, mobility of hazardous substance and stops toxicity.

One such hazardous material is asbestos. Asbestos lawsuits permeate our courts and have created a multimillion industry for the legal firms. Unfortunately there are billions of tons of asbestos that will permeate out environment for century’s to come. 125 million people are exposed to asbestos in the work place each year, around the world someone dies of an asbestos related disease every five minutes and more people die from asbestos illnesses each year then are killed in road accidents. There is no safe exposure to asbestos that causes the deadly lung cancer Mesothelioma and a variety of other asbestos related illnesses. Given all that is known about the deadly dangers of asbestos, the generators/owners keep landfilling it because the price is cheaper than permanently destroying it and removing any future liability.

Climate change has become obvious, causing massive forest fires, droughts, high winds, floods, mudslides, hurricanes and tornados. It is only a matter of time before a fluid, hurricane and/or a tornado rips through a landfill cell with toxic waste or asbestos, spreading these toxins for miles. Industry leaders must constantly and consistently seek out or invest in ways to rid our environment of these dangerous toxins.

Destroying Asbestos

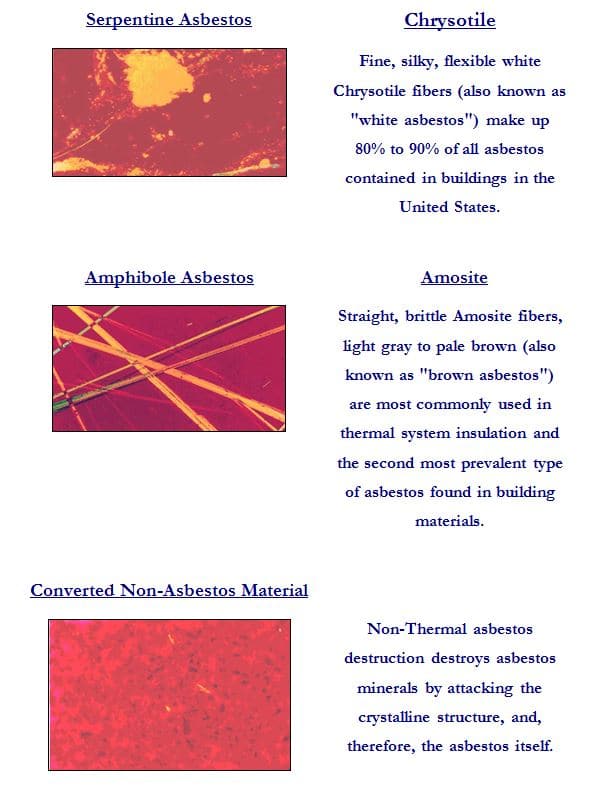

There are two families of asbestos mineral: Serpentine, which is Chrysotile and Amphibole, which is Amosite, Crocidolite, Actinolite, Anthophylite, and Actinolite (see Figure 1).

Asbestos does have several destruction technologies that destroy asbestos. Two are high temperature and one is non-thermal. The high temperature processes destroys the asbestos at 2500 degrees F. They are Vitrification and Hearth Oven. They require complicated scrubber systems to limit emissions and a great amount of electrical energy to operate, requiring highly skilled labor to operate these plants. Two other issues are the waste reduction volume is not great and if the treated asbestos is not totally destroyed at the end of the throughput, it must cool down before it can be checked for complete asbestos destruction. If asbestos is found not destroyed in a batch, that batch must be run through the process again. Both of these processes are EPA approved.

The third process, which is a non-thermal process, is EPA approved, simple to operate, does not require high electrical use and is operated by accredited asbestos workers and one lab technician who can read a polarized microscope. This process, unlike the high temperature processes is built mobile, transportable and sized to meet the client’s needs. It also reduces waste volume by 30 to 50 percent; most importantly, asbestos destruction is verified through process, therefore no asbestos leaves the process undestroyed.

All three asbestos destruction processes require shredding of asbestos containing material. Not all asbestos containing material can be put through a shredder to be treated asbestos free. The thermal processes leaves an asbestos containing material untreated like pipe or any other materials that cannot be put through the shredder, because they will do harm to the shredder. Whereas the non-thermal process proprietary chemical formulas was granted EPA approval to wash any asbestos containing material asbestos free that could not be shredded.

The non-thermal process is first shredded through the primary enclosed shredder and then screw conveyed in an enclosed screw conveyor into a finer secondary shredder for further size reduction up to a ¼ inch (note: both shredders are equipped with aerating water spray nozzles to keep the asbestos wet at all times). From the secondary shredder, the ACM is slowly fed by enclosed screw conveyor into the specially designed primary mixer that has been pre-charged with the proprietary conversion chemical. The primary mixer is equipped with an inverter and amperage meter to properly operate the speed of the mixer. Please note that asbestos is kept in an aqueous solution at all times. The primary mixer has a special blade tolerance to avoid jamming, because of the inconsistencies of the asbestos containing material.

The primary mixer is started at a slow inverter speed while the allowable amount of asbestos is fed into the primary mixer. Once the asbestos containing material is 95 to 98 percent destroyed in the primary mixer, it is pumped into the secondary mixer. When the asbestos containing material is verified to be completely destroyed, it is pumped into a settling tank to allow the solids to settle out and the proprietary chemicals to be siphoned off and reused. The remaining solids are pumped into a specially built cement mixer for neutralization and recycling.

Because no asbestos containing material leaves the non-thermal process before it is verified non-asbestos, the non-thermal process is time saving, electrical cost saving, environmentally friendly and the verification that no asbestos has left the process before destroyed. It meets the EPA required final testing for conformation of asbestos destruction by Transmission Electron Microscope (TEM) as required by 40 CFR 61.155—Standard for Operations that convent Asbestos-Containing Waste Material into Non-Asbestos (Asbestos-Free) Material.

Making the Effort

As human beings, every day we are becoming more and more aware of the damage we have done and are doing to our environment by not recycling and by not practicing conservation. I will leave you with this thought from a Wall Street Journal Salt and Pepper cartoon from 16 years ago: The scene is of a father sitting on a couch and his son standing in front of him. The father is looking at the son’s report card with great despair and disappointment, obviously expressing his opinion about the report card to the son. The son could not have given a better answer to his father for not receiving better grades. His answer: “If your generation doesn’t learn to save the planet, it won’t matter if my generation can’t read or write.

16 years later has become truer and truer. It is up to all who have the power to develop technologies and/or implement waste solving technologies to make the effort no matter what the price, because we cannot afford the cost.

Tony Nocito is Managing Member of ABCOV® Companies (New York, NY). He has been self-employed in the construction industry all of his adult life. For the past 30 years Tony developed and commercialized the unique ABCOV® system, bringing the ABCOV® process of asbestos destruction to full commercial availability. He has also been developing a process that changes Hexavalent Chromium in soil to Trivalent Chromium in soil, as well as a process that reduces off-specification and overburden blow and Batt fiberglass insulation, reducing the waste to 10 percent of its original volume, which will save a tremendous amount of landfill space. Tony can be reached at (212) 571-9125 or via e-mail at [email protected].

Figure 1

Before and after asbestos destruction.

Figure courtesy of ABCOV®.

Sidebar

Recycling Statistics: (Wikipedia)

- 251 million tons of trash in the United States

- 53.4 percentage of all paper products recycled in the United States

- 32.5 percentage of total waste that is recycled in the United States

- 100 approximate percentage of increase in total recycling in the United States during the past decade

- 8,660 number of curbside recycling programs in the United States in 2006

- 8,875 number of curbside recycling programs in the United States in 2003

- 95 percentage of energy saved by recycling an aluminum can, compared with manufacturing a new one

- 4.6 pounds of trash per person per day in the United States (most in the world)

- 1.5 pounds of recycled materials per person per day in the United States

Sidebar

Final Disposal of Hazardous Waste (Wikipedia-Hazardous Wastes)

Historically, some hazardous wastes were disposed of in regular landfills. This resulted in unfavorable amounts of hazardous materials seeping into the ground. These chemicals eventually entered natural hydrologic systems. Many landfills now require countermeasures against groundwater contamination, an example being installing a barrier along the foundation of the landfill to contain the hazardous substances that may remain in the disposed waste. Currently, hazardous wastes must often be stabilized and solidified in order to enter a landfill and many hazardous wastes undergo different treatments in order to stabilize and dispose of them. Most flammable materials can be recycled, used as industrial fuel. Some materials with hazardous constituents can be recycled, lead acid batteries are one example.

Recycling

Many hazardous wastes can be recycled into new products. Examples might include lead-acid batteries or electronic circuit boards where the heavy metals these types of ashes go though the proper treatment, they could bind to other pollutants and convert them into easier-to- dispose solids, or they could be used as pavement filling. Such treatments reduce the level of threat of harmful chemicals, like fly and bottom ashwhile also recycling the safe product.

Portland Cement

Another commonly used treatment is cement based solidification and stabilization. Cement is used because it can treat a range of hazardous wastes by improving physical characteristics and decreasing the toxicity and transmission of contaminants. The cement produced is categorized into five different divisions, depending on its strength and components. This process of converting sludge into cement might include the addition of pH adjustment agents, phosphates, or sulfur reagents to reduce the settling or curing time, increase the compressive strength, or reduce the leach ability of contaminants.

Incineration, Destruction and Waste-to-Energy

A hazardous waste may be “destroyed” for example by incinerating it at a high temperature. Flammable wastes can sometimes be burned as energy sources. For example, many cement kilns burn hazardous wastes like used oils or solvents. Today, incineration treatments not only reduce the amount of hazardous waste, but also they also generate energy throughout the gases released in the process. It is known that this particular waste treatment releases toxic gases produced by the combustion of byproduct or other materials and this can affect the environment. However, current technology has developed more efficient incinerator units that control these emissions to a point that this treatment is considered a more beneficial option. There are different types of incinerators and they vary depending on the characteristics of the waste. Starved air incineration is another method used to treat hazardous wastes. Just like in common incineration, burning occurs, however controlling the amount of oxygen allowed proves to be significant to reduce the amount of harmful byproducts produced. Starved air incineration is an improvement of the traditional incinerators in terms of air pollution. Using this technology it is possible to control the combustion rate of the waste and therefore reduce the air pollutants produced in the process.

Hazardous Waste Landfill (Sequestering, Isolation, etc.)

A hazardous waste may be sequestered in a hazardous waste landfill or permanent disposal facility. “In terms of hazardous waste, a landfill is defined as a disposal facility or part of a facility where hazardous waste is placed or on land and which is not a pile, a land treatment facility, a surface impoundment, an underground injection well, a salt dome formation, a salt bed formation, an underground mine, a cave, or a corrective action management unit (40 CFR 260.10).”

Pyrolysis

Some hazardous waste types may be eliminated using pyrolysis in an ultra high temperature electrical arc, in inert conditions to avoid combustion. This treatment method may be preferable to high temperature incineration in some circumstances such as in the destruction of concentrated organic waste types, including PCBs, pesticides and other persistent organic pollutants.