The increasingly stringent surface water discharge standards are an ongoing challenge for industries generating a wastewater stream. Deep injection wells should be considered as a potentially viable option for long-term, cost-effective wastewater disposal. However, they can generate considerable public concern and pushback during the permitting phase.

Bruce Clark, PE, Monte Markley, PG and Somshekhar Kundral

Understanding the entire range of wastewater management and disposal alternatives can be a daunting task, particularly as increasingly stringent surface water discharge standards take effect. Former solutions are no longer options or may be too costly. One alternative that is rapidly gaining traction is deep injection wells.

Deep injection wells (DIW) mean different things in different parts of the country. In the mid-west, DIWs have been used for decades to dispose of water generated from oil and gas production activities and are from 3,500 feet to more than 10,000 feet deep. In Florida, DIWs also have been used since the 1960s; however, they are used to dispose of treated municipal wastewater, unrecyclable farm effluent, and in some cases landfill leachate. DIWs in Florida range from 1,000 feet to around 4,500 feet deep.

This article reviews what constitutes a DIW, their general features, their cost relative to other wastewater management alternatives, and the range of industrial wastewaters suitable and safe for disposal. Public and environmental organizations can create challenges for DIW developers sometimes based on misinformation, but strategies presented here are helpful in getting consensus from stakeholders.

Deep Well Features

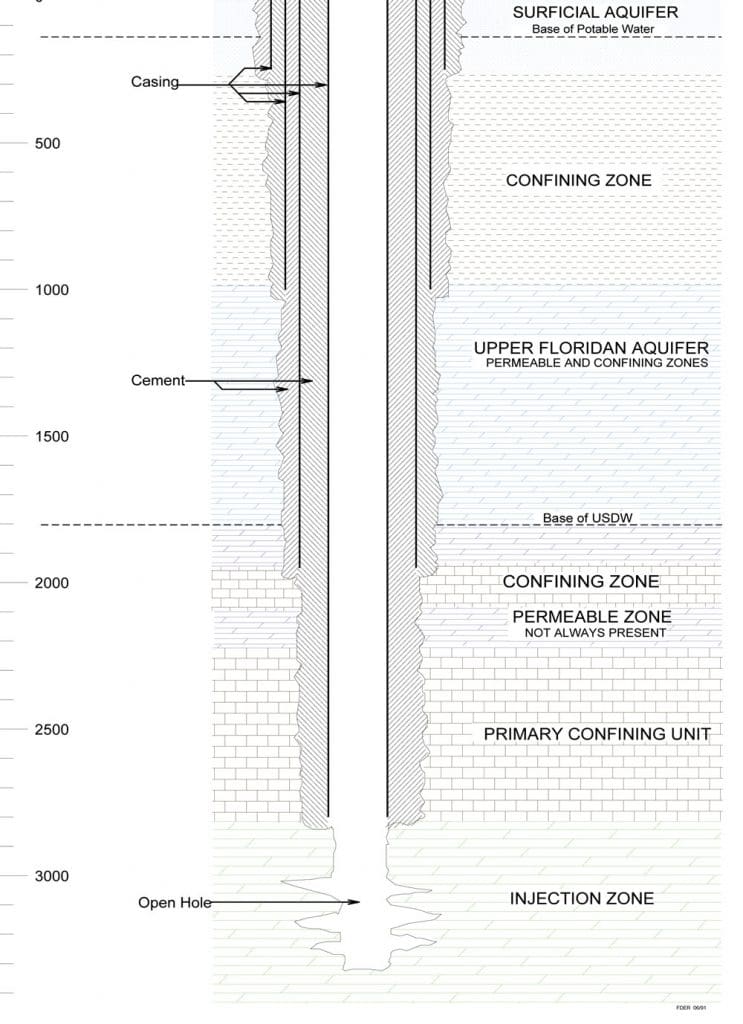

A DIW construction is a series of casings set in the ground where the initial casing starts out large, and subsequent casings become smaller in diameter, progressively telescoping downward. Casing materials are typically steel alloys or fiberglass for better chemical resistance. As a casing is set and rock is drilled out, the next casing is set and cemented with a chemically resistant grout. The process continues with each progressively deeper casing. These redundant “seals” are what keep the injected liquid from escaping into the protected aquifers.

The number of zones of protected waters, or aquifers, that the well will penetrate in order to get to the injection zone determines the number of casings. The inner casing, called the injection tube, extends to the injection zone. Mechanical packers seal the space between the injection tube and the last casing with the annular space. The resulting annular space is filled with a non-corrosive fluid. This fluid is put under pressure to demonstrate the continuous mechanical integrity of the well. The annulus is monitored for leaking, which would register as a loss in pressure and promptly stop the injection. Figure 1, is a simplified view of a DIW casing system used in south Florida.

Vertical turbine pumps work in conjunction with a holding tank, which is a used to smooth out the fluctuating flow of the wastewater feed pumps, and propel the liquid down the well. EPA and state regulatory agencies determine the pretreatment required for disposing of industrial wastewater. Municipal wastewater effluent is regulated differently and must receive at least secondary treatment before injection.

In the Midwest, DIWs are constructed to the same EPA criteria with a wide range of operating conditions. Some wells take fluid under gravity with no pumping, while others require higher pressure pumps that exceed 2,500 pounds per square inch (psi) for injection. This article will focus on wells used in Florida and typical fluid types and operational parameters.

Hydro-Geological Character of the Region

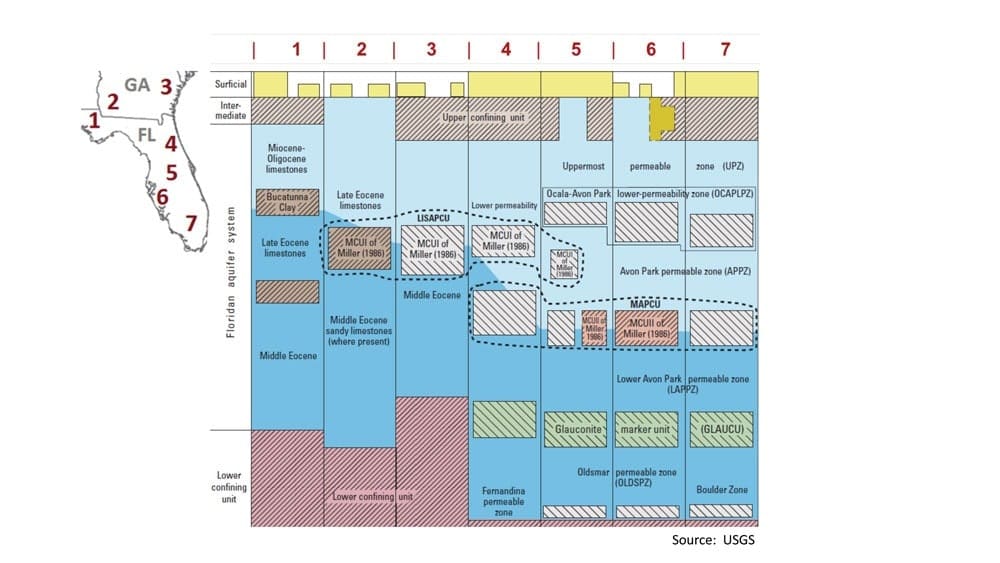

In central and south Florida, the injection zone lies below the underground sources of drinking water (USDW), which is the depth at which water with a total dissolved solids (TDS) concentration exceeds 10,000 parts per million (ppm) or the “10,000 ppm line”. This water is considered to be unusable in the future as a drinking water source. In parts of Florida, the injection zone is dolomite overlain by a series of confining units up to 1,000 feet thick made up principally of limestone with permeability several orders of magnitude less than the injection zone.

In central and south Florida, the target injection interval is the “Boulder Zone,” reportedly named because drilling into the formation often broke off pieces of the formation and made drilling difficult. The Boulder Zone is also known as the lower portion of the Floridan Aquifer. Later down-hole imaging technologies revealed this zone to be characterized by highly fractured bedrock and large karstic caverns, and the ability to inject relatively high flow rates with relatively little backpressure. It is not uncommon for Florida DIWs to have well flow rates exceeding 15 million gallons per day (MGD) and backpressures ranging from 30 up to 100 pounds per square inch (psi). The outlet for this zone is thought to occur dozens of miles off the coast in the Florida Straits.

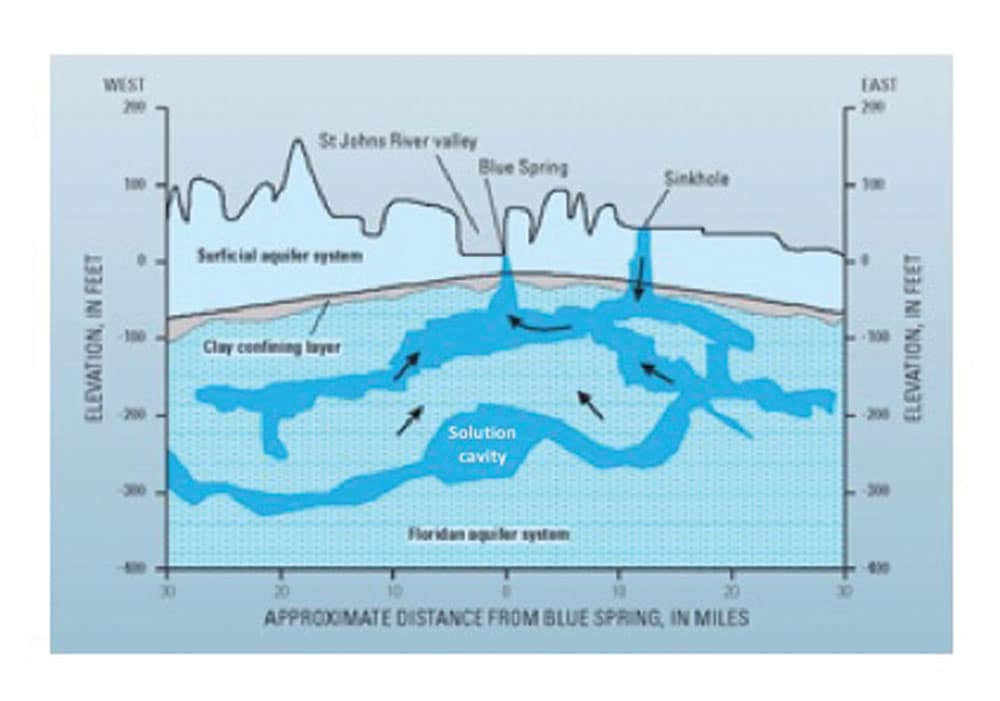

Florida also is blessed with 27 “first-order” or major freshwater springs, some of which became the prime attraction for many well-known tourist destinations, such as Silver Springs in central Florida, and Homosassa Springs in west-central Florida. All major springs originate in the Upper Floridan Aquifer (see Figure 2). These springs become major flashpoints with the public when a DIW is proposed in the vicinity of a spring. Looking at Figure 3, one can see the concern. The springs and target injection zone of the DIW, the latter in the Lower Floridan Aquifer are vertically separated by confining and semi-confining rocks. Although the confining rocks are hundreds to thousands of feet thick, their integrity to contain the injected wastewater, and by inference to contaminate the spring or the USDW, is always called into question by people opposed to the well. Most major springs in Florida have water quality issues, but the source of that has not deep injection wells.

Wastewater Compatibility

The versatility of the DIW in Florida to accommodate numerous different types of wastewater is an advantage. DIWs are being used on a large variety of waste streams that continues to expand, including:

- Treated Municipal wastewater

- Landfill leachate

- Contaminated Groundwater (i.e., ammonia – impacted)

- Reverse osmosis treatment concentrate

- Fish farm wastewater

- Various industrial wastewaters

Any wastewater considered for disposal must be compatible with the target formation and the final casing material. Therefore, depending on the wastewater, it may be straightforward to use existing industry references to confirm compatibility. In some cases, laboratory bench tests may be necessary to confirm compatibility.

Compatibility also includes the potential for creating unwanted microbial growth and scale formation within the injection interval. Growth and scale can happen with effluent containing sulfur or ammonia, two food sources for microorganisms or wastewaters supersaturated with minerals. Unless planned for and evaluated properly, both of these items have the potential to clog the formation around the well, significantly reducing flow and increasing back pressure. This can result in higher energy costs, regulatory action and significant, unplanned costs to rehabilitate the well.

Another significant aspect of municipal wastewater is that it is primarily composed of freshwater and thus when injected into the highly saline Boulder Zone or similar saline zones, will tend to have a vertical migration component because of the density difference and greater buoyancy than the target zone. A few wells have been taken out of service because the seals designed to prevent this migration failed and allowed wastewater to seep upwards into the USDW.

Protection of Drinking Water

The U.S. EPA Underground Injection Control (UIC) program is designed with one goal: protect the nation’s aquifers and the USDW. There are several protective measures in a DIW that are intended to meet this objective:

- Proper design of the well casings and injection tubing for strength and chemical compatibility. These components are recertified every five years with a robust mechanical integrity testing program.

- Demonstration that there is a confining zone of low permeability rocks to prevent upward migration of injectate. This demonstration includes documenting that any other nearby wells or borings drilled into the confining zone have been properly completed or plugged to prevent a short circuit contamination pathway

Testing the injection interval to prove it can accept the fluids at the proposed rates and pressures.

Continuous monitoring of the well pressures and flows that include the well annulus monitoring.

Frequent sampling and reporting of the injected fluid.

Financial assurance via various means to plug and abandon the well if required.

Operational Risks with Deep Injection Wells

The U.S. EPA conducted a study from 1989 to 1991 of health risks comparing other common and proven disposal technologies to deep wells injecting hazardous waste. The U.S. EPA concluded that the current practice of deep well injection is both safe and effective, and poses an acceptably low risk to the environment. In 2000 and 2001 other studies by the University of Miami and U.S. EPA, respectively, suggested that injection wells had the least potential for impact on human health when compared to ocean outfalls and surface discharges.3 William R. Rish examined this issue more closely using probabilistic risk assessment and fault tree analysis. Rish’s goal was to provide an objective and quantitative analysis of the risk of waste isolation loss from wells injecting hazardous wastes (Class IH), allowing meaningful identification and comparison of waste isolation subsystems as contributors to that risk. Seven failure initiating events were examined, including four mechanical failures, two breaches of the confining units and the accidental withdrawal of wastes. The overall risk was quantified by Rish as from 1 in 1 million (10-6) to 1 in 100 million (10-8).4 As a comparison, 10-6 is the same risk level used by EPA for contaminants in soil or groundwater that are a known human carcinogen.

There are several studies in Florida conducted by researchers and practitioners in the deep injection well field to assess the actual potential for municipal wells to contaminate the USDW. The maximum identified risk associated with injection well disposal of wastewater in south Florida is the potential migration of wastewater to aquifer storage and recovery (ASR) wells in the vicinity of injection wells (Bloetscher and Englehardt 2003; Bloetscher et al. 2005).

In a 2007 study, 17 deep wells in south Florida, used for municipal waste disposal, that had known upward migration into the USDW, were evaluated to develop a computer model to simulate these phenomena and extrapolate vertical migration over longer time periods. The results indicated that the measured vertical hydraulic conductivities of the rock matrix would allow for only minimal vertical migration. Even where vertical migration was rapid, the documented transit times are likely long enough for the inactivation of pathogenic microorganisms.5

In a 2005 study of 90 South Florida deep injection wells, the authors took actual field data and constructed a computer model calibrated to actual operating conditions. The intent was to model performance of two injection wells in the City of Hollywood, FL that the authors were familiar with and to determine the likelihood of migration, and what might stop that migration. Density differential and diffusion were likely causes of any migration. No migration was noted in Hollywood’s wells. The preliminary results indicate that Class I wells can be modeled and that migration of injectate upward would be noticed relatively quickly.

Stakeholder Engagement

Undoubtedly, a significant risk today in use of a DIW is public reaction. The public has become more sophisticated and is typically joining with various environmental groups, some well known and established, and some that may have been created in response to a proposed DIW. As an operator or business owner, you may be unfairly associated with oil and gas operators or other non-related environmental issues. As an example, the spike in earthquakes in the past few years in an area of Oklahoma are a result of injection of oil and gas produced liquids. Again, to a layperson they are likely to see that problem as potentially occurring on your project. Moreover, whether they are right or wrong, you cannot ignore their concerns.

Preparation to address, mitigate and overcome these issues can be a critical success factor in your project planning and execution. This activity includes the development of stakeholder engagement and public relations plan and having the right folks manage and conduct the interactions with the public. It is up to you to explain the difference in a way they can be comfortable with and understand. Not every professional is equipped to strike just the right tone with the public. We will discuss that more in the next section.

Every DIW siting study and permit application is different. There are, however, some basic strategies to help diffuse some of the concerns to keep your project moving forward; the over-arching issue is that the period to gain public and the regulator’s trust is short. Without some level of trust and management of expectations between the developer, regulator and the public, obtaining a construction permit will be difficult. Keep in mind that every day you operate your primary business, be it a landfill, utility, land development or a manufacturing plant, the public is watching and listening to what you say and what you do with regards to environmental impacts from your facility.

Doing the right thing and gleaning public trust well before the DIW project comes up, starts to build a foundation of cooperation that can be positive for everyone and your DIW project. If your facility has had some major issues that were not managed well in the public’s eye, it just makes it tougher to sell the DIW project. So, it is never too soon to start building the trust of the public and regulators. Some strategic elements of a DIW project to consider include:

- Proactively plan for the public meeting process. Otherwise the hearing could become a “war zone” of sorts. Getting ready starts well before the hearing.

- Conduct a site screening study to score and rank possible sites for the DIW. It is always best to consider more than a single site to minimize the risk of not having your permit granted because there is only a single option. Aside from the proposed deep well itself, this is likely the next most problematic issue for the public to digest.

- Eliminate any site that would violate a list of “no-go” or site exclusion criteria. Exclusion criteria can include, proximity to natural springs, in areas with known geologic anomalies such as active or dormant sinkholes, geologic faults or hydrocarbon deposits, and proximity to sensitive land uses such as scenic or protected recreation areas with significant water bodies. Occasionally, the best hydrogeologic formation from the standpoint of the ease of which it can accept the projected flow and type of wastewater is often in conflict with one or more “no-go” factors, and an exception may have to be made.

- Hydrogeologic studies must be relevant and reasonably current. In rapidly developing areas some 10 or 15-year-old studies could be inaccurate or at least have their validity questioned. For example, a new mining quarry could alter the area’s hydrogeologic characteristics. Conduct new investigations to fill in any significant “holes” in the site and regional hydrogeologic profile.

- Determine the location and nature of abandoned wells or other potential pathways that might result in the spread of the DIW effluent beyond the target aquifer.

Public Meetings

Many projects could benefit from a public presentation. If you decide to make one or are required to make one, here are a few things to consider. Ensure that public presentations are rehearsed well ahead of time. You want to vet everything your consulting experts will say and all materials must be informative, in plain language, and backed by facts or science. Offhand remarks can be misinterpreted or needlessly scare the public.

Another faux pas inadvertently committed by some experts when confronted by conflicting data or a legitimate concern offered by the public is deciding to dig his/her heels in and refusing even to consider that person’s data or address their concern in a non-judgmental manner. Defensive responses drive a wedge between your team and the public and may give them an impression that you are inflexible and do not care about their concerns. You could win the technical battle and lose the permitting war. Acknowledge the data or concern and say you will look it over and you understand their concern, and you will get back to them to discuss it further.

There are some elements where a DIW developer may hesitate and pull back some with regards to how forthcoming they want to be with certain information. Most of us can understand there is not a perfect solution or technology for every environmental concern. Many wastewater treatment decisions are driven by the least expensive method that gets the job done. However, when you are in someone’s “backyard” they may see many other alternatives, some possible, some not for various reasons. The public does not see a technology that is more expensive as being infeasible. Have treatment/disposal methods and costs comparisons available to lend credence to your decision to use a deep well. Be sure to inform the public that every technology has an environmental impact.

Also keep in mind, when the project involves landfill leachate disposal, for example, some of the public pushback could be generated from displeasure with the landfill itself. If that is the case, you may have to consider a strategy that also includes addressing that issue. Again, it is your responsibility to present the facts with a demeanor that is neither threatening nor evasive. Moreover, you had better have done your homework by investigating alternative technologies and have the facts available. If you have not, you could appear biased to the public, and no amount of talking at that point will change their opinion. Be prepared to discuss and contrast the pros and cons of all relevant and viable technologies.

The most sensitive elements with DIWs seem to include those listed below, and you likely will have to address these in your presentation. Consider the following responses.

Well Failure

Acknowledge upfront that there have been past DIW problems or failures in the industry. However, many of the failures occurred many years ago, and many can be chalked up to bad siting, design and operational decisions. The actual number of failures today compared to the number of systems operating and the volume of liquid disposed of without problems is very small.

Sensitive Natural Resources

Acknowledge upfront the sensitive natural resources near your project, if applicable. Explain how you intend to protect these from undesirable impacts by the DIW. Do your homework; resources that may be inconsequential to you may be a big deal with the public. For example, a small or localized artesian spring.

The author was involved in a project that was to plug a state-owned artesian spring because its flow was degrading the water in the Everglades, a major source of drinking water for Miami, FL. When word got out, the public, focused on stopping the project, descended in droves on the spring, along with the local TV news station. Even though the spring water smelled of rotten eggs due to its highly mineralized nature, it was used for drinking by the crowd and was claimed to have cured many of their illnesses. Even though the state was acting to protect a far more critical resource (the Everglades), the crowd chose to ignore that aspect.

Some people may fixate on a certain natural resource, like a spring, and assume the deep well will pollute that resource. This is tricky territory for the developer to negotiate and keep the project alive. Despite the strides made in understanding aquifers, springs and other geologic conditions, there is still uncertainty, although small, to whether the impermeable rock layers contain natural cracks or fissures near the well that could become a conduit for wastewater to migrate into the spring.

How do you address this belief without turning the meeting into an “I am right, you are wrong” standoff?” There are two things you can employ: 1) presenting specific information that demonstrates this type of hydraulic connection does not exist and, 2) explaining the concept of risk and how it applies to the potential for the spring to be polluted.

For the use of site-specific data, you may have to do some looking. The USGS has an extensive library of research papers on freshwater and saltwater springs in Florida and other parts of the U.S. Data such as origin and hydraulics of spring waters, dye tracer studies conducted to understand surface sources into the spring, and historical flow rates and water quality data are available. You need to present a dimensional picture to show that you understand how all the data pieces fit together to convince naysayers.

The other element, risk, is tricky to explain. Technical people understand risk, lay people may not. For example, you may tell them that the risk of polluting the spring is 1 chance in 1,000,000 and the risk of getting killed in a car accident is 1 chance in 100,000 (a higher risk). The rationale is many people usually never consider themselves the one who might get killed. You might expect lay people to conclude that the well risk is very remote. However, they may also respond that they have no choice but to drive, but the risk of the new well is not necessary to take.

Another aspect that may be mentioned by those opposing this disposal method is to haul wastewater to a municipal treatment plants for disposal. This is also not a solution without risk. Consider in 2017 municipal wastewater treatment plants in the south and western portions of Florida dumped more than 500 million gallons of untreated or partially treated wastewater into coastal bays, as a result of two hurricanes. The risk of a hurricane hitting Florida is about one in four. That is a very high risk and the pollution potential from dumped raw sewage to directly harm people is high. The preferred rationale is that a lower risk disposal alternative, like a deep well, is necessary to reduce the chance of direct pollution.

Realize that the project opposition assume your well will eventually contaminate a natural resource. You likely will be challenged to prove that your well would not impact the resource. Of course, this level of certainty is not possible. You have to fall back on providing what the legal profession would term, “a preponderance of evidence” (i.e., the more convincing evidence and its probable truth or accuracy). Simply put, you build your defense, presenting comprehensive and relevant studies, and specific site data and information. Remember, you are also appealing to the regulator to consider your information and be impartial in its review before making recommendations. Close all gaps in your report so that all key information is presented informing both the audience and the regulators.

Well Leaks

Explain how leaks in the well could occur, how they are detected and how they can be mitigated before significant environmental impacts occur. Explain how your design has improved over past systems to reduce the potential for similar problems to occur.

Contingency Plan

Explain that, despite all of the engineering design, construction and operational safeguards built into the project, that the DIW could still develop a problem. For example, if the effluent had migrated from the injection zone and is potentially impacting a source of drinking water or a protected natural resource, you have to be prepared to shut the well down, at least temporarily, until resolving the problem.

You must be willing to commit that if evidence of the leakage occurs in the groundwater monitoring system or elsewhere, that you will take action to determine where the well is leaking and attempt to repair it. If the repair does not stop the leak, and evidence strongly suggests that the USDW would be, or is impacted, you should have a plan to develop another disposal source, and take the well offline and shut it done. Have a viable Contingency Plan ready for execution.

Building Trust with the Public

The public today has access to everything related to operating DIWs, especially wells that have failed or have had major operational issues, so you cannot ignore or downplay those negative incidents that have occurred. A lot of it is fact. Some organizations, such as the Center for Health, Environment & Justice (CHEJ) have compiled highly detailed publications that are designed to inform, mobilize and, ultimately, help environmentalist prevail in the struggle to thwart DIW projects.6

The author reviewed a CHEJ document entitled, “Deep Injection Wells – An Explosive Issue,” dated 2009.6 The document references some 58 cases (throughout the U.S.) where a deep injection well had a significant problem or failure that adversely impacted the environment. However, out of the 58 reference cases, only nine occurred between 2001 and 2009. The majority (49 cases or 88 percent) occurred in the 1970s and 1980s. Since then the regulations governing deep injection wells has been considerably strengthened. The industry has learned much from those past failures and the design, materials and installation technology have been improved.

In the same CHEJ report, there are more than a few instances where it is obvious that many wells that failed had very poor overall designs, and several more where the casing and the formation injected into was not compatible with the acidic wastewater that was being injected. Many also seem to be poorly sited and were operated when they should have been shut down. These collectively could be considered failures of the well owners and the regulatory agencies to enforce and abide by stringent standards on the wells. They certainly give the industry a black eye, but in the author’s opinion should not be used to condemn the technology.

Moreover, what about in Florida where “20 of the nation’s most stringently regulated disposal wells” claiming to have failed in the early 1990s, “releasing partly treated sewage into aquifers that may one day be needed to supply Miami’s drinking water,” as touted by ProPublica? No mention of those failures in the CHEJ report. The CHEJ mentions only one south Florida well that failed when evidence of injectate was picked up by a monitoring well.

So, the authors’ take on these reports is that they cannot be denied and are useful in that there are lessons to be learned from them that do not and should not have to be repeated. The noted failures are certainly regrettable and in a few, much older cases, border on what could be considered by some as rising to the level of criminal intent. However, adverse impact on people’s health as a result of these incidents is not indicated.

You can reduce the public’s concern that you may not be forthcoming by being upfront about these four aspects of DIW technology and systems. This is a huge step but is necessary to continue to build trust with the public. You can put yourself in a better position in which to keep advancing the project by diffusing these concerns early on. One other item that may be necessary to help put your project across the finish line is a public communications element. Ensure a qualified representative of your organization is reachable during the permit application review process and through the public presentation and hearings phase; keep your legal advisors involved. An effective communications program can nip minor concerns in the bud before they potentially escalate to your company being on the 6 o’clock news and wasting resources to correct and educate the public.

In public meetings, there is a lot more going on than meets the eye. Those in attendance bring their hopes, concerns, and fears. Do not expect any sympathy or support for your project. A typical turnout looks similar to that in Figure 4. Your team will be severely tested. You want to be prepared. Thus, it may be beneficial to engage a consultant to help you develop practice scenarios and coach your team on live practice sessions to provide focus, eliminate emotion, root out unintended bias and vague statements, and convey information in a way that the public can readily understand it.

Treatment Cost Comparison

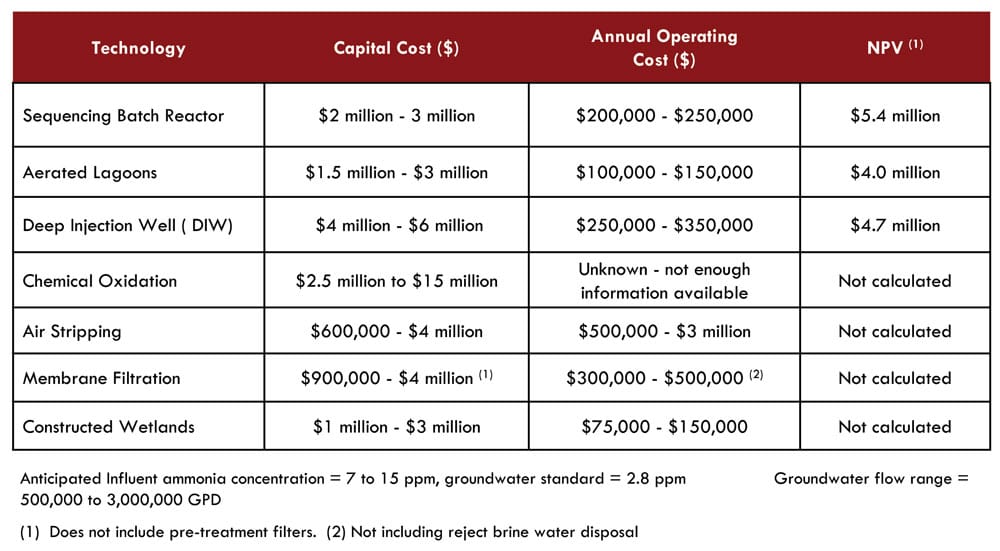

A deep injection well lifecycle cost compares favorably with other traditional waste treatment and disposal techniques. A lifecycle cost includes the capital cost and operating and maintenance costs for the useful life of the system. On a recent project, the wastewater for disposal was groundwater contaminated with ammonia nitrogen from a former landfill. The estimated groundwater recovery rate and DIW disposal rate was calculated to be 1.2 million gallons per day (MGD). The proposed deep well was designed to have a final casing of 12-inch diameter, an 8-inch diameter injection tubing to a depth of 2,950 feet, and below that approximately 550 feet of open bore hole. The lifecycle cost estimate comparison to other viable technologies is shown in Table 1.

In this case, there were no projected revenues, so the alternative with the lowest net present value (NPV) would technically be the preferred alternative. Even though the aerated lagoon option had the lowest NPV, it was ultimately judged too risky with a long break-in treatment period and significantly more space for treatment ponds needed.

Summary

The increasingly stringent surface water discharge standards are an ongoing challenge for industries generating a wastewater stream. DIW’s should be considered as a potentially viable option for long-term, cost-effective wastewater disposal, where a viable receiving geologic strata exists and when wastewater management alternatives are evaluated. In Florida, they currently provide an environmentally sound disposal option for many regions.

However, DIWs can generate considerable public concern and pushback during the permitting phase. The pushback is often due to the issue of the injected wastewater being in close proximity to the public drinking water source or other significant freshwater resource such as a spring. There also is concern that non-municipal wastewaters are not required to have significant pre-treatment before injection, thus increasing the perception that bacteria and other disease-causing organisms or potentially harmful chemical compounds may be present and could inadvertently be introduced into the drinking water system.

An owner should have a positive mindset to the back and forth natures of the regulatory review process. Be prepared to conduct proactive regulatory meetings, have complete, relevant and current technical studies including consideration of other well sites and disposal technologies, and a thoughtful and well-rehearsed public presentation(s) to develop your case to produce the best outcome.

Bruce Clark, PE, BCEE is a Project Director at SCS Engineers and can be reached at (813) 727-0541 or e-mail [email protected].

Monte Markley, PG, is a Vice President at SCS Engineers and can be reached at (316) 315-4501 or e-mail [email protected].

Somshekhar Kundral is Project Manager for SCS Engineers and can be reached at (305) 799-5875 or e-mail [email protected].