Eliminate the stress and surprises of purchasing a roll-off container.

By Meagan Daugherty

Purchasing roll-off containers can be stressful. From confusing specs to the first time you have to unexpectedly unload a trailer full of stacked and nested containers, there are many opportunities for frustration to arise. Let’s talk about how you can eliminate stress and any potential surprises by looking at the steps of purchasing a roll-off, including:

1. Your Truck + System

2. Spec-ing Containers

3. Requesting Quotes

4. Placing Your Order

5. Shipping + Delivery

6. Follow Up

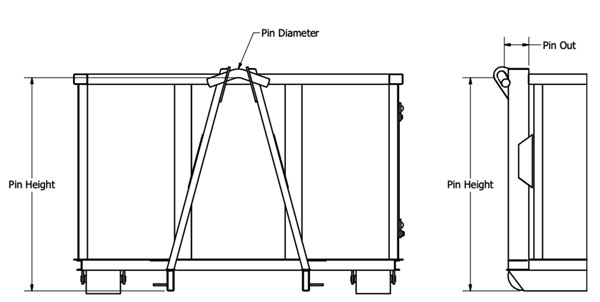

Graphic showing how to measure the pin height, also known as bail height, and pin diameter on a hooklift container to provide accurate measurements to the roll-off container manufacturer. Figures and Chart courtesy of Bucks Fabricating.

Your Truck + System

Roll-off container manufacturers will need to know if you have an existing truck or you are in the market to buy. This information is important to ensure the proper container hookup and dimensions are quoted to fit your truck and system. If you are in the market for a truck, the roll-off manufacturer can likely connect you with some truck dealers and upfitters to help you source the right truck for you. Here is what the roll-off container manufacturer will need to know about your roll-off truck in order to provide you with a quote:

- What is the make and model of the hoist system (not the truck itself)?

- Is it a cable style, hooklift, dino, Canadian hookup or a trailer style hookup?

- For a hooklift style, the following information will also be needed:

• Bail Height—The most common are 36”, 54” and 62”, but there are other options available depending on the brand. See Figure 1 on how to measure pin height and diameter.The type of stops/body hold downs—There are several types including outside bar, outside angle, outside tubing, inside pin, inside bar, inside pocket and more. Refer to your hoist manufacturer for more information on stops.

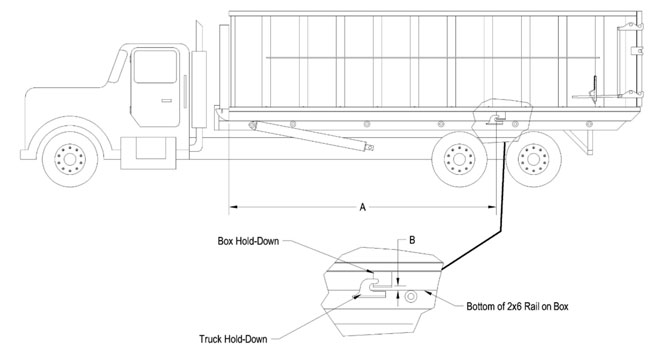

• The location of your stops/body hold downs—See Figure 2, on how to measure stop location.

• The type of stops/body hold downs—There are several types including outside bar, outside angle, outside tubing, inside pin, inside bar, inside pocket and more. Refer to your hoist manufacturer for more information on stop

How to measure the stop length on a hooklift container to provide accurate measurements to the roll-off container manufacturer.

Spec-ing Containers

The more you know about what you want and how you will use it, the more accurate your quote will be. To help the roll-off container manufacturer understand what types of containers you need, there are several things to consider:

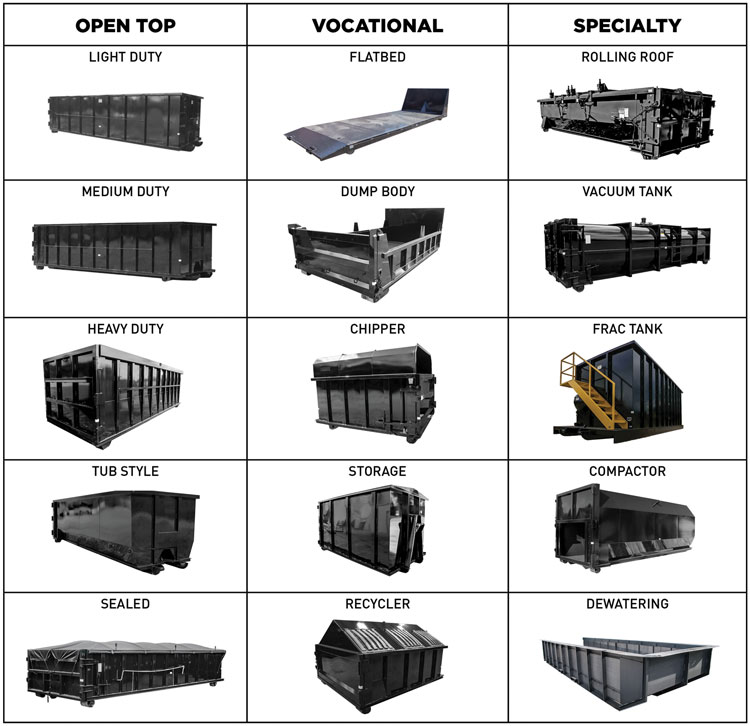

- Are you looking for an open top, vocational, or specialty style roll-off?—Chart 1, lists various roll-off container styles that can help you identify what type of container you need.

- Do you have a specific application in mind?—Letting the manufacturer know how you will be using the container will allow them to make recommendations for container types and features.

- Are there any features or custom options that you would want added to the container?—Manufacturers offer many options including tarps, various tailgate styles and more.

- What color would you like the container?—In addition to their standard offerings, most manufacturers are capable of custom color matching when provided with a proper paint code. This may result in additional leadtimes and/or cost.

- Do you want branding on the container completed by the manufacturer?—A great option for rental fleets, some manufacturers may offer to have your logo and/or contact information placed on your containers with vinyl decals. This may result in additional leadtimes and/or cost.

Requesting Quotes

Whether it is your first time purchasing a container or you have been in the industry for a while, it is always a good idea to contact several roll-off container manufacturers to compare pricing, specs, leadtime and service. If you have purchased from a manufacturer previously, the quote process will be pretty smooth. More often than not, the purchase is for the same order as before and all of that information has been filed. If you are shopping around or getting your first ever quote, the process will take a little longer as they will all be asking the same questions that you may have answered several times before. It is important to be patient during this time as the more information they get on the first call, the more accurate your quote will be without the need to make additional edits.

Your decision may come quickly or may take a couple of weeks. When you receive more than one quote, be sure you are comparing apples to apples with specifications. Manufacturers often have different standard products. Here are some key differences to look for:

- Long Rails—Some manufacturers offer a standard 3/16” long rail, while others offer a ¼” long rail. The price for the roll-off with 3/16” long rails could be less depending on the other specs, but keep in mind that the long rails are the backbone of your container and choosing the stronger spec will benefit you in the long run.

- Floor Sheet—Do you see differences in the thickness of the floor sheets on your quotes? These could be simple differences in unit of measurement such as 3/16” versus 7ga, or they could be actual differences in thickness such as ¼” versus 3/16”. Make sure you understand the differences both in function and cost.

- Side Sheet—Another difference you may see in your quotes will be the side sheet. Similar to the floor sheet, they could be differences in unit of measurement, but also differences in thickness. This could change the function and the cost, so be sure you are comparing them when making the decision.

Prime + Paint Options—Does your quote include primer or is it only upon request? Are you getting a water-based topcoat or an alkyd enamel? Is it a complete paint on the container or just an external coat? - Leadtime—Manufacturers have standard leadtimes based on the current orders in-house, but may be able to accommodate a faster turnaround time when requested.

If you need a specialty container, you should expect a drawing that you will need to review and approve prior to the quote becoming a sales order. Depending on the number of custom features, the drawing could take some time, often ranging from two to 10 business days. Once you decide on the manufacturer, it is time to inform them that you are ready to move forward.

Placing Your Order

Some companies may require you to sign a quote before they turn it into a sales order. The sales order will include several items: the product description, quantity, price, estimated completed date, estimated ship date, terms and conditions, shipping information, and terms and conditions. Be sure to review all of this information prior to signing to make sure nothing was missed.

Once the sales order is signed, the container will be placed in the production schedule. You should receive updates on your container throughout the process, letting you know if your container is ahead of schedule or if there are any questions along the way that could cause any delay. Once the container is painted, it will cure and be stored in the yard. The manufacturer will then have the sales representative or shipping coordinator contact you to let you know that the container is complete and awaiting pickup or shipment.

The Shipping + Delivery

An important question that is commonly forgotten is shipping. There can be several options for the delivery of your containers based upon your location, order details and capability. More often than not, delivery will be by a tractor trailer, so it is important to make sure the delivery location can accommodate a truck of this size. The most common delivery options are:

- Delivery by Manufacturer-Owned Truck—With this option, the manufacturer will use their own truck(s) and employee(s) to deliver your order.

- Delivery by Common Carrier, Manufacturer Arranged—With this option, a third-party will be contracted by the manufacturer to deliver your order. The manufacturer will provide you with the contact information of the carrier. The carrier will be in contact with you regarding their estimated delivery day/time.

- Delivery by Common Carrier, Customer Arranged—With this option, you contract with a third party to pick up your order at the manufacturer’s location and deliver it to you. You will need to provide the carrier and manufacturer with proper contact information so that they can arrange the pickup at the manufacturer’s location.

- Customer Pickup—With this option, a customer will travel to the manufacturer’s location to pick up their order in person. This could be with a roll-off truck, a tractor trailer or other options. The customer will arrange the pickup day/time based on the manufacturer’s hours of operation.

Another factor to consider with shipping is the trailer configuration. It is common practice with roll-offs to consolidate freight by stacking/nesting containers so more units can be placed on one trailer. This is a great way to reduce shipping expense, but it is important to understand the challenges and responsibilities that arise with this shipping method. You can choose to have your order delivered without stacking. Not stacked orders are easier to unload and reduce risk of damage, but be aware that if a large quantity of containers is purchased, more deliveries will be required, which will increase your cost. Certain types of containers, such as those with sealed tailgates and any type of covering/roof can only be shipped in non-stacked loads.

If you agree to receive your order stacked/nested, make sure you are aware of the following:

- Open Top Rectangular style containers can be shipped in stacks of two to four units depending on dimensions. See Figure 3—This means you will need a piece of equipment onsite capable of moving the weight of an entire stack at once and then unstacking the units. Depending on your container type, this could be as little as a few thousand pounds but could easily exceed 30,000 lbs.

- Open Top Tub Style containers can be shipped nested in various quantities depending on dimensions. See Figure 4, page 36—Similar to a stacked configuration, you will need a piece of equipment and heavy capacity chain that will assist in removing a container. The chain is looped around the rails on one end and the fork truck on the other to drag the container separate from the rest until it is on its own and able to be lifted safely to the ground with the forklift.

- Some or all of your containers may have the tailgates removed and you will need to reinstall them before use—While installing tailgates can be a quick and simple process, it is important to understand your containers will not be ready for immediate use.

- Manufacturers are not responsible for damage to containers—When you agree to have your units stacked/nested, most manufacturers will have you sign a disclaimer stating that you understand that minor cosmetic damage can occur during the loading/unloading process.

- You are responsible for unloading your containers—There are many options for unloading containers, but be aware that you are responsible for having proper equipment onsite at time of delivery.

- Commonly used unloading equipment include forklifts, loaders, roll-off trucks and heavy capacity chains. To view videos of how to unload your new containers, you can visit https://bucksfab.com/shipping/.

Follow Up

A couple of days after your container has arrived at your facility, the manufacturer may contact you again to ask if the container has met your expectations. This is where you can tell them your feedback. If you are pleased, they may also ask you to provide a testimonial about your experience to use on the website, social media and other future marketing materials.

Are You Ready?

Now that you know everything to prepare for when ordering your roll-off container, it is time to put it to the test. Gather all of the information that the manufacturer will ask prior to making the call. You will be sure to surprise them. Be patient if you are asking for a specialty container as it may take some time to draw up. Review all of the information laid out on the quote and sales order before approving and signing to ensure both you and the manufacturer are on the same page. Wait for the call letting you know your container is completed and ready to get to work. Watch videos on how to safely unload the trailer once it arrives at your facility. Expect a follow up call to ensure that everything went smoothly. With 2020 coming to an end, give some manufacturers a call today and get started with a quote or two and start fresh with a new year and some new containers. | WA

Meagan Daugherty is the Communications Specialist for Deist Industries, Inc. (Hadley PA). She is responsible for connecting with end users, dealers and the general public through social media, newsletters, magazines, mailers, and more. Meagan can be reached at (724) 253-5055 or e-mail at [email protected].