For more than 30 years, the City of Beatrice, NE has used Brown Bear Corporation’s Windrow Aerator to help grow and efficiently run their operation.

Running one of the most clean and efficient composting operations in the U.S., the City of Beatrice, NE has been perfecting their process for more than 30 years. Located 40 miles south of Nebraska’s capital, Lincoln, the City of Beatrice is comprised of 12,500 people and the composting operation also serves seven counties in the area plus Northern Kansas—an overall population of more than 390,000. The operation was started in 1984 by the Waste Pollution Control Division of the Board of Public Works and was formerly housed at the Wastewater Treatment Facility (WWTF). Now, currently near the landfill, the operation continues to take the sludge from the WWTF and transport it to the compost site, where it is mixed with grass clippings and wood chips, and processed into composting material, which in turn is used by the city for the parks and trails, cover material for the landfill and side slopes as well as given back to the public. In addition, Campbell’s Nurseries and Garden centers out of Lincoln, NE have bought the compost in bulk as well as Earl May Nursery and garden in Beatrice, NE. In 2018, 5,478 cubic yards of material were used and consisted of 1,898 yards of biosolids from the treatment plant, 811 yards of grass, 829 yards of leaves, 1,005 yards of wood chips and 935 yards of sawdust.

Labor Intensive Operation

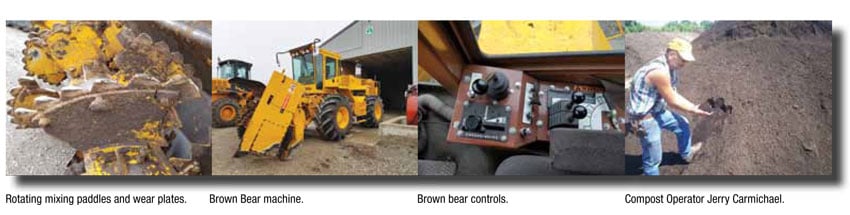

When the composting operation first started, it took two employees to go through the manual, labor intensive process that would take up to a week to complete. Jerry Carmichael, Compost Operator, who has been with the City of Beatrice’s composting operation for more than 30 years, says, “At that time, we were composting at the wastewater treatment facility using a truck mounted feed mixer. We would load our material into that and auger it back off, but it was very time consuming, so in 1991, we started looking at better ways of processing the compost.”

According to Carmichael, the operation’s former Supervisor, Bruce Bates, made the decision to look for equipment that would help them throughout the process. He ended up at an industry event in the area where he found Brown Bear Corporation’s Windrow Aerator 500. “When they first got ahold of us, they were doing a really labor-intensive operation and they asked us to bring over a machine and do a demonstration,” says Stan Brown, President of Brown Bear. “They actually were having other machines do demonstrations as well, but what really sold them on our machine was that it would run on unimproved surfaces; it did not have to be on a concrete pad. In fact, the day of our demonstration, it was cold and rainy and no one else was able to come out because they kept getting stuck and having slippage problems.” Bates decided to move forward with using Brown Bear’s equipment and the rest is history.

Brown Bear Corporation (Corning, IA) built their first tractor in 1976, getting into the waste handling side of the business in 1978 with an adaptation of a trench backfilling machine that was used for the underground pipe installation industry. At the time, Dr. Leon Chesnin, Professor of Agronomy at the University of Nebraska Lincoln had seen this machine and thought that it had potential in composting. While the University of Nebraska Lincoln was doing research in that area, Brown Bear loaned the University a machine to use for two summers, giving feedback and suggestions on how it could be improved. Now, with more than 30 years of experience, Brown Bear offers environmental solutions to composting, sludge drying, manure handling and bioremediation, as well as utility jobs, such as brush cutting, right-of-way clearing, tree trimming, backfilling and all-terrain transporting.

Making the Operation More Efficient

Since purchasing the first piece of Brown Bear equipment all those years ago, the process has not only been cut down from a two-man operation to a single operator, but with Brown Bear you also get much better mixing action. “The Windrow Aerator gets clear down to the bottom of your pile and mixes more thoroughly,” says Carmichael. “There was just no comparison between how we originally did things to what we are doing now. Before the machine, we were running continually five days per week and now with the Brown Bear, I can be running six to 10 rows of compost and re-mix that in a couple of hours twice per week.”

The city of Beatrice is now on their second Windrow Aerator, a replacement for the first one in 2006, and the new machine is still going strong. Brown explains that the different between the first one and this current machine is that the first one was 300 horsepower while this upgrade is 350. In addition, the first machine had a 39″ by a 12′ diameter paddle with a mixing paddle head on it and this one has a 49″ by 12′ mixing attachment. Since the attachment is bigger, the operation can develop and turn bigger windrows. “We had our first piece of Brown Bear equipment for 12 to 13 years but it was getting to the point where the parts were getting obsolete, so we updated to a new machine. The current one is still in very good condition and running well,” says Carmichael.

With regular upkeep and the proper use of the machine, maintenance is almost nothing. “We have done a couple of upgrades for them,” says Brown. “It does have parts that we call consumables—those that wear out on the mixing head. However, because Jerry is such an excellent operator and he doesn’t dig in the dirt or get it down to the concrete pad, the original set from 2006 is still on the machine.”

Still Going Strong

“Every town has a wastewater treatment facility,” comments Tobias Templemeyer, City Administrator for Beatrice. “You have to do something with the byproduct. By using the Brown Bear, it allows us to solve a couple of problems—address the sludge issue coming out of our wastewater treatment facility and it enables us to provide a service to our residents. With the Brown Bear technology, we mix the necessary material together, produce a compost and give it back to residents as a way of saying thank you. Our residents have really come to enjoy and like the compost that we provide. That is where we end up with the win-win in this situation.”

Dean Kelch, Chief Operator, agrees, “One thing that stands out to me since I’ve been working here is that Stan has brought people here from other places to show off his equipment because he likes to come our compost facility, which is so well maintained and the cleanest and nicest operation in the area, and this reflects back on Jerry since he handles that. Even though, he is working with biosolids and yard waste, he still finds ways to keep it looking great. I’ve had compliments from the public too about the cleanliness of the facility.”

As one of the cleanest, best run composting operations that Brown Bear is working with in this nation, Brown points out that they do everything right, “They are a first-class operation. All the people in the City of Beatrice have been great to work with and we have a great working relationship with all of them. They ultimately designed and built their composting system around the Brown Bear machine and when they built the current facility, they designed and built it around using the Brown Bear. They have had a lot of input on the features they would like to see on the machine. We have worked hand-in-hand together and as the operation grew, they didn’t need our help, but we’d volunteer it. They’ve got their act together. Our machine will run another eight to 10 years with no problems.”

Carmichael says, “Stan has been really good to us. It’s been a very good and rewarding experience. Brown Bear is the backbone of our operation. Without it, we couldn’t even begin to do what we are doing now. I’ve been doing this now for 33 years and it is the workhorse of the operation; it is what makes it possible. When the equipment needs to be replaced again, Brown Bear would be my recommendation.” | WA

For more information on Brown Bear Corporation, call (641) 322-4220 or e-mail s[email protected] or visit www.brownbearcorp.com.

For more information on the City of Beatrice, NE, contact Dean Kelch at (402) 228-5221 or e-mail [email protected].