By dedicating time and effort to the selection process, you can invest in a scrap handling magnet that meets your needs, enhances operational efficiency, and contributes to the overall success of your business.

By Sean Abenstein

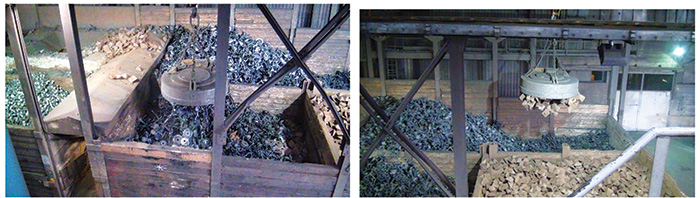

Investing in the right scrap handling magnet is a critical decision for scrap yard owners, recycling equipment buyers, port and railway service providers, and smelters. It can significantly impact the efficiency, productivity, and profitability of their operations. However, selecting the most suitable magnet requires careful consideration of several factors. In this comprehensive guide, we will provide a step-by-step approach to help you make an informed decision when investing in a scrap handling magnet.

#1: Determine Your Specific Requirements

The first step in selecting the right scrap handling magnet is understanding your specific requirements. This involves thoroughly evaluating the type and volume of scrap you need to handle. Consider factors such as weight, size, shape, and composition of the materials. Furthermore, assess the environment in which the magnet will be used, such as whether it will be operated indoors or outdoors, in a scrap yard, or at a steel mill. Also, take into account temperature variations and any special safety considerations.

By conducting a comprehensive assessment of your specific requirements, you can lay the groundwork for choosing a magnet that aligns perfectly with your needs and ensures optimal performance.

#2: Assess Lifting Capacity

Determining the maximum weight of scrap you intend to handle is a crucial aspect of selecting a scrap handling magnet. It is important to choose a magnet that can comfortably handle the desired weight range. However, it is advisable to opt for a magnet with a higher lifting capacity than your immediate requirements.

Investing in a magnet with a higher lifting capacity allows room for potential growth or unexpected heavier loads in the future. It ensures that your magnet will be able to handle increased workload without strain or compromising safety.

Consider the type of scrap you typically handle and its weight variations. If you primarily deal with lightweight materials, a magnet with a lower lifting capacity may be sufficient. However, if you handle heavier materials or anticipate growth in your operations, investing in a magnet with a higher lifting capacity will provide the necessary strength and flexibility.

#3: Consider Magnet Size and Shape

The physical dimensions of the magnet play a crucial role in its usability and compatibility with your existing equipment or machinery. It is essential to consider the available space in your facility or on your equipment where the magnet will be installed.

Furthermore, consider the machinery to which the magnet will be attached. Will it be suspended from a crane or mounted on a specific machine or material handler? Ensure that the size and shape of the magnet allow for convenient operation and seamless integration with your existing infrastructure. Factors to consider include the dimensions and weight with a full load of the heaviest material, as well as clearance requirements.

By carefully considering the magnet’s size and shape, both with and without a full load, you can ensure optimal functionality, minimize operational constraints, and enhance overall productivity. For example, you may ask yourself some of the following questions: Will the magnet fit into a commonly used container? Does the excavator have the necessary lifting capacity to safely carry the load? Can the crane lift the magnet, taking into account the dimensions of the load, up and over the side of a rail car or truck?

Addressing these questions will help you make informed decisions and ensure that the magnet’s size and shape align with your operational requirements. It will also help avoid any potential issues or limitations that may arise during the handling process. Proper planning and consideration of these factors will contribute to a smoother and more efficient operation of your scrap handling magnet.

#4: Evaluate Power Source and Control

Evaluating the power source and control mechanisms of your electromagnet is crucial. Start by assessing whether your facility or excavator has the necessary electrical equipment to support the magnet’s power requirements.

Consider the availability of electrical infrastructure and any additional equipment or modifications needed to ensure the magnet’s optimal performance. Evaluate the power supply’s voltage and current capacity to ensure it can meet the magnet’s electrical needs.

Additionally, assess the control options available for operating and controlling the magnet. Determine if you need manual or remote control, and whether the magnet requires specialized control systems for efficient operation. Consider factors such as control panels, safety features, and compatibility with your existing control setup.

Vehicle-mountable power options come in various forms, primarily falling into two categories: diesel or hydraulically driven generators. Diesel generators are self-contained and run off a dedicated diesel engine, whereas hydraulic generators use the existing hydraulics of your excavator, material handler, truck, or skid steer.

Taking the time to evaluate the power source and control mechanisms will ensure seamless integration of the magnet into your operations, preventing any potential issues and maximizing efficiency.

#5: Assess Durability and Maintenance

Durability and maintenance are critical considerations when investing in a scrap handling magnet. Look for a magnet that is built to withstand the demands of your operating environment. Consider the type of shell, whether it is cast or fabricated. A magnet with a robust cast shell construction tends to offer superior durability and longevity. While fabricated magnets offer less durability, they are also more economical and lighter. If being used for a light workload that does not expose your magnet to abrasive or corrosive elements, a fabricated magnet may be a reasonable option. Evaluate the materials used in the magnet’s construction and their resistance to wear, tear, and corrosion.

Ease of maintenance is another crucial factor. Evaluate the accessibility of critical components for inspections and repairs. A magnet designed for easy maintenance will reduce downtime, and ensure smooth operations.

Furthermore, consider the availability of spare parts for the magnet. Ensure that the manufacturer or supplier offers readily available spare parts to minimize any potential delays in maintenance or repairs. Type W Magnet leads and cable are among the most commonly replaced items. Be sure your supplier has a steady flow of these items on hand.

By prioritizing durability and maintenance considerations, you can invest in a magnet that will withstand the rigors of your operating environment, reducing downtime and enhancing the overall longevity of your equipment.

#6: Seek Expert Advice

When it comes to investing in a scrap handling magnet, seeking expert advice can prove invaluable. Consult with experienced professionals who specialize in scrap handling magnets. These experts possess in-depth knowledge of the industry, including the latest technologies, industry trends, and best practices. They can provide valuable insights, recommend suitable options, and guide you through the selection process based on their expertise and understanding of industry standards. By consulting with experts, you can gain a broader perspective, consider factors that may have otherwise been overlooked, and make a more informed decision.

An Informed Decision

In conclusion, investing in the right scrap handling magnet requires careful consideration of various factors. By following the step-by-step approach outlined in this guide, you can make an informed decision that aligns with your specific requirements and ensures efficient and reliable performance.

Remember to determine your specific needs, thoroughly research magnet types, assess lifting capacity, consider magnet size and shape, evaluate power source and control, assess durability and maintenance, and seek expert advice.

While comparing prices and warranties is important, evaluating the supplier’s experience, reputation, and customer support is equally crucial. By dedicating time and effort to the selection process, you can invest in a scrap handling magnet that meets your needs, enhances operational efficiency, and contributes to the overall success of your business. | WA

Sean Abenstein has been a Senior Sales and Operations Consultant in the waste industry for more than 20 years. In his role as Chief Commercial Officer for Gensco Equipment, he continues to provide consulting and strategic expertise and has been published in several magazines and articles. His extensive knowledge of the recycling and demolition industry has made him an invaluable resource for thousands of owners, operators, and dealers over the years. Sean can be reached at (416) 465-7521, ext. 202, or e-mail [email protected].