By simply incorporating a wheel maintenance program that includes sanding and polishing, you will improve your inspection process, increase your overall wheel health and boost the reputation of your fleet.

By Chelsey Carrigan

As more and more aluminum wheels are being put into service in the waste industry, it is important to ensure that they are being properly maintained. While just soap and water can remove superficial layers of dirt and debris, this method does not provide any other benefits to overall wheel health.

Adopting a more thorough wheel maintenance program can increase routine inspection effectiveness, improve overall fleet safety and boost the image of your company within your community.

Rim and Wheel Inspection

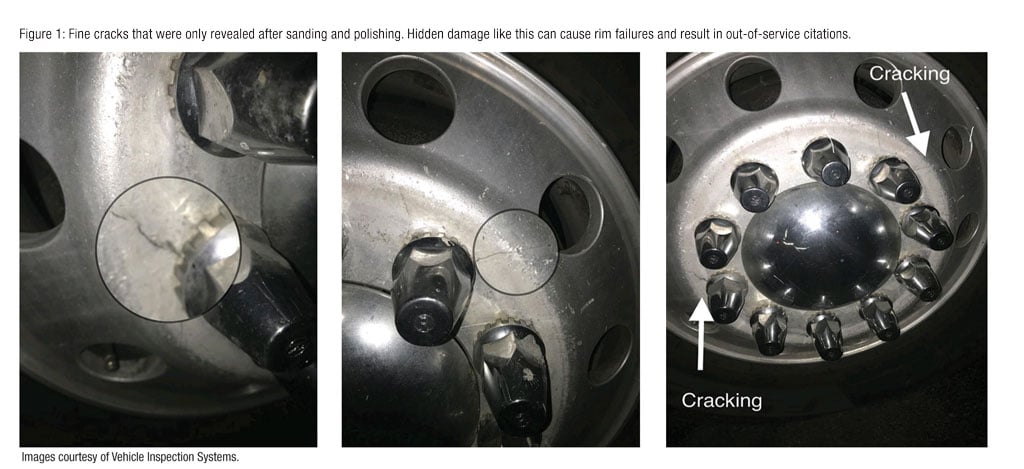

Depending on where your vehicles are traveling, they can collect any matter of dirt and debris during their daily activity. Those layers of build-up can be hiding potentially hazardous damage. Fine cracks, elongated bolt holes, dissimilar metal corrosion, deterioration of the aluminum in the bead seat, and warped or bent rim edges can be difficult or impossible to see during a routine visual inspection. Usually before these inspections are performed, wheels are washed or wiped down, but what happens when that process just is not enough? For example, the wheel pictured (Figure 1) passed its initial visual inspection. However, after completing a full wheel maintenance process that included sanding and polishing, cracks and other damage were revealed.

Improving your aluminum wheel inspection process not only helps avoid rim failures and out-of-service violations, but also contributes to your fleet’s overall safety. According to data trends from FMCSA, the risk of crashes and incidents decreases as the volume of routine inspections increases. This can even contribute to a decrease in a company’s BASIC risk rating.

Wheel Assembly and Rim Surface Integrity

Not only is a fully maintained wheel necessary for proper inspection, but it can also improve the integrity of your rim surface as well as the entire tire and wheel assembly. Things like rust, pitting, and dissimilar metal corrosion can affect the reliability of the rim. By routinely sanding and polishing your wheels, you can help remove these elements before the wheel is compromised.

A maintained wheel surface also ensures that proper clamping force of the lug nuts is retained after servicing. If there are lingering materials like dirt, paint, or rust left between the lug nuts and wheel surface during service, wheels can lose torque and become loose more quickly. The debris can compress or wash away leaving gaps between the lug nuts and the wheel surface, reducing the clamping force and increasing the chance of losing lug nuts or wheels.

Curb Appeal

Well-maintained wheels not only improve safety, but they can also enhance your company’s community image. Pristine wheels give customers the impression of quality and safety. By getting a deeper, longer lasting luster through sanding and polishing, you get wheels that are not just clean, but also stand out. Paying attention to small details like your vehicle’s wheels, shows that your company not only cares about its fleet maintenance, but also its image while in customers’ neighborhoods. Attractive, well-maintained vehicles are perceived to be safer. Not only do customers feel more at ease when they see well maintained vehicles, but drivers and employees will also feel safer while out on their routes.

When drivers climb into a shining and sparkling vehicle at the start of their day, they feel a sense of pride in their vehicle and their company. Building fleet pride with employees can help recruit and retain drivers. Who does not want to drive a well-maintained and clean vehicle day in and day out? Giving drivers a vehicle that they are proud of can lead to better driver retention rates and can also affect employee performance. When you feel pride in your ride, you are more likely to put that effort into your job responsibilities.

Exceptional Services

By simply incorporating a wheel maintenance program that includes sanding and polishing, you will improve your inspection process, increase your overall wheel health and boost the reputation of your fleet. Your company will be one that is recognized for its focus on safety and its dedication to providing exceptional services for the community.

Chelsey Carrigan is the Marketing Manager for Vehicle Inspection Systems (Orlando, FL). She can be reached at (407) 206-3615 or [email protected].

For 25 years, Vehicle Inspection Systems (VIS) has been a front-runner in brake and undercarriage inspection as well as wheel and rim safety for the trucking and transportation industry. VIS brings work place automation and best practices to fleets, service shops, waste companies, enforcement, owner/operators and more. VIS manufactures and distributes a variety of products including the VIS-Polish: Automated Aluminum Wheel Polisher, VIS-Check, Squirrel, and BrakeMate for use with trucks, buses, and other commercial and heavy-duty vehicles. For more information, call (866) 847-8721 or visit www.vischeck.net.