John L. Roll, Ph.D., P.E., and Ed Kallas, P.E.

Treating collected leachate is a significant cost for a landfill and upon closure the liability to treat leachate can continue for 30 to 50 years. Most small landfill operations collect their leachate and truck or pipe it to a local a publically owned treatment works (POTW) for treatment and disposal. This includes a delivery expense per unit volume, and the POTW charges a unit cost per volume to accept the leachate into its wastewater for treatment.

Costs for piping or trucking and unit disposal costs from the POTW are on the rise. In addition, tightening Federal and State regulations on discharge of nutrients (nitrogen and phosphorus) from wastewater treatment operations has resulted in rejection of leachate by smaller local POTW operations. If a local POTW can’t accept the leachate due to water quality concerns, then the landfill operation must pre-treat or find a larger POTW that can and will accept the untreated leachate. Forward-thinking landfill operators are looking for alternatives to treat leachate to a level which lessens the uncertainty associated with acceptance of leachate for disposal.

Wisconsin, Iowa and Minnesota

How leachate is treated and disposed by an individual landfill in the U. S. is dictated by the local or State regulatory requirements. For example, leachate handling in the three neighboring states of Wisconsin, Iowa and Minnesota exhibits how the regulatory requirements can differ. Iowa and Minnesota have a definitive regulatory procedure to permit bio-engineered leachate treatment using a system of constructed wetlands. In these States, treated leachate effluent meeting a target quality standard can be disposed by irrigation on crops or put through a polishing wetland prior to discharge to waters of the state. In Wisconsin, the regulatory requirements for leachate control historically required total capture with wastewater treatment onsite to meet National Pollutant Discharge Elimination System (NPDES) discharge standards, or trucking/piping to a POTW. The Wisconsin Department of Natural Resources (WDNR) will consider bio-treatment wetlands for leachate, but under current regulatory rules it could require permits from three or four different divisions. This means permitting bio-treatment of leachate in Wisconsin is challenging.

Vernon County Landfill

The Vernon County (WI) Landfill is a forward-thinking operation interested in designing a leachate bio-treatment system. This paper discusses collaboration between Applied Ecological Services (AES), a full-service environmental consulting and ecological restoration company based in Wisconsin, with 10 offices nationwide, and Vernon County to design a leachate bio-treatment system with the goal to receive WDNR approval. Treatment options investigated for Vernon County included:

- A package treatment plant to treat leachate prior to trucking to a POTW

- A package treatment plant to treat leachate with a dedicated underground line to the local POTW

- A bio-treatment leachate system.

The bio-treatment system is a viable option. Its construction and lifetime operating costs are lower than a package treatment plant and the certified wastewater plant operator required for a package plant is not required. Bio-treatment has proven at other locations that it can reach an effluent quality suitable for land application on a long-term basis.

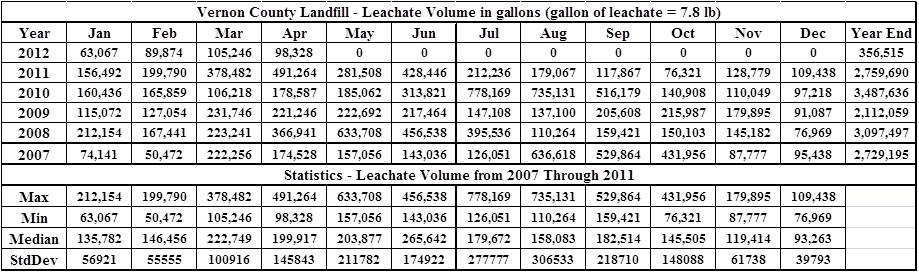

The Vernon County landfill is a bale operation receiving municipal solid waste from the local area. Currently, the leachate is trucked to the local POTW. If the ammonia concentration is too high, then leachate is refused by the local POTW and it is trucked at a significantly higher cost to a larger POTW further away for disposal. Table 1gives a breakdown of the landfill leachate volume sent to a POTW from 2007 through 2011. The volume varied from 2.1 to 3.5 million gallons with the variance related to precipitation. In 2011, the landfill made operational changes decreasing the precipitation runoff flowing into the landfill. The lower volume is a direct saving to the landfill and a less variable yearly volume is a plus when designing a biological treatment system for leachate.

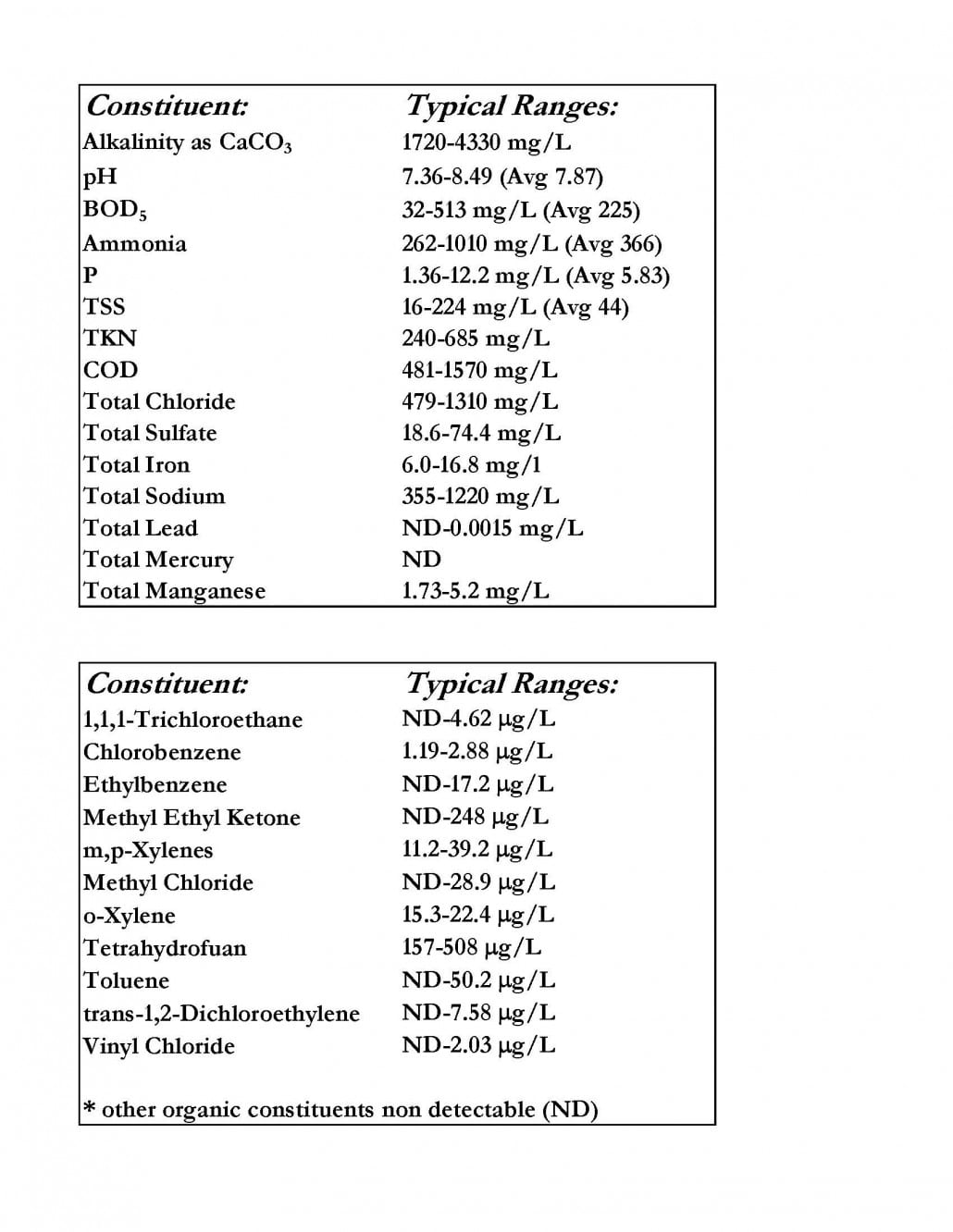

Ammonia concentration is the parameter that determines whether the local treatment plant can accept the leachate and still meet its discharge limits. A bio-treatment system to pre-treat and lower the ammonia concentration is a cost-effective option for Vernon County. It is an ecologically friendly alternative with the potential to irrigate nearby fields with the treated leachate, eliminating the cost of trucking the leachate to a POTW during operation and closure. Table 2 lists leachate water quality parameters for Vernon County.

Incorporating Bio-Treatment of Leachate

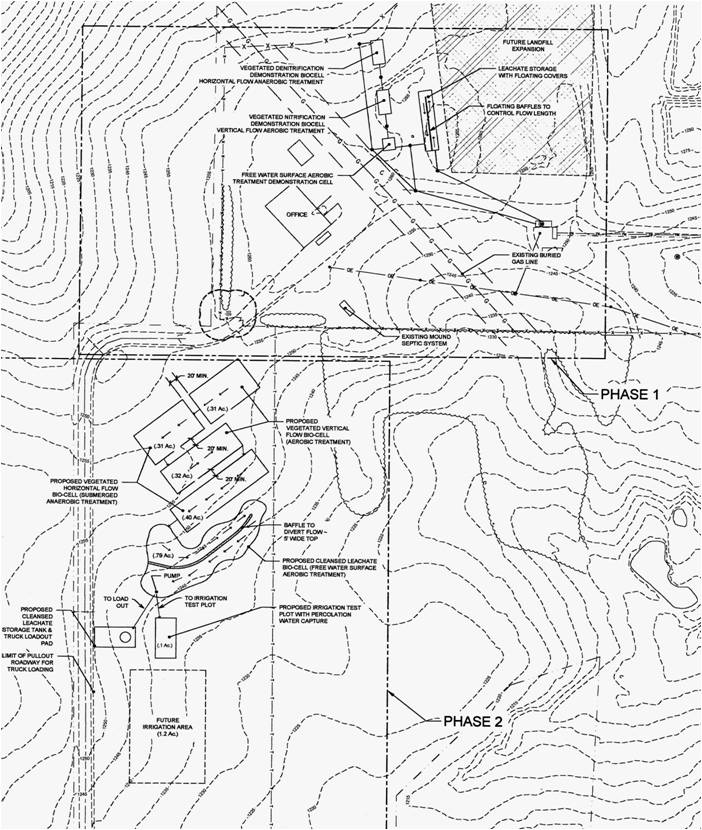

The landfill and AES reviewed their plans to determine how to incorporate bio-treatment of leachate for their operation. These discussions led to the proposed design shown in Figure 1. AES developed a phasing concept similar to that shown in Figure 1 to construct a bio-treatment system that would accommodate current and future landfill activity. The concept was to excavate a holding basin in Phase 1 to meet the landfill’s immediate need for additional external storage of leachate that would lower the water level in the landfill. Reducing the time that leachate is exposed to landfill waste is expected to improve water quality and, more importantly, improve the treatability of the leachate. Leachate would be transported to the POTW until the second phase is completed, so total containment is maintained with Phase 1. The basin volume in Phase 1 would hold the leachate produced during four months (approximately one million gallons).

Phase 2 would be constructed in conjunction with clay borrow activity intended to cover the completed landfill area in three to five years. To meet WDNR requirements, all bio-treatment basins accepting raw or partially treated leachate would be constructed with total containment using a 60-mil liner underlain by two feet of compacted soil to be approved by WDNR. The Phase 2 bio-treatment of the leachate would reduce ammonia levels by a combination of nitrification and denitrification. This would allow trucking to the local POTW with less concern over a load being rejected by the treatment plant. The concept was discussed with WDNR in meetings and it was clear from these discussions that acquiring a permit to build the second phase would be difficult. The plans for Phase 1 were revised to construct the basin with demonstration nitrification and denitrification wetlands to show the WDNR the potential of bio-treatment. Phase 1 can be permitted on a demonstration variance within current regulations.

The basin and demonstration cells in Phase 1 will be constructed with a 60 mil liner over compacted clay. The leachate holding basin will have floating baffle screens to create a longer flow length without losing volume to earthen baffles. The basin will be covered with a floating cover to eliminate precipitation mixing with the leachate and to control potential odor from the untreated leachate. Aeration of the leachate in the basin is under consideration. The demonstration cells are adjacent to the holding basin and will use a vegetated vertical flow nitrification (aerobic) cell and a vegetated horizontal flow denitrification (anaerobic) cell as the primary removal mechanism for nitrogen. To determine performance of the demonstration cells, water quality sampling will be done at the inlet and outlet of the holding basin and at the outlet from the nitrification and denitrification cells. The system is designed for all leachate from the holding basin and the demonstration cells to be collected and trucked to the local POTW, as before.

The leachate inflow and detention time in the demonstration basins can be varied to determine the best combination to provide treatment. This data can be used to demonstrate bio-treatment potential to WDNR prior to applying for a permit to construct Phase 2. To determine the exact sizing and design of the Phase 2 cells, AES will use the water quality performance data collected from the demonstration cells. AES, Vernon County and the WDNR hope the bio-treatment data collected from Phase 1 will provide the first-hand experience the agency would need to revise its permitting process for the complete system shown in Phase 2.

A Cost-Saving Alternative

Bio-treatment processes can be designed to treat and remove nitrogen, BOD/COD, salts and metals. When it comes to landfill leachate, onsite bio-engineering treatment cells are viable, cost-saving alternatives to mechanical and offsite treatment. Not only do these solutions reduce operation and maintenance costs, but they also provide enhanced aesthetic appeal and community relations by adding green space and wildlife elements to the landfill.

John L. Roll, Ph.D., P.E. is Senior Environmental Engineer for Applied Ecological Services, Inc. (Brodhead, WI). He can be reached at [email protected].

Ed Kallas, P.E. is Staff Engineer for Applied Ecological Services, Inc. He can be reached at [email protected].

References

- Kadlec, R.H. and Wallace, S.D. (2009). Treatment Wetlands, Second Edition. CRC Press. Boca Raton, FL.

- Atlus, R.M. and Bartha, R. (1998). Microbial Ecology, Fundamentals and Application, Fourth Edition. Benjamin/Cummings Publishing. Menlo Park, CA.

- Wallace, S.D. and Knight, R.L. (2006). Small-Scale Constructed Wetland Treatment Systems, Feasibility, Design Criteria, and O&M Requirements. Water Environment Research Foundation. Manual 01-CTS-5. Alexandria, VA.

- Vernon County Landfill. (2010-11). Correspondence and discussions with landfill manager and County Board Landfill Committee.

- Wisconsin Department of Natural Resources (WDNR). (2010-11). Correspondence and discussion with regulatory staff.

Table 1

Vernon County Leachate Volume.

Table 2

Vernon County Leachate Water Quality.

Figure 1

Plan View of Proposed Leachate Bio-Treatment for Vernon County

Tables and Figures courtesy of Applied Ecological Services.