Ripple effects of manufacturing and supply strains have been making their way into the heavy-duty truck parts and service suppliers’ market, potentially increasing wait times for repairs and maintenance work. It’s left to parts counter managers, fleets and others to navigate and outmaneuver difficult pricing and supply waters.

Part of the problem stems from the more intense months of the pandemic, particularly in mid-to-late 2020. Outbreaks of coronavirus and preventive measures to help stem the disease caused shutdowns and suspensions in manufacturing plants of all kinds, eventually creating hiccups and blips in supply across many markets — certainly not just trucking. As demand remained steady or even spiked for certain items, it meant slowdowns in availability of product.

Then there’s the infamous, global and continuing semiconductor shortage. This, too, has roots in the COVID-19 pandemic, which helped boost demand for, and purchases of, smartphones, laptops and other connectivity devices, since in-person contact was limited. And meanwhile, production had slowed or shut down for vehicles, from Class 1 passenger cars to Class 8 heavy-duty trucks.

With production back up and running, there suddenly weren’t enough semiconductor chips to go around, and it has stunted the assembly of today’s highly computerized vehicles. Vehicle makers of all kinds have been challenged to get enough parts to complete their products, with one recent example being Hyundai, which had to suspend its Montgomery, Ala. auto production line for a week in mid-June due to the chip shortage, the Montgomery Advertiser reported.

Back in March, Volvo Group announced that the semiconductor shortage would have a “substantial” impact on its global truck manufacturing operations, saying the company would implement “stop days” at plants that would amount to two to four weeks, depending on the production facility. “Visibility into the global supply chain of semiconductors as well as other components is currently very low, and the uncertainty about the development is high,” the company said in a statement.

“The disturbances are expected to have a negative impact on earnings and cash flow,” it continued. “The Volvo Group and its business partners are working hard to minimize the number of vehicles affected and the impact on customers by keeping flexibility to be able to increase production when possible.”

Another material that has been in short supply is natural rubber. There has been a series of elements affecting the natural rubber supply, Bloomberg reported back in April, including a leaf disease that spread across rubber trees. And China also bought up rubber supplies in late 2020, taking advantage of low market prices at the time to add to its national reserves. Earlier this year, the Ever Given container ship’s blockage of the Suez Canal for six days also slowed rubber shipments, among others, which helped disrupt production of parts that utilize the material.

In the trucking industry, all this has amounted to slowdowns and manufacturing delays of everything from the trucks themselves to various parts used to construct or maintain them. It has gone as far as to affect earnings and output of OEMs, dealers and parts/service providers such as Rush Enterprises, the nation’s largest truck dealer network and an “all makes” parts supplier and servicer.

W.M. “Rusty” Rush, the company’s chairman of the board, CEO and president, said during a first-quarter earnings call that the parts and materials shortages are “flattening” parts and service earnings slightly, but added that Rush Enterprises expects the shortages to taper off by the end of the third quarter this year. The company is tapping its nationwide inventory to help source out any parts that are unavailable or delayed, but the shortages have also been difficult to predict.

“When you talk about things [in short supply] outside of semiconductors, it’s just a myriad of things,” Rush said. “One day it could be wiring harnesses, one day it could be dash clusters or seats. I think it’s just across the board with your Tier 2 and Tier 3 suppliers. The manufacturers are managing as best they can, but I think they keep getting hit with different issues from different suppliers.”

He noted that several parts suppliers seem to be having production difficulties after COVID shutdowns. “It’s even just keeping up with it — ramping up after COVID has been very difficult for Tier 2 and Tier 3 suppliers, and not just on the semiconductor piece,” Rush said. “From a parts perspective, if you look at our parts inventories, we’ve got more parts backordered right now. That’s one of the issues you run into. It trickles not just through trucks; it actually trickles through parts and service, too.”

“You never know how it’s going to affect you from day to day or week to week or month to month,” he emphasized. “But I do expect [the shortages] to get cleared out.”

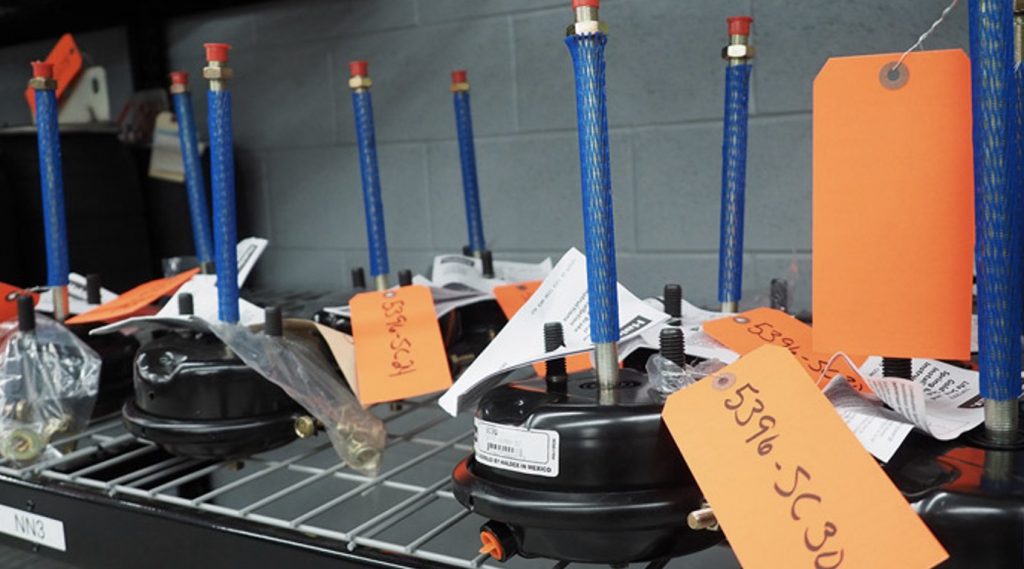

One solution to the problem is also helping perpetuate the problem: stockpiling. As materials and parts have been harder to source reliably and when needed, manufacturers, parts suppliers and even fleets are trying to build up stocks of items or materials when they are available — potentially squeezing supplies for others down the road.

“Some of these larger groups that have some money are accelerating their parts purchases,” said Paul Moszak, vice president and heavy-duty evangelist at MOTOR Information Systems. “They’re taking a three-year budget and consolidating it into one year, for example. Say they spend $1 million each year to buy parts; they’re getting loans for $3 million this year to order those parts right now — all of them — for the next three years.”

“It’s going to contribute further to the parts shortage,” he explained, “because they’re going to get priority since they’re heavy buyers in the first place. So, all these manufacturers are going to be struggling to meet their demand, and these [future purchasing buyouts] will lessen availability in the industry.”

MOTOR offers a product called FleetCross that may provide some relief. The product includes more than 45 million cross-references for medium- and heavy-duty parts, from OEM to aftermarket, identifying parts with similar fit and function.

“MOTOR’s solution for Fleets enables our clients to quickly identify alternative part numbers preventing work stoppage in lieu of the increasing supply chain part shortage. For Part Suppliers, our professional services provide the tools to cross-reference the alternative part numbers back to their sellable parts so they can utilize their existing parts inventories. The end result is helping Fleets maintain up-time while helping the Part Suppliers continue to sell parts!” said Thomas Noack, director of sales for heavy-duty at MOTOR Information Systems.

Darry Stuart, owner of DWS Fleet Management Services, said he has heard from several fleets that have run into parts availability issues. For instance, there have been some shortages with tires, a national backorder of NOx sensors, and “quite a few smaller parts that go into the truck,” he noted. But Stuart cautioned that some parts shortages could even be fabricated, essentially so that parts retailers can get higher margins on their inventory.

He had some advice to help. “Let’s say a fleet calls up the dealer and the dealer says, ‘We don’t have the part, but I’ll order it for you.’ I’ve told the fleets, don’t stop just because you make one phone call. I want you to hit the button on the phone until your fingers fall off,” Stuart said. “Keep calling everywhere until you find it — somebody has that part on the shelf. Yes, you may have to pay the freight to ship it in, but it’s out there.”

“The fleets that aren’t aggressive, they have more of a parts shortage,” he added. “But for the ones that are aggressive and don’t give up, the parts shortage hasn’t really affected them as much. If the fleet does not give up hunting for the part, there’s a better chance that any price increases in the cost of those parts will stay reasonable.”