Partnership creates cost-effective, environmentally sound landfill solution.

By Trevor Mahoney

Harmac Pacific knew they were on the verge of a significant problem. In the spring of 2019, the airspace at its landfill would run out and, without finding an innovative way to create more capacity, an economically-viable waste disposal solution would be very tough to come by.

The Harmac Pulp Mill Landfill is owned and operated by Harmac Pacific (Harmac), a division of Nanaimo Forest Products. The company’s facility, located just outside of Nanaimo, British Columbia, includes a pulp mill, the industrial landfill and operational infrastructure. The landfill accepts the solid waste produced by the pulp processes.

In the summer of 2016, the company made the decision to start the process of expanding the landfill at its current location. Harmac needed a landfill expansion that would allow for the safe and responsible disposal of waste for the next 15 to 20 years. Unlike a municipal solid waste landfill, Harmac does not receive a fee per ton for waste placed in its landfill. The company does not make money from its landfill activities either, so economics, as well as the environment, were the main drivers. The company does not make money from its landfill activities; instead, all funding for capital projects and the operations of the landfill come directly from the profits of the pulp mill. As a result, they wanted a consultant who could provide a design that maximized the capacity and lifespan of the expansion while keeping the capital costs to a minimum.

“We chose XCG based on their experience on similar projects and their ability to work closely with our project team to develop different design concepts,” said Ryan Prontack, Engineering Superintendent, Harmac Pacific.

XCG Consulting Limited is Canadian-owned and capable of delivering a range of specialized services in a variety of environmental areas. Founded in 1990, XCG offers a full range of solid waste management services to public and private clients. XCG’s services for solid waste management include landfills, transfer stations, composting facilities, and emerging technologies, working with clients to ensure that solid waste management facilities are properly designed and well managed so that the facilities are a valuable resource, rather than an environmental liability.

Images courtesy of Trevor Mahoney, XCG.

While XCG reviewed the permit for the site and began the initial design steps, Harmac began the preparation of the site by stripping the overburden soils from the expansion site and exposing the bedrock. Once the bedrock was exposed it highlighted a major design challenge for the project, generally high bedrock elevations and several outcrops in the middle of the expansion area. The companies worked through several design options that optimized the landfill capacity and limited the amount of bedrock blasting. The decision was made to work leachate-collection pipes around the majority of the bedrock outcrops and limit the bedrock blasting to the perimeter road around the outside of the expansion.

Design Brief

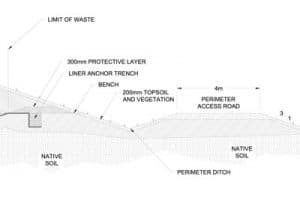

In the spring of 2017, XCG submitted a design brief to the B.C. Ministry of Environment and Climate Change on behalf of Harmac for approval. The design brief contained the plan for the expansion of the landfill and was based on standard engineering practices and limitations outlined in permit PR02205, dated July 23, 1995. The design of the landfill expansion included a five-meter-wide perimeter road, open “v” ditches to convey surface water, three vertical to one horizontal side slopes, and an engineered landfill liner.

The engineered liner for the site consists of a 100-millimeter thick sand layer placed directly on top of the bedrock to provide a cushion layer for the synthetic components of the liner. On top of the sand, a 1.5-millimeter high-density polyethylene (HDPE) liner was placed creating an impervious barrier preventing leachate infiltration to the groundwater. Above the HDPE line was a 300-millimeter thick gravel drainage layer with perforated leachate collection pipes that directed leachate to the low point in the design where a gravity main conveyed the leachate to the sites water treatment facility.

Detailed Design

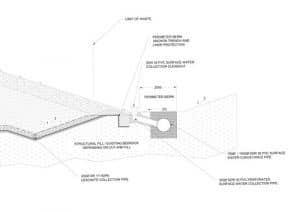

Once the general design was approved by B.C. Ministry of Environment and Climate Change, the two companies worked in tandem, sending drawings back and forth in an effort to refine the design and increase the capacity of the landfill. The decision was made to remove the perimeter road and instead narrow it to a perimeter berm. By eliminating five meters of width from the perimeter structure, the site capacity increased and the amount of construction materials required, as well as the amount of bedrock removal required during construction, were reduced. “It was an iterative process, and when compared to our initial ideas, the final design achieved approximately 40 percent additional landfill capacity for the same capital invested,” said Prontack.

Sharing ideas throughout the design process paid off. Harmac has a wealth of experience with pipes and flows through their mechanical processes at the plant. Using that expertise, XCG was able to work pipes into the design and eliminate the open surface water ditches. This represents another simple design change that had a significant impact on the capacity of the site as well as the constructability of the project.

“The project presented a unique challenge for our company. We know landfill design, but working leachate collection lines around bedrock outcrops and surface water pipes instead of open ditches required new approaches to issues we typically come across on landfill design projects,” said Tom Williams, President, XCG Consulting Ltd.

Final Product

Construction of the landfill expansion began in the winter of 2017 and was completed in September 2018. The completed landfill expansion will allow for the disposal of more than 1,200,000 cubic meters of solid waste produced by the pulp processes—approximately 25 years of airspace. Throughout the design and construction process, XCG worked closely with Harmac to produce a design that meets the needs of the site and maintains a low construction cost.

Trevor Mahoney is a project specialist with XCG Consulting Ltd. and lead designer on the Harmac Pulp Mill Landfill Expansion project. Trevor has more than 15 years of experience in landfill design and construction quality assurance, including materials testing for construction of environmental control systems at landfills. He has completed detailed designs, design and operations plans, performed construction quality assurance, and contract management for various landfills throughout Canada and the U.S. These landfill designs have included composite liners, leachate collection systems, composite final covers, landfill gas collection and use, and leachate recirculation. Trevor can be reached at (519) 741-5774, ext. 7237 or via e-mail at [email protected].