Examining the ROI of a smart fleet management system.

By Tom Gill and Don Diego Padilla

According to a recent study by Grand View Research, Inc., the global smart fleet management market is projected to top U.S. $565 billion by 2025. The estimated annual growth rates of nearly 10 percent will be driven by a burgeoning demand for mobile connectivity to deliver safer, cheaper and greener services. The smart waste management market is predicted to grow at an even higher rate of nearly 20 percent annually. The expanding availability of smart truck technologies and associated benefits—including improvements in operations, sustainability and safety—will continue to drive this market growth. Strengthening government safety regulations are also expected to intensify demand for smarter fleets.

Smart Waste Fleet Management System Components

A smart fleet system typically provides capabilities for vehicle tracking and monitoring, fleet analytics, fuel management, predictive maintenance, remote diagnostics, driver performance monitoring and more, to increase operational efficiency, enhance productivity and safety, and ensure widespread cost savings.

These savings are predicated on onboard computing (OBC) and camera solutions that capture and store imagery, electronic control module (ECM), and other vehicular data to provide accurate performance reporting and real-time alerts. These systems provide unprecedented real-time information to drivers and dispatchers about a truck’s load-weight, route status, service completion, vehicular telemetry, driver activities and more, and further manage a wide range of inputs from a vehicle’s onboard systems (such as cameras, scales, RFID readers, tire pressure and fuel monitoring). The result is a truck with a 360-degree view into all of its activities.

Quantifying the Savings

While most fleet managers understand that there are savings and efficiencies from smart fleet technology, they are often hard to quantify. Figure 1 details expected ROI scenarios spanning driver activities, vehicle maintenance and fuel savings as derived from a municipal deployment scenario that includes 42 trucks, 35 routes and 73,000 residential customers.

Driver Hours/Overtime Savings: Average of $3,643 Per Driver/Per Year

By reducing driver hours and overtime costs, the municipality can save an average of $3,643 per truck annually. These savings are derived as a result of the following:

• Optimized dispatch/routing

• Less outbound planning

• More efficient communications

• Reduced driving time

• Automated run sheets

• Less administration time

Vehicle and Maintenance Savings: Average of $2,112 Per Truck/Per Year

By better monitoring and tracking driving behavior and proactively maintaining vehicles, the municipality can save an average of $2,112 per truck/per year. These savings are derived as a result of the following:

• Managing braking

• Monitoring driving patterns

• Safer driving/less accidents

• Less idling

• Less maintenance

Smart fleet technology also delivers real-time business intelligence on your performance so you can identify problems in hours rather than days. This enables you to be proactive to act and resolve issues faster. Time is money—and a problem fixed quickly is a far less costly problem.

Fuel Savings: Average of $1,408 Per Truck/Per Year

By optimizing routes and ensuring more emissions-friendly driving, the municipality can save an average of $1,408 per truck/per year. These savings come from:

• Reducing idling

• Managing speeding

• Minimizing unnecessary travel

For this municipality, the overall average savings per truck/driver annually total $7,163—an annual bottom-line benefit of more than $300,000. While ROI results will fluctuate based on a number of fleet variables and the types of technology solutions used, it is clear that smart fleets will significantly impact the bottom line.

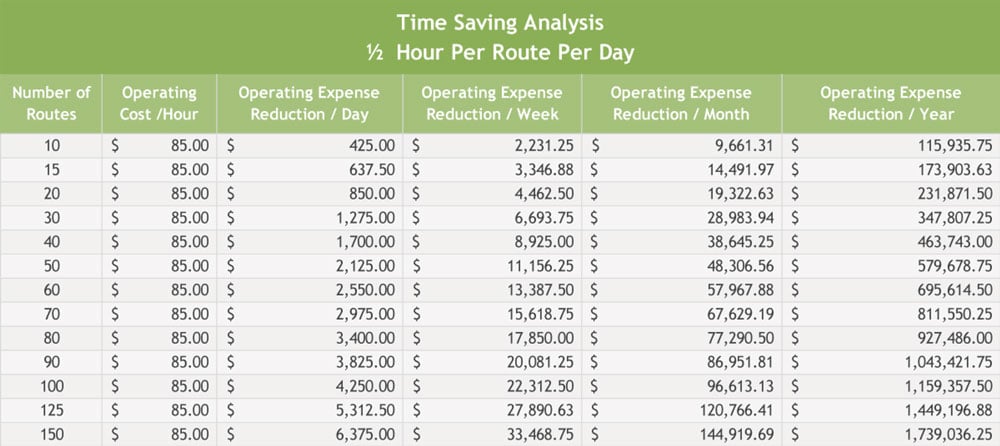

Time Savings View: 30 Minutes Per Route Per Day

Smart fleets are fleets that manage their daily routing activities to achieve maximum efficiencies. Real-time fleet tracking and turn-by-turn driver directions take the guesswork out of managing routes and ensure planned route adherence to minimize the distance, amount of fuel used, and amount of time required to complete assignments. Deployment of a smart fleet system with route management features can be expected to help save up to 30 minutes per route, per day. This works out to an annual cost savings benefit of more than $11,000 per route. Let’s break this down to a 10-route scenario that operates at a cost of $85 per hour. By reducing the routes by 30 minutes, you would save $425 per day, $9,661 per month and nearly $116,000 a year. A compelling ROI!

Additional ROI Factors

The ROI potential of a smart fleet is clear. But there are additional tangible and intangible improvements that also need to be considered.

RFID and Asset Tracking

Radio-frequency identification (RFID) uses electromagnetic fields to automatically identify and track tags attached to objects. RFID is widely used to automate garbage collection whereby tags are read with RFID readers by drivers in waste trucks. Keeping track of bins manually is time consuming and prone to human error. Bins with RFID tags allow waste management organizations to operate more efficiently by better managing individual carts and customers. RFID tags also make it possible to implement and operate loyalty and recycling reward programs. From an ROI perspective, RFID tagging and tracking vastly improves the manageability and maintenance of refuse containers, which in turn improves overall fleet productivity.

Unsafe Equals Expensive

As urban centers grow and become more dense, ensuring safety during waste collection becomes more complicated. Every year, according to the National Safety Council, an estimated 20 percent of all fleet vehicles are involved in accidents, which has both profound human and bottom-line impacts.

Let’s address the human impact first. Reducing—if not eliminating—injuries and fatalities is every fleet operator’s goal. Whether a pedestrian or sanitation worker, any life saved or injury prevented is an immeasurably positive outcome. Most accidents are avoidable, and effective waste fleet safety management can reduce the risks significantly. A smarter, safer fleet can potentially cut the frequency of accidents in half by integrating advanced technologies to collect and communicate important data regarding routes, drivers, civilians, obstacles and vehicle systems. For example, Andrew Page, which operates a 900-vehicle transport fleet in the UK, realized a 97 percent reduction in speeding and a 47 percent reduction in crashes and other incidents by deploying a smart fleet telematics solution.

The bottom-line impact of accidents is also immense. It is extremely expensive to be unsafe when you consider liability, insurance, downtime, repairs, legal costs and much more. The ROI of a smarter, safer fleet can be measured in two key ways. The first is by reducing your overall rate of accident incidents through safer driving and improved visibility. The second is to reduce the cost of accidents when they occur (and they will) by capturing real-time and accurate data to better manage and respond to incidents.

Smart fleets now come with integrated safety dashboards—Web portals that provide live video feed, archived video and picture views into fleet, driver and collection services activity. Waste fleet managers benefit from an intuitive back-office view into what is going on for each route, truck and driver, taking advantage of digital video recording (DVR) functionalities. They can spot costly and unsafe driver maneuvers, know how vehicles are being handled, plot location of alarm occurrences, determine which drivers generated alarms and where, replay selected vehicle and driver activities. With this greater insight, communities are better equipped to mitigate unnecessary risks and better manage emergency situations.

The North Carolina Department of Transportation (NCDOT) reduced injury claims by 75 percent as a result of video surveillance systems around its vehicles. National Transportation Safety Board (NTSB) research indicates an estimated 20 to 35 percent reduction in crashes as a result of vehicle camera systems. The Federal Motor Carrier Safety Administration (FMCSA) conducted field operational tests of driver behavior monitoring using event-based video systems that resulted in a significant reduction in safety-related incidents. Smarter trucks are safer trucks, and the ROI of being safer simply requires no justification.

All in the Numbers

It is all in the numbers—smart fleets are safer, more profitable fleets. At the end of the day, it simply costs you far more not to have a smart fleet management system. The potential ROI quickly validates the costs. Smart fleets are simply the smartest way to go.

Tom Gill is Safe Fleet’s (Belton, MO) Senior Vice President for Passenger Transportation, Law Enforcement, and Waste and Technology. He was previously the President of Seon, a leading provider of mobile video surveillance and fleet management solutions for buses. He joined Seon as COO in 2009 after serving as President of Signalink, a fire protection, security and medical alert devices manufacturer. Tom is a veteran of the video surveillance industry serving as COO and CFO of Silent Witness prior to their acquisition by Honeywell in 2003, and continuing on as VP, Global Marketing post-merger. He can be reached at [email protected].

Don Diego Padilla is FleetMind’s (Montreal, QC) Vice President of Sales. A waste industry fleet management veteran, Don Diego spearheads business and customer development activities. Previously, he was a Regional Sales Director for Allied Waste, now a part of Republic Services, a leading provider of solid waste collection, transfer, recycling and disposal services in the U.S. Don Diego is a primary contributor to FleetSMARTS, an industry newsletter targeted at fleet organization executives, and a frequent speaker at waste industry forums on smart fleet themes. He can be reached at [email protected].