Nicholas Smith-Sebasto, Ph.D.

In the November 2023 issue of Waste Advantage Magazine, Scott Woods’ article, “Innovations in Composting Biotechnology: Reducing Footprint and Increasing Efficiency”, explored the issue of how “composting operations might simultaneously enhance sustainability and meet the evolving needs of our communities and the planet.” He specifically addressed space, odor control, and processing capacity concerning three specific forms of composting; namely, covered aerated static pile systems, aerated static pile with reversing air and biofilters, and in-building or tunnel systems with biofilters. An important composting biotechnology that he did not address is aerobic in-vessel rotary drum (AIVRD) composting systems, possibly because he addressed conventional composting while AIVRD composting systems are most commonly used when food and other organics are the materials being composted.

Increasing attention is being given to removing food and organics from landfills due to concerns about potential greenhouse gas emissions, of which food is often cited as one of the main causes, as well as surface and groundwater contamination by leachate. Additionally, attraction of undesirable wildlife is often associated with conventional food composting operations. Still, as a poster that once hung in the halls of the Capital of the United States of America proclaimed, “composting is one of the most Earth friendly things you can do.” Several states and municipalities have enacted legislation that bans the disposal of food into landfills. Legislation is pending in several others and similar bills have even been introduced into the U.S. Congress.

AIVRD composting systems typically are plug-and-play systems, which means that once they are powered, they are fully operational and need only a scale to weigh the food and organics to be composted as well as the bulking agent/carbon source and a receiving vessel for the off-loaded compost. They are best applied with onsite or local composting, which reduce or eliminate transportation costs and environmental concerns and provide for the use of compost onsite or locally.

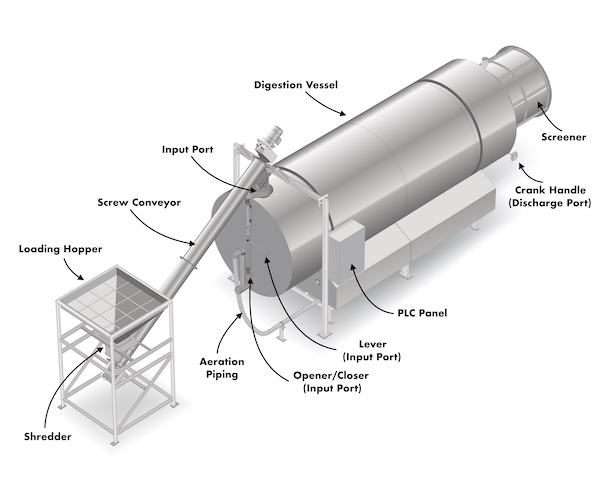

The best AIVRD composting systems include a loading hopper, a volume-reducing shredder, a fully enclosed screw conveyor, a digestion vessel with an attached screener, and a PLC panel with an HMI touch screen. They include operational modes for loading, digesting, and off-loading and are commonly designed for through-put loading; however, batch loading is also an option. AIVRD composting can process both pre-consumer and post-consumer food and organics including raw and cooked meats; fruits and vegetables, including their peels and rinds; dairy, etc. The volume-reducing shredder often reduces the material to be composted to roughly the size of a standard sugar cube. This increases the surface area for the microbial digestion of the material considerably; therefore, the composting process starts more quickly and progresses more rapidly in AIVRD composting systems.

The advantages of aerobic in-vessel rotary drum composting biotechnology, include:

- Space Efficiency: AIVRD composting systems require an amazingly small footprint relative to their processing capacity. For example, an AIVRD composting system capable of processing 260 tons of food and organics annually, will require an operational footprint of as little as 1,000 ft 2. The structure that houses the composting system may be as ornate or basic as desired ranging from a state-of-the-art greenhouse to a fabric quonset hut to a pole barn.

- Odor Control: Because AIVRD are typically fully enclosed systems with programmed aeration and digestion vessel rotation, odors are typically minimal and easily controlled by adequate ventilation of the exhaust air. The aeration is often programmed to occur as frequently as every 15 minutes and provides a full volumetric exchange of air in the digestion vessel to ensure that anaerobic conditions do not occur.

- Reduced Greenhouse Gas Emissions: Because the environmental conditions (O2 levels, C:N ratio, moisture percentage) for the microbial decomposition of the feedstock are optimized, the food and organics are efficiently digested with no anthropogenic greenhouse gas emissions when operated as designed.

- Efficient Processing Capacity: AIVRD composting systems are designed to process food and organic matter in an accelerated manner similar to how a microwave oven cooks food more rapidly than a traditional stovetop or oven. Composting processes that often take months or years in traditional composting operations are reduced to days or weeks with AIVRD biotechnology. Additionally, AIVRD composting systems may be loaded by through-put or by batch loading and, therefore, may be installed individually or in series with multiple systems.

- Versatility: AIVRD composting systems are easily customizable to meet a generator’s needs. The power of the motors, the size of the shredder and/or screw conveyor, the size of the digestion vessel, etc. are all specific to the processing needs. Some AIVRD composting systems have processing capacities that range from 60 tons to 560 tons annually.

Composting is a sustainable materials management option in which bigger is not always better. In fact, the Institute for Local Self Reliance found that “…what is needed is a highly decentralized and diverse organics recovery infrastructure…Communities embracing such an infrastructure will be more resilient and will better reap the economic and environmental benefits that organics recovery has to offer. The potential for job creation would increase if a diverse composting infrastructure was developed that includes many small- and medium-sized operations.”