As an R2 certified electronics recycling company and the first women-owned recycling business in Houston, CompuCycle has led the way in data destruction, e-recycling and refurbishing for more than 20 years.

For more than 22 years, CompuCycle has led the way in the electronics recycling industry. Founded in 1995 by Clive Hess, Executive Vice President, and his father, John, they both immigrated from South Africa and started the company as purely an electronic scrap recycling company, recycling e-products for ferrous, non-ferrous and precious metals. John was in the scrap metal recycling business in South Africa and just prior to immigrating, had started processing e-scrap and precious metal recovery. When Clive and his father immigrated to the U.S., Clive earned his degree in business then joined the company on a permanent basis. Today, CompuCycle has evolved into not only electronic recycling, processing and refurbishing, but the company also provides end-of-life IT asset disposal services to corporations. Based out of Houston, TX, the company operates two facilities, an 80,000 square foot refurbishing facility and a 40,000 square foot processing facility, has 75 employees and collects electronics from around the city on a daily basis.

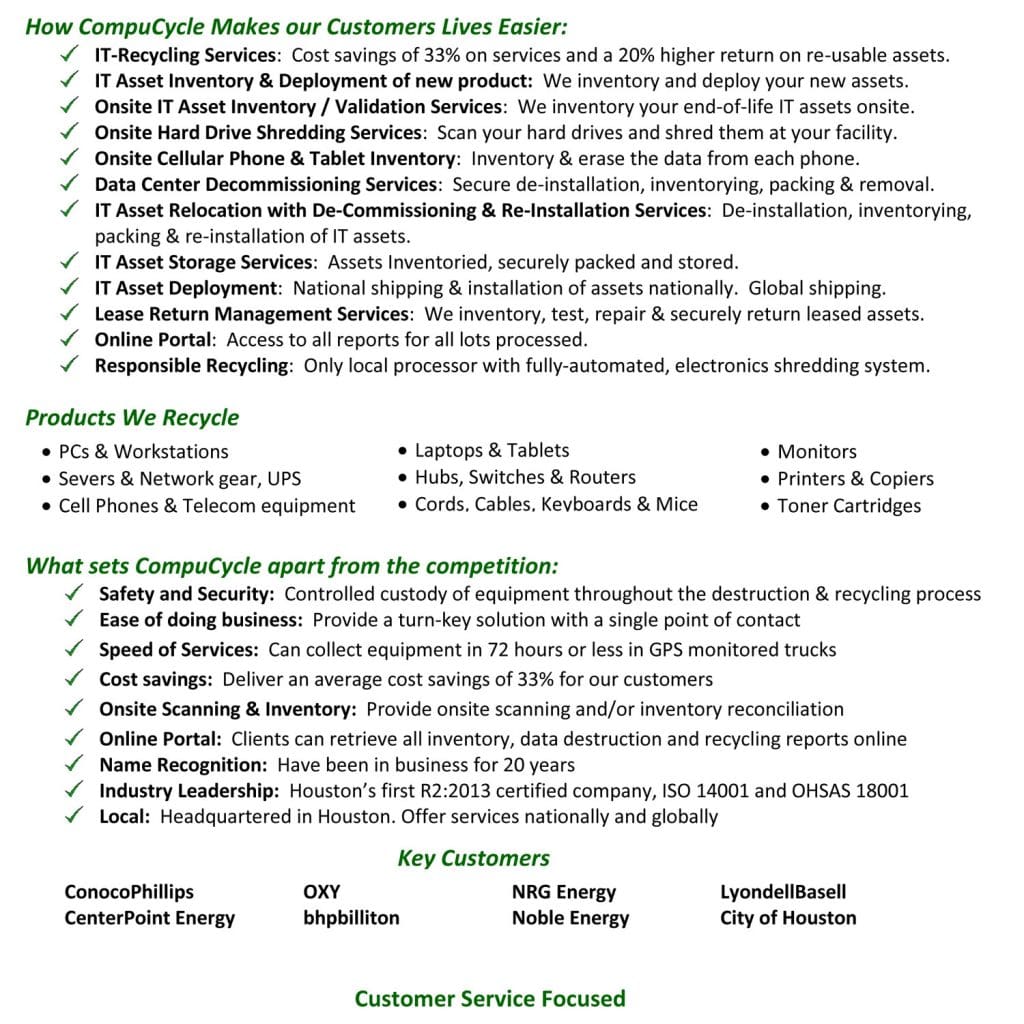

“When it comes to electronic recycling/secure data destruction, that has definitely been our core businesses and services for the last 22 years,” says Kelly Hess, President and CEO of CompuCycle. “We have also focused on services such as decommissioning and IT relocation—when companies move from one place to another, we perform de-installation and take what they do not want to recycle and then reinstall what they would like to keep at their new location. We are able to save time and make the life easier of the individual as well as show a cost-savings and give value back. When it comes to reusables, our goal is first to refurbish and use any of the products we receive and then responsibly and securely recycle components that cannot be reused.”

As an R2 certified electronics recycling company and the first women-owned recycling business in Houston, CompuCycle also meet the needs of their customers nationally and globally. In the U.S., CompuCycle customers have the option of shipping the material to CompuCycle’s facilities or CompuCycle will arrange onsite packing of equipment and secure shipment to its refurbishing or processing facility—programs are tailored to meet customers’ needs. On a global basis, the company works with partners to collect and process the materials in their respective areas.

Moving Forward Amid Change

According to Clive, because of China’s National Sword Ruling, the entire South Pacific region is no longer accepting e-scrap for recycling. As a direct result, there is an immediate need for products to be processed in the U.S. He explains, “Last year we acquired our 40,000 square foot facility and installed a fully automated state-of-the-art shredding system, so now we are able to shred electronics into raw materials—steel, aluminum, copper, plastics and circuit boards. Our sorting system has eddy current optical sorters, which sort the plastic and other materials from the stream. We are now essentially processing the materials into raw materials and those, in turn, are sent to refineries to be made into other goods. Our facility is the only one in Houston, TX that has the ability to shred and separate the e-scrap into raw materials. While we are all affected by what has happened in the industry, how we deal with the commodity changes or the inability to ship products to certain regions is the difference and this is where we have the advantage.” He goes on to say that in the e-world, it used to be a business where there was value in everything and everybody paid for it. However, fast forward to today, and that is no longer the case. “Some materials we charge to process because there is a cost for us to dispose of the equipment. For example, if you look at the plastics industry, there is a tie in with oil prices and the industry is also struggling with the different tariffs—as the metal prices are impacted, we are impacted. We have a price matrix that we send to our suppliers that shows them where prices have increased or decreased, so we adjust our prices as the market adjusts and, at the moment, it is very volatile,” says Clive.

CompuCycle is ISO:14001 certified, OHSAS 18001, R2:2013 and is in the process of becoming ISO:9001 certified. Forty thousand pounds of material per day is processed in one shift. All of the equipment received is processed in a hierarchy—first, if the material can be reused, the assets are tested, and the data is destroyed using DOD compliance software. In the event that the data fails the test process, the hard drives are physically shredded, which guarantees destruction. In addition, for the products that are suitable for refurbishments, CompuCycle tests and cleans the equipment by removing all of the identification labels, and then putting their own label on the parts. “We are a Microsoft registered refurbisher, so can reload software onto the equipment and we sell the equipment to different verticals with a warranty from 30 days to five years. Within that five-year period, if anything fails, we can repair the equipment,” says Clive.

Kelly adds, “We are eliminating any further material downstream by processing these products—we do it all. That is very unique because 98 percent of electronics recyclers in the U.S. do not have the ability to process scrap materials; there is only a handful of companies that can do it and we are proud to be one of them.”

Training and Safety

At CompuCycle, all employees are background checked and drug tested. The company uses hiring agencies that are familiar with their facilities—they have visited and know exactly how the company operates. They also know the type of people they are looking for. For certain positions, the company gives possible hires a survey to see if they can fill that position and once a new employee comes onboard, they are trained in that position for a certain number of weeks by a key person in the area in which they will be working.

As a key component within the organization, safety is always a priority. In addition to wearing the correct safety clothing, employees are trained on how to safely process material and operate the equipment as well as told if you do not know how to do something, ask the supervisor. With different sections within the company’s processing facility, each one has a manager on the area’s working floor. “We perform safety inspections, hold monthly safety meetings, and hold job assessment meetings every day. There is a safety process each employee goes through before drivers can collect the equipment. We also ensure that they have the right equipment. In the event that they do not, we will reschedule pickups. We will not compromise our employee safety at any time. It is a safe environment,” says Clive. With access control throughout the facility, including secure lockers, an employee breakroom, camera surveillance throughout and 24-hour security at the facilities, CompuCycle’s trucks also have GPS monitoring and are locked when they are not in use. Management is alerted if the trucks are idle for a period of time, unlocked or leaving. In addition, employees cannot go into areas where they are not working.

Community Outreach

Working closely with the city of Houston and handling their assets, CompuCycle also offers a program for residents to drop off their materials and electronics, cost-free, to their facilities during business hours in order to get them to recycle responsibly and securely. During the first Saturday of the month, the company holds residential collection events in the North Houston area of Kingwood and on second Saturdays, CompuCycle holds an event in the Southeastern Houston area of Clear Lake from 9am to 3pm. “We have been doing these events throughout the year for the last several years and they are very well attended by residents. We work with the local ABC-13 channel to promote recycling events. We collect about 128,000 lbs. per year. In addition, during Earth Month (April) and America Recycles Day (November), we participate in area community events,” explains Clive. “For our corporate clients, we hold bi-annual collection events where the company’s employees can bring electronics from home to be recycled.”

“Schools also want us to come out and speak on behalf of the importance of electronic recycling especially around Earth month and America Recycles Day, but we really try to do as much community outreach as possible because we feel it is important to be there and show what we do and how we do it responsibly,” says Kelly.

Addressing Market Trends

Clive stresses that the company is always looking for market trends and what is going on with the competition. Electronics recycling is still a fairly young industry and there continues to be changes and tremendous competition. CompuCycle also looks at longevity and continues to build their business relationships that have been nurtured for a number of years. By providing the number of services, security and the correct processing and downstreams to recycle, they have stayed ahead of their competition. Although it is a constant challenge, their key clients and customers understand the industry and its impact. “Education is such an important theme that we have made that a priority not only with our newsletter, but also across all of our social media channels because it is a key component and we are all about continuous improvement,” says Kelly “We have to always be on our feet and able to improve as well as be more sustainable.”

Clive agrees, “We send out monthly newsletters to our business prospects and current clients about the industry, educating them on the dos and the don’ts, the challenges, the benefits, what is happening and what they should be on the look out for because not everyone behaves in the same way. In addition, because there is also a lot of collaboration in our industry, many electronic recycling companies are now sending their products to us because we are a downstream solution that they can use. From an economics and logistical standpoint, it makes more sense for them to do it that way. Even though we compete in many areas, we have this particular niche that they do not and we help them out.”

Looking Ahead

Within the next year, CompuCycle is looking to not only add one additional shift in their shredding facility, but they will also be working on educating the community and legislators regarding the importance of electronic recycling. In the U.S., 80 percent of e-recycling is ending up in landfills, therefore, CompuCycle will work with environmental organizations to focus on trying to get the legislators to recognize the process of e-recycling as opposed to landfills.

Clive points out that he is very proud of the CompuCycle family because without everyone working well together, the company would never be as successful. “While I am fortunate to be working together with my wife, Kelly, it is the team of people that we have surrounded ourselves with that have helped us grow. We are a recycling company that provides value-added services to customers through electronic recycling and materials processing as well as responsibly and safely destroying data, so they do not end up in the wrong environment. We are happy to be living up to the expectations that our clients have for us.” | WA

For more information, visit www.compucycle.com.