Preserving our water supply goes beyond the needs of specific project. It is a priority for all and should be taken seriously. When you implement a Water Conservation Program, you are contributing to the public good.

Steve Clark, PhD

Of all the natural resources being taxed by the needs of the modern world, perhaps the most important is the continually expanding demand for water resources. As water becomes scarcer, and increasingly important, new technologies are needed to find innovative ways to preserve this precious resource. In Chile, for example, the mining industry is investing billions of dollars to build desalination plants and pipelines; bringing ocean water as far as 200 kilometers inland to meet their demand and maintain operations. It is a full-blown crisis for that nation and a top priority for their government and economy. It has been reported that world water consumption will increase by 40 percent in the next 10 years, representing nearly exponential growth. In the U.S., as more and more communities continue to be built, more drain on the current water infrastructure is created. For 25 percent of people and operations that rely on water from aquifers, this source is being consumed at a rate that will create significant problems meeting the demand in as few as two generations.1

Water and Your Landfill: A Proactive Approach

When it comes to controlling dust at your operation, whether the actual landfill, a transfer station, or another ancillary area, what are the options? We know watering is not the answer, but at the same time, we need to prevent dust from flying to insure a safe environment and keeping our skies clear of pollution, for both regulatory requirements and neighbors. Creating a Water Conservation Program instead of looking to buy the first dust control product off the shelf is a first step to conserve water and, at the same time, maintain the operational demands and environmental standards for a given site.

The concept of a Water Conservation Program is straightforward enough. However, the process of effectively constructing and executing a program is quite involved. When undertaking a program, each manager needs to work with their team and their partners/vendors in analyzing the following elements:

- Site Expectations—It is important to understand how to balance your internal standards with your regulatory requirements, as well as how to keep your neighbors satisfied.

- Site Aggregate—Variations in native soil, such as clay content or gravel levels, greatly affect the approach that will yield highest results.

- Climate—Relative humidity and seasonal variations are critical to achieving predictable results through product choice, application frequency and timing.

- Daily Traffic—The type and frequency of traffic is an essential variable for site management.

- Environmental Responsibilities—If you have additional, specifically defined responsibilities, the approach to your site may vary.

- Budget—While efficiency is the goal of any program, some sites will have more stringent restrictions than others.

- Current Usage Rates—Document and understand where you’re starting from, both with water and supporting products so that effective measurement of results is possible.

An effective evaluation may reveal immediate gains available to the project that were previously overlooked. In many instances, however, a manager may need to further educate themselves on other products available in the marketplace and how they differ in performance and application. A product that has a more efficient application rate and responds to recharge efforts may be more expensive at first pass. Understanding a longer term use of the product, as well as factoring how water resources can be saved may reveal that it’s effective, or applied, cost is lower than a commodity. For this reason, it is also important that partners and vendors working on the project use sound science that can be quantified and demonstrated to the manager. It is not enough to accept claims purported in marketing materials, or to reference a single project that may only have a few similarities to the one being worked on. The effort needs to be collaborative so that the partner has a comprehensive understanding of your specific project and can then make informed recommendations on how a program can be constructed. These background materials and preparation efforts will not only help determine the optimal approach, but can be used as supporting documentation when describing the program to higher ups or other constituents. As growing scarcity of water continues, increasingly sophisticated ways of measuring cost and usage will be required, and designing a program is an excellent step in this direction. A sound Water Conservation Program considers the long-term result of reducing water use and creating a dust-free environment based on all variables while maximizing budgetary efficiency.

Starting a Program

If your landfill or transfer station needs a Water Conservation Program, your first step is to start researching companies capable of bringing you the expertise needed to make the proper assessments. These programs are relatively new in many areas, so be prepared to ask the questions that will give you confidence in the partner you select. Most notably, your prospective partners should have a comprehensive understanding of the list above and include each of those factors as you begin assessing your possibilities. For any further information or get any questions answered, work with an established partner. Preserving our water supply goes beyond the needs of specific project. It is a priority for all and should be taken seriously. When you implement a Water Conservation Program, you are contributing to the public good.

Steve Clark, PhD is a Technical Service Representative for EnviroTech Services, Inc. (Greeley, CO). He joined ESI in 2012 having worked as a chemist in the field of surface science and as an information officer in manufacturing. Using his analytical chemistry background, Steve brings instrumentation expertise and testing methodology development to the ESI research group. His current emphasis is to extend laboratory experimentation to the field using remote instrumentation and video monitoring. He can be reached at (800) 369-3878, via e-mail at [email protected] or visit www.envirotechservices.com.

Note

- Is Water the New Oil: HBS Panel of Experts, Overview.

Sidebar

Water Conservation Case Study: Larimer County Landfill

Larimer County Landfill sits on the border of the Ft. Collins city limits. With the desire to be a good custodian of the city’s resources and improve efficiency, the director of the landfill was seeking methods to reduce water use and control dust generated on the landfill roads. Water was the only method of dust control and the water being consumed was provided directly from Ft. Collins Utilities. After meeting with EnviroTech Services, the director made the decision to try an innovative method of dust control. EnviroTech’s Water Conservation is a maintenance program that uses a humectant product, X-Hesion Pro (XPro). The general concept of the program is to use this unique product as an element that gets introduced to the site roads in such a way that it actually becomes part of the road base, as well as an added element of the water being applied. The effect, as was demonstrated in this case, is that water usage is reduced by furthering the effectiveness of water each subsequent time it is applied.

As is necessary for any successful effort, the assistant director of the landfill was directly involved in the program plan, supervised the initial application, has been available during dust meter readings, and added the appropriate amount XPro to the water truck when needed. The involvement of the landfill’s management was critical so that multiple factors could be actively monitored and considered throughout the program. For instance, knowing how much and when to add XPro to the water truck is similar to changing the oil in your car. If the weather conditions are hot and windy, the frequency of adding XPro will be increased (much like driving a thousand miles week will increase the frequency of your car’s oil changes). The opposite is true if the weather is cool and wet; less water and product are needed. As with any topically applied product, rain will affect this program. A light rain is good and rejuvenates the existing XPro in the road. Heavy rainfall can wash most products from an unpaved road, but we have seen XPro continue to have dust-reducing effects after a 3 inch rainfall. All these elements require someone in charge of the site paying attention, so that they can be properly accounted for. While not every site or manager will have access to dust meters or other advanced testing measures, visual inspection and tracking can still be relatively effective. Equally important to the hands on management of a program, of course, is selecting the product that will complement the water itself. As a humectant, XPro ‘likes’ to hold onto water. When incorporated into the surface of the road, XPro causes loose material to become heavier. The dust created by traffic does not plume as much; it quickly drops back to the road. A key to controlling dust is knowing your road and the different dust levels produced on them. Active involvement by onsite personnel saves on equipment maintenance, fuel and time.

Location

The initial application occurred at the Larimer County Landfill as seen on see Figure 1. The image from 2012 is used as a reference. The red line is the road to the dumpsite and the blue line is the road for the scraper. After meeting with the assistant director, the scope of the area to be treated was established. Road sections included:

- Haul Road (red) 32’ x 5280’ (~18,773 yd2)

- Scraper Road (blue) 32’ x 2640’ (~9386 yd2)

- Variable width of roads but were measured to average at 32’

- Road was measured by driving since Google maps are two years old

- Road base is native aggregate with some asphalt millings on first ½ mile of haul road.

- Expected traffic profile

- ADT (variable/unknown amount heavy of traffic)

- Platform: NOT TREATED

Figure 1

Initial Application

The initial application was completed using EnviroTech’s applicator truck. For the first treatment, a quick buildup of the humectant product was needed, so ESI sprayed a 50 percent mixture of water and XHesion Pro. The larger dose of Pro greatly decreased the water evaporation and made future applications by Larimer County Landfill’s water trucks less frequent. A complete cost savings analysis was performed, it showed the initial application paid for itself (see Figure 2).

Figure 2

The Program and Truck Water Applications

After the initial application, the road was maintained with water applications and water with XPro applications (see Figure 3). With two days between the initial application and the beginning of the next week, it was anticipated that a light water would be needed. This water lasted noticeably longer than a regular water application (see Figure 4). Temperature and humidity are prevalent factors on the frequency of the application of product, at the beginning of this program a 10 percent application early in the morning for the first week was recommended. The 10 percent Pro/Water mixture was be mixed at a fill station the Landfill was able to set up (see Figure 5). At the Larimer County Landfill and for the first few product/water mixes, a representative from ESI lab was present to ensure quality control. After the first week, a schedule of a 10 percent application every other day was recommend during hot summer days (see Figure 6).

Initial Application (August 16, 2014, 5:00pm)

After the dilution, the main haul road was treated at a specified application rate at a width of 14 feet. Each lane was treated completely from the end of the pavement to the platform where the refuse is deposited. It was decided that the area near the platform would not be treated due the heavy traffic and the rapidly changing location of the deposit area.

The First Two Weeks

The earthmover changed areas on the property and was no longer using the treated scraper road. Notice the dust generated by the scraper on the untreated road on the left and the lack of dust on the treated road on the right (see Figure 7 and 8). Over the weeks of 8/17 to 8/31 on the treated sections, water was only applied once a day down from six times and the product was used only twice during the 14 day period.

The Third Week: September 1 – 6

During the site visit on September 2, the water truck was out on the property watering untreated roads. The main haul road had not been water in two days and showed signs of very little dust (see Figure 9 and 10). With the success of the program during the first three weeks, expanding the program onto other roads of the property was discussed. The water truck would be ‘doped’ with 20 percent to 30 percent XPro and begin the process of building up the humectant material in the previously untreated roads.

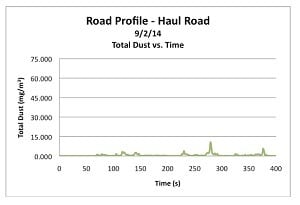

Quantitative Dust Data

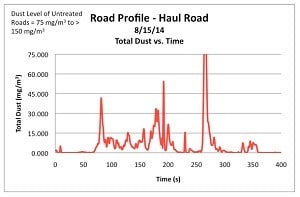

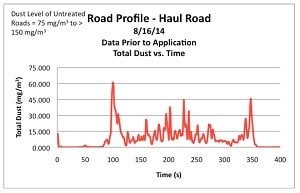

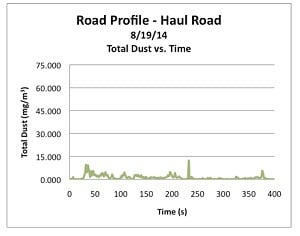

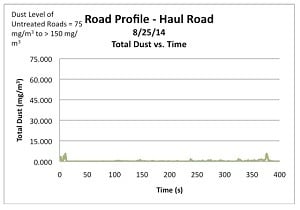

While the assessment of a program’s effectiveness can be largely ascertained through visual observation, as demonstrated above, it is ideal to use measuring equipment to further confirm and quantify results. Figure 11 to 15 show a sampling of charts generated from the data collected. The data confirms the visual observation from the site.

Haul road one day prior to the application.

Roads had been watered prior to measuring the dust.

Haul road minutes before the X-Hesion Pro Initial Application.

It is important to remember that dust is becoming visible above the measurement of 10. This road is very dusty at the day’s end.

Haul road three days after the application.

Haul road nine days after the application and two 10 percent ‘doped’ water trucks.

This measurement was prior to the roads being watered.

Conclusions

Clearly, both visual and quantified data confirm that the program was greatly effective at reducing dust at the Larimer County Landfill. However, this was a water conservation program, so it needs to also reduce water and be financially advantageous. Detailed financial metrics from the landfill are being finalized, and we know that prior to the application of X-Hesion Pro, four to six truckloads of water were being used a day. After the application, one to two truckloads of water were used. So, a savings of water, equipment usage and personnel time ranges immediately from 50 to 80 percent.

The Water Savings Scenario

The Larimer County Landfill operates six days a week. We have monitored water use and have seen as little as one water truckload applied to control the facility’s dust. From a conservative perspective, the water truck driver would have four free hours per day to be used on other landfill projects. That is like gaining one halftime trained employee without additional expense. It is difficult to document this savings and increased productivity, but it is existence will be felt. After the initial application, the average amount of product being used at the landfill per week is equal to about one application (~350 gallons). Knowing that prior to the X-Hesion Pro application, six truckloads of water per day was reduced to two truckloads applied, the savings to the landfill would be:

21,000 gallons (Historical, six truckloads)

- 7000 gallons (Present, two truckloads)

x 6 days a week of dust control

= 84,000 fewer gallons of water a week

Operating 52 weeks a year and under this scenario, the landfill could see a water savings of more than 4 million gallons of water/year. The Program at the Larimer County Landfill was a very strong example of an involved and proactive site partnering with a supplier familiar with how to manage the site variables and creating real, measurable value for the end user. This can be an example of how to approach a program of your own.