All waste and recycling haulers should re-evaluate how they use lubricants so as to protect equipment, save time and money and reduce emissions.

By Alec Taylor

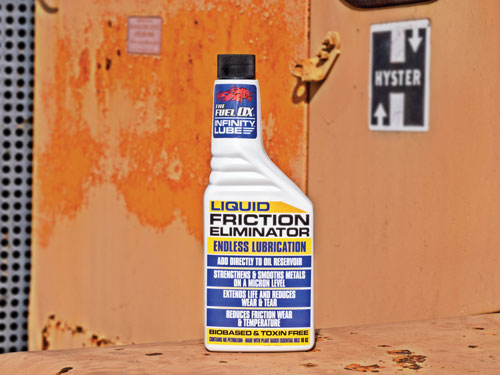

Photo courtesy of The Fuel Ox.

This time of year, fleet owners are gearing up for both treacherous winter weather and the busy holiday season. Estimates show that Americans produce 25 percent more waste and recycling between Thanksgiving and New Year’s Day. That means heavier and more frequent hauls, putting pressure on the engines at the heart of a hauler’s operation.

As fleet managers look for ways to drive efficiency and maintain their fleets, they should not overlook an important component: lubricants. Waste and recycling haulers rely on big, heavy vehicles that are constantly stopping and starting—all activities that use more energy and cause wear on engines, which can lead to costly downtime.

Using lubricants, in the right place and at the right time, can improve engine performance, reduce frequency of oil changes and other maintenance steps, and reduce

emissions. Following, are a few places to start.

Oil Reservoir

Applying an oil additive to your oil reservoir can reduce frequency of oil changes and keep oil cleaner, which reduces the wear inside your engine and makes disposal easier and less toxic (as the additive can reduce the metals and caustic acids that can accumulate in the crank case). Many fleet owners overlook this important, easy step, as they mistakenly believe that the engine oil alone will keep engine parts running smoothly and will help maintain its lubricating integrity. Today’s engines are much more demanding than their predecessors and keeping the oil free of contaminants is vital to increasing their longevity.

A specially designed oil additive is necessary to reduce the toxic metals and protect the friction points, essentially smoothing out the layers of metal, keeping the pitted, oxidized and corroded metal out of the engine oil.

Cleaner engine oil is better for both the engine and the environment. Most lubricants can be poured directly into the reservoir during oil changes.

Chassis Fittings, Bearings and Springs

Everyone knows that lubricating grease should be used regularly on the parts of the truck assembly where metal comes into regular contact with metal, especially during the time of year when they are under more pressure to work harder. Grease on these components keeps the equipment running without breakdowns, and the effective, regular greasing can reduce the energy needed to operate equipment. That means less fuel needed to move the vehicles, and less carbon emissions. Some specialty greases have been proven to reduce the wear significantly, thereby, extending the life of the parts.

Many fleet owners apply grease on a regular basis, sometimes as frequently as once per day up to once per month. While that is okay, it is best for maintenance teams to carefully evaluate reapplication times more meticulously. Newer products with advanced technologies require fewer applications, which saves money and time for maintenance.

All Exposed Machinery and Metal Components, Including Chains and Cables

Everything from nuts and bolts to all parts that are exposed to the elements benefit from a good lubricant—especially those components exposed to water, to reduce friction and corrosion. During the winter months, it is particularly important to protect them from rusting and freezing.

This is especially true for waste haulers during this busy season, when specialized equipment may be rolled out to manage the transport of everything from Christmas trees to compost piles to tons of extra cardboard from holiday gifts. These seasonal pieces of equipment are the first to be neglected, so a high-quality lubricant is imperative to insure their proper maintenance. All waste and recycling haulers should re-evaluate how they use

lubricants so as to protect equipment, save time and money and reduce emissions. | WA

Real-Life Savings

Real-Life Savings

At Industrial Sustainability Group, they work with customers across the country to offer specialized solutions for their needs, including a major waste and recycling hauler on the East Coast, which has switched over to their Infinity Lube™ suite of products for their greasing and lubricating.

Using Infinity Lube™ Liquid Friction Eliminator in oil reservoirs can triple the length of time between oil changes, which is a savings of many thousands of dollars on maintenance costs for customers, while also increasing productivity for each vehicle. In addition, customers are seeing dramatically fewer issues with metal engine parts and components, which is also leading to better longevity for vehicles.

Alec Taylor is co-founder and Director of Operations for Industrial Sustainability Group, or ISG, which distributes Fuel Ox® and Infinity Lube™ products. A graduate of Bates College, he founded ISG with his father, Rand Taylor, in 2014. He can be reached at (908) 747-2720.