Safiye Tanrıverdi

Electronic waste or e-waste are materials that are formed when electronic devices that have completed their useful life are scrapped by not fulfilling their function. The area covered by electronic waste is very wide. Nowadays, it is indispensable in almost every device used in daily life and vital activities, in business life and even in every activity.

Depending on the global consumer demand, with the rapidly developing technology in the world, the production of electrical and electronic vehicles is increasing, and their usage periods are shortened. Large household appliances, small household appliances, information and telecommunications equipment, lighting equipment, electrical and electronic devices, toys, sports equipment, medical devices are called in e-waste.

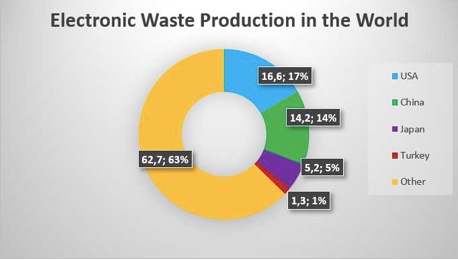

Global E-Waste

Globally, the world generates 50 million tons of e-waste annually. This value is equivalent to 6,000 Eiffel Towers and grows at about 5% each year. In 2016, Asia produced the largest amount of e-waste with 18.2 million tons, while America produced 11.3 million tons, Africa 2.2 million tons and Oceania 0.7 million tons.

According to the BBC future, Europe is the second highest producer of e-waste in the world, throwing 12.3 million tons of electronic equipment and batteries annually. These wastes contain approximately 300,000 tons of copper and 30 tons of gold. According to research, old equipment contains more of these metals than new devices, so if recycle all of them, it will be more than enough to produce 14.3 million tons of new electronic equipment and batteries that Europeans buy annually. By recycling these materials stored in our old devices, it is possible to recycle and reuse in new devices without the need for mines.

Urban Mining

Urban mining has become a trend today in terms of high value materials per ton compared to traditional metal ore mines. As urban societies constantly generate waste, 75% of the world’s waste is generated from industrialized urban areas. These wastes contain more minerals and metals than primary sources. For example, sewage sludge has been found to contain more gold and copper than many mines operated.

Urban mining requires 17 times less energy to extract these metals than obtaining primary source materials, according to the Norwegian research institute. It has been found that the cost of extracting large amounts of gold and copper from the waste television is lower than the cost of extracting the metal from the mine site.

The main obstacle to the full spread of urban mining and a sustainable economy includes some important social and health problems and technical difficulties. One of these technical problems is that metals cannot be recycled indefinitely. Because losses are impossible. However, Proses Makina Company offers all turnkey machinery and chemical solutions for precious and rare metal recycling and treatment system for e-waste and scrap types.

Another problem is access to ore in urban mining. It is not stocked in a certain area like a mine, it is located in a large area hidden and difficult to reach in our house. Since consumers are not conscious of collecting and delivering old electronic devices, overcoming these difficulties will be solved by educating the population on this issue.

With the recycling of electronic waste, which is one of the environmentally friendly actions, we can start to solve this global problem at home, and we can start to prevent environmental problems with the logic of reduction and reuse.

E-waste Recycling

As a result, e-waste has become one of the fastest increasing waste streams worldwide. Due to the electronics end of life, e-waste has gradually become significant source of precious metals. For instance, computers and televisions tend to be the electronics with the most gold in them, but camcorders, media players, game consoles, and cell phones also contain gold.

Its profitable to recycle gold from electronic devices because it makes your outdated electronics so valuable even after they have reached the end of their life cycle. Therefore, it is necessary to recycle PMs from end-of-life products, realizing the sustainable development of precious metals. Proses Makina Company establish turnkey facilities that enable the recycling of electronic waste and the recovery of metals such as gold, silver, palladium, and copper. With the right process, it is possible to recover precious metals with high efficiency.

Precious Metals in E-waste

Electronic wastes encountered in every field contain precious metals. Their recycling becomes more important due to their gold, silver, palladium, and copper contents. It is more profitable to recover these precious metals from waste rather than mine production and requires less labor and energy.

Of course, electronic waste in such different areas cannot be expected to be in the same amount in all types of precious metal content. Although it is not known precisely, the precious metal content varies according to each type it and even the brand of the product.

For example, television cards do not contain much precious metal content. It is unlikely to bring profit when recycled is desired. In addition, the best material in terms of precious metal content is ceramic CPUs. Motherboard, ram, and printed circuit boards come after.

In electronics industry, gold and silver are used as contacts, bonding wires, and switches, while palladium is used in computer hard disk drives. In 2015, global demand for gold, silver, and palladium in the field of electronics were 254 tons, 12.816 tons and 40.18 tons, respectively. Gold (Au)– Printed Circuit Boards, Computer Chips (CPU), connectors / fingers, connector plating, pins, contacts, EPROM, ROM, RAM, IC, transistors, diodes, switches.

Gold (Au)– Printed Circuit Boards, Computer Chips (CPU), connectors / fingers, connector plating, pins, contacts, EPROM, ROM, RAM, IC, transistors, diodes, switches.

Silver (Ag)– Printed Circuit Boards, Computer Chips, keyboard membranes, some capacitors, batteries, solders, switches, relays, USPs, stabilizers, contacts, RFID chips, PV cells

Platinum (Pt)– Hard Drives, Circuit board components, HD, thermocouples, fuel cells, sensors, switching contacts.

Palladium (Pd)– Hard Drives, Circuit board components (capacitors), multilayer capacitors, connectors, transistors, diodes, Ag-Cu-Pd solder

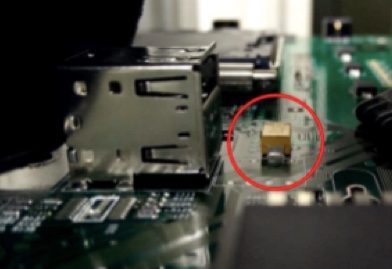

Tantalum Capacitors in E-waste

Tantalum capacitors found in printed circuit boards; It is commonly found in notebook computers, the automotive industry and cell phones. It is mostly soldered to the surface of the circuit board. This surface-mounted tantalum capacitors occupy much less space on the printed circuit board and have long-term durability, which is a major factor in being preferred like other electronic components.

While the tantalum capacitor ratios that can be visually defined in the studies carried out are 8 grams of tantalum per 1kg in printed circuit boards found in laptop computers, this rate is 3 grams in hard disk drives. In contrast, smartphones follow with the lowest Ta value of 1.5 g / kg.

While the highest tantalum potential per unit is found in laptops and servers above 1 g Ta, the highest potential in PCBs is in hard disk drives, laptops, and mobile phones. The smartphones and tablets reviewed have the lowest amounts.

The Proses Makina team, performs the recovery of Tantalum, which has a high economic value from printed circuit boards and precious metals, with chemical operation and lower cost, with the highest efficiency, has developed the alternative methods and equipment while its technical team provides support to its customers.