Newly-certified under ISO 45001 under OHSAS 18001, ecomaine is focused on moving ahead with even more employee involvement on safety, ongoing engagement by management and aggressive outreach and education on contamination issues.

Originally named Regional Waste Systems, ecomaine was founded in 1976 by four southern Maine municipalities—Portland, South Portland, Scarborough and Cape Elizabeth—in response to a Maine law that called for the closing of privately owned landfills. Two years later the group purchased 240 acres for a jointly owned landfill, now 274 acres located between Scarborough and South Portland, and bought a baler to satisfy their processing needs. By 1985, the municipally owned, non-profit organization had grown to include 20 municipalities, who had seen the value of a regionalized strategy toward waste management.

ecomaine’s waste-to-energy plant was built in 1988 and provided two major benefits: 1) use of municipal waste as fuel to generate and sell electricity for the financial health of the organization, and 2) reduction in the volume of trash by 90 percent to greatly extend the life of the landfill. Today, the WTE facility continues to sell electricity generated from MSW, generating revenue for ecomaine and the surrounding communities; similarly, the MSW continues to be reduced by 90 percent in volume, extending the life of the landfill. Additionally, due to upgrades in controls, the WTE plant operates more efficiently and cleaner than when it was installed 30+ years ago.

Recycling was added in 1990 and single-stream recycling was added in 2006 for both environmental and financial considerations that have succeeded beyond expectation—to the tune of more than 35,000 tons of single-sort recycling per year. Rather than being involved in collection, ecomaine communities contract with hauling companies who transport the material to the organization for sorting/processing at their single-sort MRF.

Currently employing 80 staff across its single-sort recycling facility, waste-to-energy operation, landfill and administrative offices, ecomaine has grown to include 70 communities in Maine and New Hampshire with more than 450,000 people under contract for services. It has earned the International Standards Organization certification for excellence in environmental management (ISO 14001) and safety (ISO 45001) for each of its three facilities. ecomaine processes about 175,000 tons of municipal solid waste per year and employs four full-time education and public relations staff to support sustainability in each of its programs.

every year.

Keeping Proactive in Uncertain Times

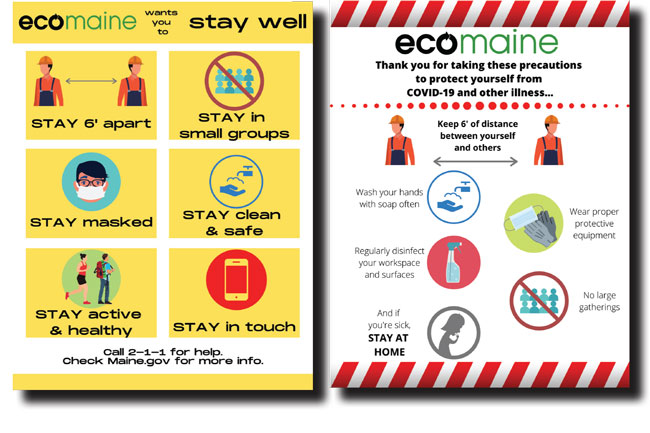

As an essential service, ecomaine has definitely taken steps to keep workers healthy and safe by following the State of Maine CDC guidance from the start of the pandemic. However, perhaps most significantly, is that they are practicing “physical distancing” of more than six feet. “We started by documenting any incidents of contact within that six-foot zone, and having supervisors review, summarize results and sign off on these activities—a step which the Director of the Maine CDC called ‘exemplary.’ Aggressive and intensive physical distancing is the most important way to reduce transmission, and it also encouraged mindfulness about keeping appropriate distance as well,” says Kevin Roche, ecomaine’s CEO and General Manager.

Ecomaine employees not only wear the appropriate personal protective equipment, including hardhats, safety glasses, gloves, masks and Tyvek suits, but they have also sanitized and disinfected their facilities even more than before, with both an external firm coming in to do a deep clean, as well as taking on temporary staff to conduct additional “cleaning loops” of highly trafficked areas. In addition, each staff member is asked to disinfect and wipe down surfaces they touch and ecomaine is promoting vigorous and frequent hand washing. Plexiglas was also installed at ecomaine’s scale house and employees received periodic updates from organizational leadership with resources on where to get information, as well as posted signage throughout facilities, which is updated periodically.

The organization also made sure that it took care of its employees. “From April until July 2020, ecomaine provided free lunches to all employees to discourage them from visiting stores or restaurants. We also provided 40 additional hours of sick leave to be sure that sick employees would stay home from work and offered employees who could do their work from home the chance to do so when possible. Meetings have been switched over to remote meetings using the Zoom platform,” explains Roche.

Recycling and Contamination Issues

As has been the case with other MRFs, ecomaine has been challenged by contamination in the recycling stream. However, through aggressive outreach and education, ecomaine has seen contamination fall from above 20 percent down to between 10 and 12 percent. “In addition to education in schools, on social media, news stories and even paid advertising, we employed a team of interns to implement an ‘oops tag’ curbside education program in 2019 that helped dramatically decrease contamination. This program continues today,” says Matt Grondin, ecomaine’s Communication Manager. “We have also just begun a ‘Master Recycler’ course to provide a deep dive educational opportunity. It is a self-paced, six-month course (with available guidance from ecomaine staff) that will culminate in becoming a “Certified ecomaineiac” expert recycler. We will run it from April to December of this year, and more than 80 spots were full within four days, with a wait list of 50+.”

Throughout the recycling market downturn, ecomaine has been active in encouraging Maine municipalities to stay the course, and not give up their recycling programs. Through media, education, community stakeholders and advocacy for good waste management policy at the state capitol in Augusta, the organization has made the case for keeping recycling on track. These strategies have worked well and ecomaine has stayed quite level in their tonnage and number of communities over the past few years. Continues Grondin, “We provide robust education opportunities to all of our communities, and although we have lost a couple of contracts, we have gained others as well—our membership has been very stable, due to our transparency, educational offerings and willingness to work with our communities.”

Throughout the recycling market downturn, ecomaine has been active in encouraging Maine municipalities to stay the course, and not give up their recycling programs. Through media, education, community stakeholders and advocacy for good waste management policy at the state capitol in Augusta, the organization has made the case for keeping recycling on track. These strategies have worked well and ecomaine has stayed quite level in their tonnage and number of communities over the past few years. Continues Grondin, “We provide robust education opportunities to all of our communities, and although we have lost a couple of contracts, we have gained others as well—our membership has been very stable, due to our transparency, educational offerings and willingness to work with our communities.”

Currently, ecomaine is dealing with the increasing prevalence of lithium-ion batteries that represent a real threat to waste management facilities. “ecomaine has invested heavily in fire suppression systems, including a water cannon and thermal imaging system, but these kinds of batteries are more and more in everyday devices,” Kathryn Oak, ecomaine’s Recycling Manager. “As waste managers, we are a reflection of our society and culture; the more of these kinds of batteries there are, the more likely we are to face those challenges.”

Another challenge is the decreasing lifespan of landfills, particularly in New England. “We’re seeing more and more landfills, especially in southern New England, reaching capacity. As a result, too much waste is traveling too far to be landfilled in states thousands of miles away. This isn’t a sustainable option fiscally or environmentally. We must work on being able to divert, capture and recover more of our solid waste before it becomes an unmanageable prospect,” Roche says. In response, ecomaine promotes the higher rungs of the solid waste hierarchy in their business decisions. Through education, they emphasize reducing and reusing, as well as recycling and composting/digestion. They also offer grants to schools to reduce the amount of waste being sent as trash where possible.

Adds Roche, “We operate a MRF for recycling, and we have a food/organics program to remove that from the waste stream, so, we don’t landfill as much; we reduce MSW by 90 percent through waste to energy. This keeps waste levels lower and more manageable right here in Maine.”

Connection to Communities

In Roche’s view, the most outstanding and unique achievement is the commitment and connection to ecomaine’s member communities by working closely with each of their municipalities—20 of whom have seats on the ecomaine Board of Directors—to increase the level of transparency, trust and positive perception of what ecomaine does and stands for. For example, ecomaine’s response to the COVID-19 pandemic was quick thinking in a fluid, fast-moving situation. This resulted in ecomaine’s members inherently trusting the organization to respond quickly, appropriately and safely, in order to keep Maine’s waste management systems operational and safe.

ecomaine’s leadership in staying the course over some rough times in the recycling markets is also an important achievement to them. “While prices for post-consumer materials fell, ecomaine was committed to the long-term view that markets would rebound. We knew that jumping in and out of the recyclables market was more detrimental to our residents’ habits than a short-term price gain was worth. In the end, ecomaine lost very few recycling customers, and is positioned well to expand again with improving markets in the future,” emphasizes Oak.

collection workers.

Exciting Expectations

2021 will be an exciting year at ecomaine. Thanks to thevision and support of ecomaine’s Board, the waste-to-energy plant continues to be maintained and functions now more efficiently than when it was built 32 years ago. State-of-the-art updates keep the plant working economically and environmentally friendly. The organization is currently on track to replace two diesel trucks with all-electric waste hauling trucks this fall, which will be exciting in its own right—these trucks will also be powered directly by the waste-to-energy plant. “We are very enthusiastic that these trucks will be hauling waste and powered by waste! We estimate that our cost savings on diesel fuel will be about 75 percent, and it’s also a more cost-efficient use of our generated electricity as well. We are continually looking for ways to better use the resources we have, and in this case, the electricity we generate from solid waste provides the ability to use this new technology,” says Roche. “It’s a great prospect for our member communities, too. As a regional, collaborative organization, ecomaine—through a grant from the Maine Department of Environmental Protection and the federal EPA—will pilot this machinery, with the hope of learning more and sharing information on this emerging technology with our partners.” Additionally, ecomaine will be using 40 acres of landfill space to generate five megawatts from otherwise unusable brownfield property. “Maine’s solar landscape has changed quite a bit in the last two years, and it now makes a lot of sense to use this technology to generate clean energy and revenue for the organization,” adds Roche.

He says ecomaine will also continue to strive for excellence in their other environmental and safety programming. Newly-certified under ISO 45001, an even more rigorous standard than previously, under OHSAS 18001, ecomaine will move ahead with even more employee involvement on safety, increased involvement in safety by temporary staff and the public, and ongoing engagement by management. Says Roche,

“The trust that ecomaine will meet high expectations is something we hold as a truly significant achievement.” | WA

For more information, contact Matt Grondin, Communications Manager, at (207) 773-1738 or e-mail [email protected].