The safety of a fleet lies on the responsibility of a fleet manager or owner. In order to create a successful safety culture, the fleet must be equipped with the proper tools and also provide guidance and training.

By Amy Ahn-You

Working as a refuse collector has long been categorized as one of the most dangerous jobs in the U.S., ranking #5 in 2016. This statistic has driven safety to the top of the priority list for most, if not all fleet managers. Refuse collectors and waste haulers work in demanding and dangerous environments on a daily basis. Though they take the same or similar routes every week, each day is never the same. From environmental changes, to other vehicles, pedestrians and cyclists on the road, the collectors and operator have to remain alert and aware of the refuse truck and their surroundings. A safe fleet starts from the top down. Fleet owners and managers can take measures to ensure the safety of the fleet and the haulers.

Create a Safety Culture

Creating a culture where safety is a priority is essential. Clearly communicating this to your organization will be a critical component in successfully implementing relevant policies and gaining the support of team members. While work must be done efficiently, an employee’s welfare and safety should always the most important factors in any company environment.

Collaborating on a solution is essential to creating and fostering a successful safety culture within your fleet. Great ideas for risk reduction and injury prevention often come from employees because they are faced with the everyday challenges of the job. The safety planning process should include waste and refuse collectors throughout the entire process. Fleet managers and truck operators must work together to keep the team safe.

Creating and/or updating a safety plan for your fleet does not have to be a daunting task. Focus first on preventing the most common and preventable injury types, such as back, shoulder, or arm/handover exertions or strains. The cause of these injuries is most often getting struck by or against objects, motor-vehicle crashes, and slips, trips or falls.

Creating a culture of safety is a smart company investment. Taking measures to reduce risk will directly decrease employee injuries, the amount you pay in disability benefits, and the chance of a costly lawsuit. Creating a culture around safety will also increase employee morale, loyalty and work efficiency.

Implementing Fleet Safety Technology

When a driver of any vehicle steps behind the wheel, they are responsible for themselves and their passengers, as well as pedestrians and motorists around the vehicle. Operating a large vehicle such as a waste truck can be a difficult task. The driver is faced with large blind spots, greater turning radii, and the challenges of driving in crowded urban and residential environments. It is crucial that the driver has a high level of awareness of the truck and surroundings at all times. With the use of safety technologies, this difficult job can become a safer one.

Collision Avoidance Systems

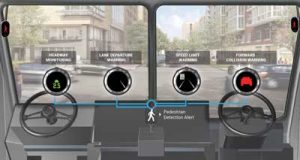

Fleets can take advantage of technology such as a collision avoidance system, which includes multiple types of alerts that warn the driver of a potential incident. Many of these alerts are featured in new passenger vehicles, but most fleet owners are not aware that the same technology can be installed on any type of waste vehicle. Using cameras as sensors to continuously scan the road ahead, these systems detect and calculate the risk of collision with objects such as vehicles, motorcycles, as well as pedestrians and bicyclists. Camera systems can also identify lane markings and even read speed limit signs. When a collision is imminent, the system emits visual and audible alerts in real time, giving the driver an opportunity to react, correct, and avoid a collision—or mitigate the severity.

Some collision avoidance systems are specifically tailored for large urban vehicles. These systems use an array of strategically placed vision sensors in order to alert the driver from incidents in front and on the sides of the truck, as well as dangerous situations including unintended lane departures or an unsafe following distance. The technology includes:

- Forward Collision Warning from rear-end incidents

- Pedestrian, Motorcyclist, and Cyclist Collision Warning in front and the sides of the truck

- Pedestrian, Motorcyclist and Cyclist Blind Spot Detection

- Lane Departure Warning

- Headway/Following Time Monitoring and Warning

- Speed Limit Indicator

Multi-Camera Systems

Camera and monitor kits can act as extra eyes and ears for drivers. The most commonly used camera is the backup camera used to show the otherwise “blind area” behind a vehicle during reversal. The camera feed is connected to a monitor inside the cab for the driver’s visual. The monitor stays off until it is triggered when needed. This may be sufficient for standard cars, but larger vehicles have many more blind zones to cover around the vehicle. New surround view camera systems provide a 360° aerial view of the vehicle and cover the immediate perimeter around the vehicle. This is achieved by “stitching” together the images from multiple cameras—typically four. This is a game changer for waste truck operators. With the use of a surround view system, immediate blind zones around the vehicle are eliminated and visible to the truck operator.

Telematics Systems

Telematics can be used to track and monitor vehicles in the field by using GPS and vehicle diagnostics. This technology can be used to optimize vehicle routes, improve driving behavior and help with preventative maintenance. The GPS sensors built into each unit can monitor the speed of each vehicle and detect whether the driver is accelerating too quickly or braking too harshly. Some can even tell whether the driver is wearing their seatbelt. The reports generated by telematics can be invaluable to a driver safety training program. They allow fleet managers to reward the safest drivers, identify those who need more training, and, in the worst-case scenario, create a paper trail for drivers who refuse to correct bad habits and can no longer be part of your team.

Video Event Recorders

Video event recorders are designed to serve two primary purposes: to offer video evidence in case of a collision, and as a personalized coaching and training tool for drivers. Mounted on the front windshield of the vehicle, these cameras are programmed to continuously record the view ahead and in the cab (and any additional cameras) as well as also trigger pre-configured event-based settings such as speed limit and G-force. In the case of a collision, the video offers incontrovertible evidence of what happened in the incident. The continuous video also sheds more light on not just collisions, but near-incidents as well. This serves to improve fleet safety by giving trainers and drivers real-life scenarios to review and how to prepare for them.

Video data provides driving coaches with the opportunity to tailor best practices to each driver. An additional safety feature that gives drivers peace of mind is the ability to manually mark an event when they feel an incident occurs that needs to be reviewed by a manager or supervisor.

All of these technologies are invaluable individually, and by implementing these technologies together, you are not only being proactive in working to improve your fleet’s safety, but you also have layers of security and safety for your team. These technologies mean further reduction in collisions through better driver training and management. In some cases, it can even mean avoiding litigation costs in the event of a false claim against a driver.

Use Data Insights

Hot Spot Mapping

Integrating a collision avoidance system with telematics provides the opportunity to identify where alerts occur and their frequency. A hot spot locator enables a crash frequency map to be generated in a point-and-click Web browser interface. This can be used by fleet managers when planning driver routes. Hot spot locations may be due to infrastructure deficiencies and could be avoided all together, or in the case of a municipality, a plan may be implemented to address these deficiencies and improve safety for its citizens.

Preventative Maintenance

The main objective of a planned preventative maintenance schedule is to improve the overall safety and performance of your fleet vehicles. Telematics keeps track of the same parameters that fleet managers use to create these schedules, such as mileage, fuel consumption and engine hours. These could be easily used to provide automatic notifications when it is time for a preventive maintenance.

Improving Driver Behavior

Provide Immediate Feedback with Real-time Alerts

Speeding, changing lanes without signaling and tailgating are common examples of bad driving habits. Collision avoidance systems provide drivers with real-time alerts when they exceed the speed limit, forget to use their turn signal or are at an unsafe distance from the vehicle ahead. Driving with the system installed, drivers become more aware of their behavior and naturally begin to adopt safer driving habits.

Training

Training begins with a clear understanding that policies are designed to protect the company, as well as employees and others on the road. It is not just a question of image and cost, but of saving lives. It is important to set aside some classroom time for new drivers as well as company veterans. Driver buy-in is a crucial element of any new safety initiative. It is important to meet with drivers and discuss possible implementation before adding new technology to the vehicles they operate. Creating opportunities for drivers to voice their concerns and offer suggestions can help head off inaction and complaints down the road, and they will likely bring useful ideas that have not been considered.

Last but not least, individual coaching is an indispensable component of driver safety training. These training meetings improve driver and supervisor relations while giving a chance for drivers to voice any concerns they may face on their route. It is important to maintain a regular schedule of one-on-one meetings, so drivers know they will be held accountable for misconduct and also be recognized for exemplary performance.

Driving Fleet Safety Starts from the Top

The safety of a fleet lies on the responsibility of a fleet manager or owner. In order to create a successful safety culture, the fleet must be equipped with the proper tools and also provide guidance and training. If the investment is made by the management and ownership, the same commitment will be reflected by the employees. The implementation of new products and technologies that keep operators and haulers safe on the job show a priority to the well-being of the team. Training, reprimanding and rewarding will ensure the safety culture stays at the top of the fleet priority list.

Amy Ahn-You is the Senior Marketing and Digital Engagement Manager at Rosco, Inc. (Queens, NY) and proud to be leading Rosco’s commitment to the global Vision Zero initiative. She can be reached at [email protected].