The Cumberland County Improvement Authority Solid Waste Complex in Deerfield, NJ uses a ROVAP™ Solution from Heartland Water Technology to evaporate challenging leachate reverse osmosis concentrate.

In 2018, Operators of the Cumberland County Improvement Authority, in partnership with their landfill gas-to-energy plant operator, Energy Power Partners, saw an opportunity to reduce the operating expense for the county’s Solid Waste Complex while meeting key sustainability goals for the Authority. By installing the Heartland Water Technology ROVAP™ leachate evaporation system (see Figure 1), the Authority has saved leachate reverse osmosis (RO) concentrate transport and disposal costs while increasing energy efficiency and reducing the environmental impact of the Solid Waste Complex.

The Authority

The Authority’s mission is the development, financing, and integration of projects, strategies, and initiatives integral to the sustainability of the economic and environmental future of Cumberland County, NJ. In line with this mission, the Authority has led several projects at the county’s Solid Waste Complex in Deerfield, NJ. One such project has improved both economic and environmental sustainability for the county by installing an onsite landfill leachate treatment plant.

Reverse Osmosis (RO) Concentrate

The Solid Waste Complex, like all landfills, generates landfill leachate. Landfill leachate is a strongly polluted wastewater product of decomposition of organic fractions of landfill material and water when rain falls onto a landfill. The Authority operates a treatment facility using a combination of ultra-filtration and reverse osmosis (RO) systems. The system, shown in Figure 2, removes contaminates and generates clean water. Clean leachate “permeate” is directly discharged under a state permit. The contaminates, however, are separated into a concentrated wastewater stream, called RO Concentrate, which is generally three to four times the strength of raw leachate, and which requires further treatment for disposal.

Rising Leachate Disposal Costs

Changes in regulation and a requirement to have multiple disposal options forced the Authority to haul significant amounts of the concentrated liquid over 40 miles to the Delaware County Regional Water Quality Authority (DELCORA) in Chester PA. With 25 truck trips per week, transport and disposal costs rose to over $1M per year. Additionally, the Authority recognized important environment impacts and risks associated with so many trucks on the road hauling concentrated leachate.

The Authority turned to its partner, Energy Power Partners (EPP), to help solve its leachate concentrate disposal problem. The Authority first partnered with EPP to install a renewable landfill gas-to-energy plant, which began operations in November 2008. EPP is a private market fund manager that specializes in developing renewable energy projects. EPP owns and operates the landfill gas-to-energy plant located at the Solid Waste Complex. The plant uses three Caterpillar 3520 engines to generate 4.8 MW of renewable electricity.

ROVAP™ – RO Concentrate Evaporation

ROVAP™ stands for On-site Reverse Osmosis Concentrate Evaporation. Heartland’s LM-HT® Concentrator uses a direct contact approach to evaporation, which is ideal for handling challenging wastewater including RO Concentrate. In early 2018, EPP saw an opportunity to help the Authority address its RO concentrate disposal challenges and increase the overall efficiency of the landfill gas-to-energy plant at the same time by beneficially using the existing engine waste heat to evaporate concentrated leachate using Heartland’s LM-HT Concentrator®. The Heartland Concentrator was designed and patented for using waste heat from engines or turbines beneficially to evaporate wastewater. The use of Waste Heat is a classic cogeneration solution.

The Authority’s ROVAP™ solution uses ~900°F engine exhaust from three Caterpillar 3520 engines to evaporate RO Concentrate. Shown in Figure 3, the exhaust is ducted together and transferred to the Heartland Concentrator™, which evaporates the RO Concentrate.The Heartland Concentrator operates under slight negative pressure and pulls the heat across wastewater using a direct contact approach. Additionally, heat from jacket loss is re-used to pre-heat feed water and increase the efficiency of the process.

evaporation in the Heartland Concentrator™.

For the Solid Waste Complex, The ROVAP™ solution has several important benefits. By beneficially using the engine exhaust and jacket water, EPP was able to increase overall energy efficiency of the plant. The thermal energy is used to evaporate the RO Concentrate, dramatically reducing one of the largest expenses of the landfill and taking trucks off the road. In the same project, the Authority both saved cost and reduced the carbon footprint of the landfill.

Results

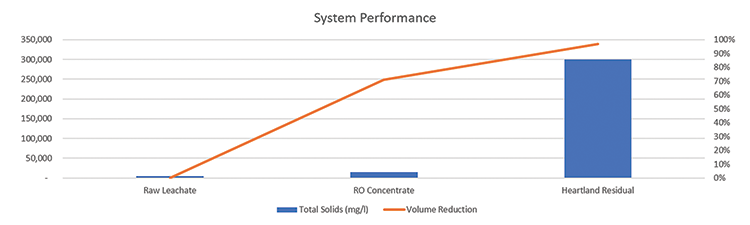

EPP began operation of the Heartland Concentrator™ in January of 2021. The project has been considered successful both economically and environmentally. Chart 1 shows the water treatment performance of the leachate treatment system between June 1 and August 31, 2021. Total solids concentration increased from 5,000 mg/l in the raw leachate to more than 300,000 mg/l in the Heartland residual. This residual concentration corresponded with an over 98 percent total system volume reduction. The remaining highly concentrated residual waste slurry is suitable for landfill disposal, which further reduces the requirements for offsite disposal.

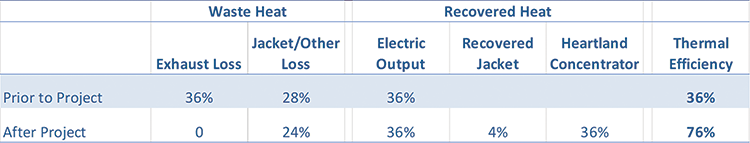

Table 1 shows the improvement in energy efficiency associated with the capture and beneficial reuse of the engine exhaust. By increasing energy efficiency to more than 75 percent, the Authority has reduced its carbon footprint and taken steps toward achieving its sustainability goals.

A Successful Partnership

Onsite leachate treatment reduces cost and removes trucks from the road. Every eliminated trip reduces environmental risk of hauling leachate around the state of NJ and further shrinks the carbon footprint of the solid waste complex by eliminating truck emissions and reducing energy required for treatment by the local wastewater treatment plant.

Prior to installing the concentrator, the solid waste complex was hauling 25 trucks per week of RO Concentrate to wastewater treatment plants for disposal. Due to its partnership with EPP and Heartland, the Authority has reduced their annual disposal costs by 20 to 25 percent while increasing the efficiency of their energy plant. Said President/CEO of The Authority Gerard Velazquez, III. “The ability to implement these programs while creating

environmentally friendly and sustainable systems is integral to the ongoing operations of The Authority and its partners.” | WA

Key Takeaways

• ROVAP—ROVAP™ is On-site Leachate Reverse Osmosis (RO) Concentrate Evaporation using direct contact evaporation from Heartland Water Technology

• Environmental Sustainability—Through onsite evaporation, The Authority is taking significant steps toward achieving their sustainability goals

• Economic Benefits— On-site RO Concentrate treatment reduces overall leachate treatment costs

For more information, e-mail [email protected] or visit www.heartlandtech.com.